Thermal polymerization preparation method of manganides solid solution positive material

A cathode material, thermal polymerization technology, applied in battery electrodes, electrical components, circuits, etc., can solve the problems of poor product performance consistency, unsatisfactory rate performance, large irreversible capacity, etc. Outstanding performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

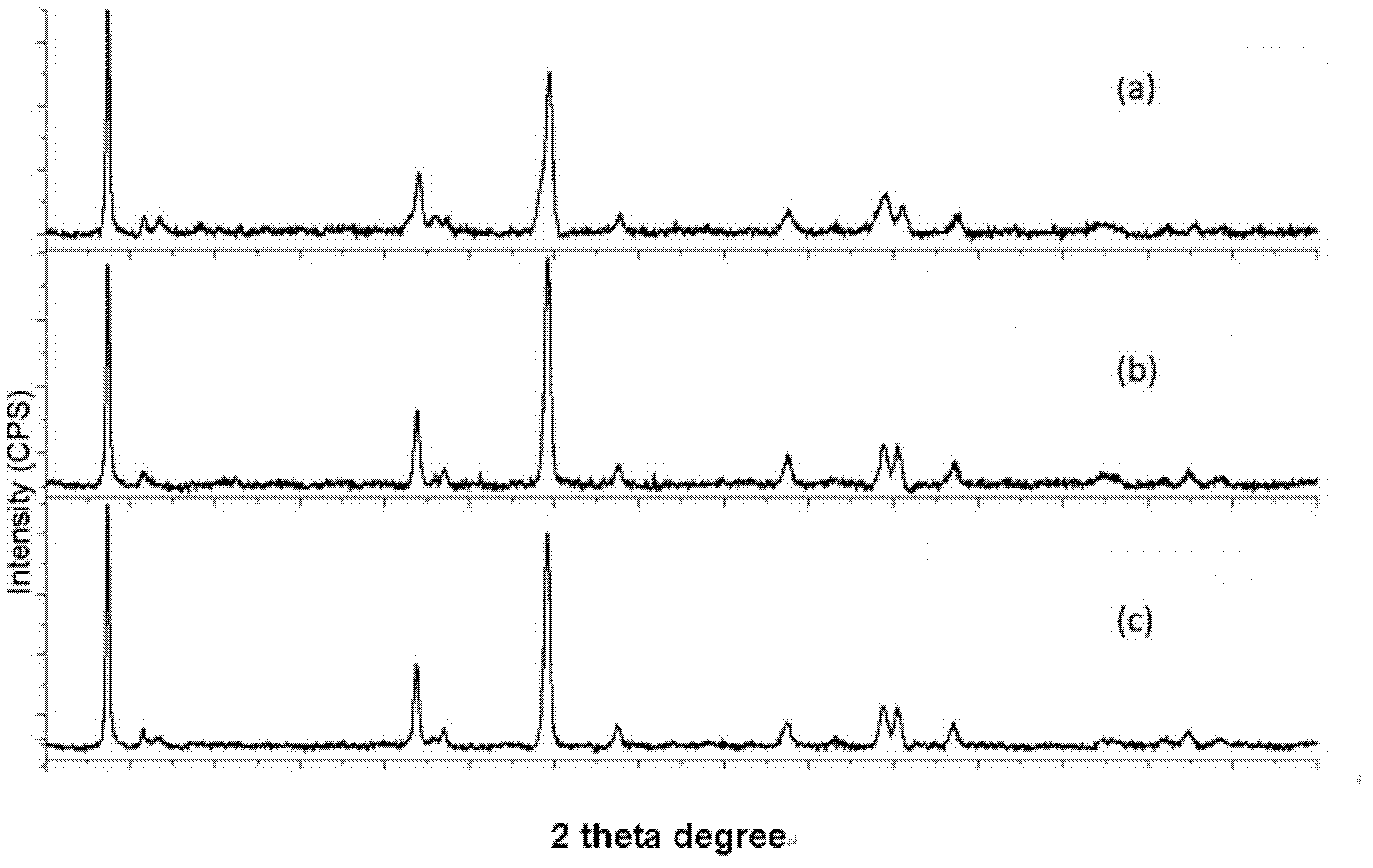

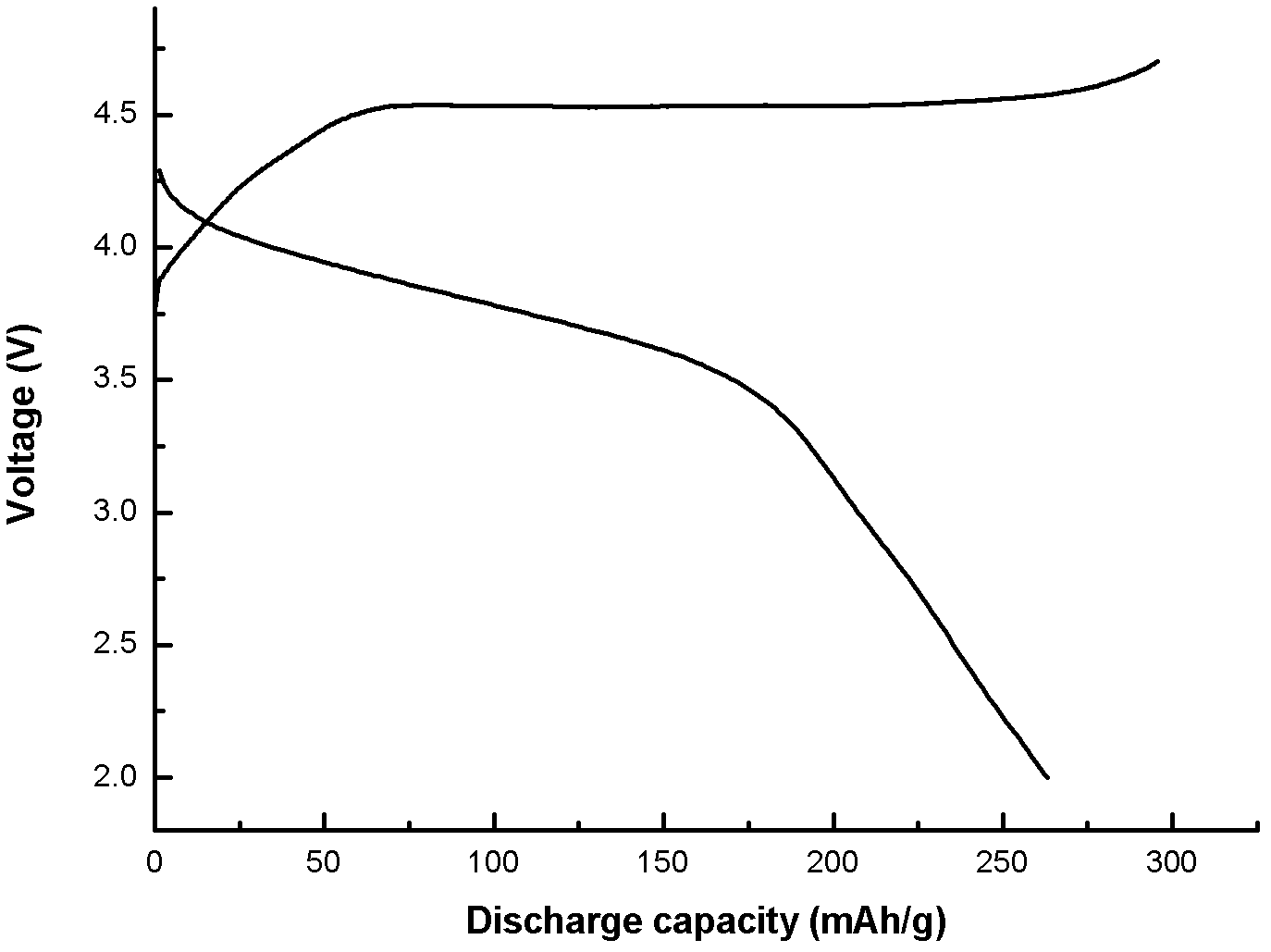

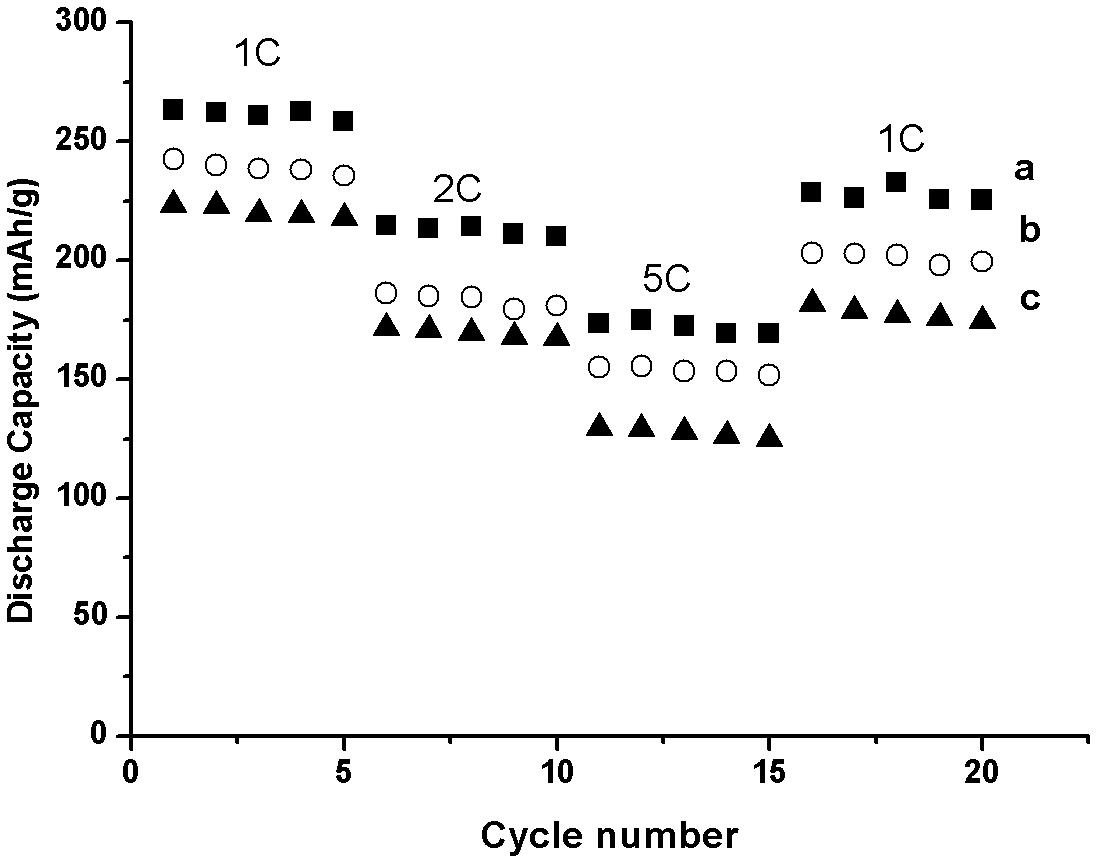

Embodiment 1

[0026] 1. Prepare 1L of citric acid and ethylene glycol solution, and the mass ratio of the two substances is 1:4.

[0027] 2. According to the molecular formula Li[Ni 0.35 Li 0.1 mn 0.55 ]O 2 Lithium acetate, nickel acetate, manganese acetate are weighed in the ratio of Li, Ni, Mn, wherein lithium, nickel, manganese metal ion molar percentage is 0.11:0.035:0.055, metal salt is dissolved in deionized water, forms metal ion total A mixed metal salt solution with a concentration of 0.5mol / L.

[0028] 3. Add the solution in 2 into the mixed solution in 1, adjust the pH of the solution to 5 with 0.5 mol / L ammonia water, and stir vigorously at 80°C for 2 hours until the metal salt is completely dissolved and gradually forms a gel.

[0029] 4. Take out the gel obtained in 3 and place it in a vacuum drying oven, and dry it at 140°C for 12 hours to form a blocky precursor.

[0030] 5. Put the precursor into a muffle furnace, heat up to 450°C at a rate of 20°C / min for pre-calcinat...

Embodiment 2

[0033] 1. Prepare 1L of citric acid and ethylene glycol solution, and the mass ratio of the two substances is 1:4.

[0034] 2. According to the molecular formula Li[Ni 0.35 Li 0.1 mn 0.55 ]O 2 Lithium acetate, nickel acetate, manganese acetate are weighed in the ratio of Li, Ni, Mn, wherein lithium, nickel, manganese metal ion molar percentage is 0.11:0.035:0.055, metal salt is dissolved in deionized water, forms metal ion total A mixed metal salt solution with a concentration of 0.2mol / L.

[0035] 3. Add the solution in 2 into the mixed solution in 1, adjust the pH of the solution to 5 with 0.5 mol / L ammonia water, and stir vigorously at 80°C for 2 hours until the metal salt is completely dissolved and gradually forms a gel.

[0036] 4. Take out the gel obtained in 3 and place it in a vacuum drying oven, and dry it at 140°C for 12 hours to form a blocky precursor.

[0037] 5. Put the precursor into a muffle furnace, heat up to 450°C at a rate of 20°C / min for pre-calcinat...

Embodiment 3

[0040] 1. Prepare 1L of citric acid and ethylene glycol solution, and the mass ratio of the two substances is 1:4.

[0041] 2. According to the molecular formula Li[Ni 0.35 Li 0.1 mn 0.55 ]O 2 Lithium sulfate, nickel sulfate, manganese sulfate are weighed in the ratio of Li, Ni, Mn, wherein lithium, nickel, manganese metal ion molar percentage is 0.11:0.035:0.055, metal salt is dissolved in deionized water, forms metal ion total A mixed metal salt solution with a concentration of 0.5mol / L.

[0042] 3. Add the solution in 2 into the mixed solution in 1, adjust the pH of the solution to 5 with 0.5 mol / L ammonia water, and stir vigorously at 80°C for 2 hours until the metal salt is completely dissolved and gradually forms a gel.

[0043] 4. Take out the gel obtained in 3 and place it in a vacuum drying oven, and dry it at 140°C for 12 hours to form a blocky precursor.

[0044] 5. Put the precursor into a muffle furnace, heat up to 450°C at a rate of 20°C / min for pre-calcinat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com