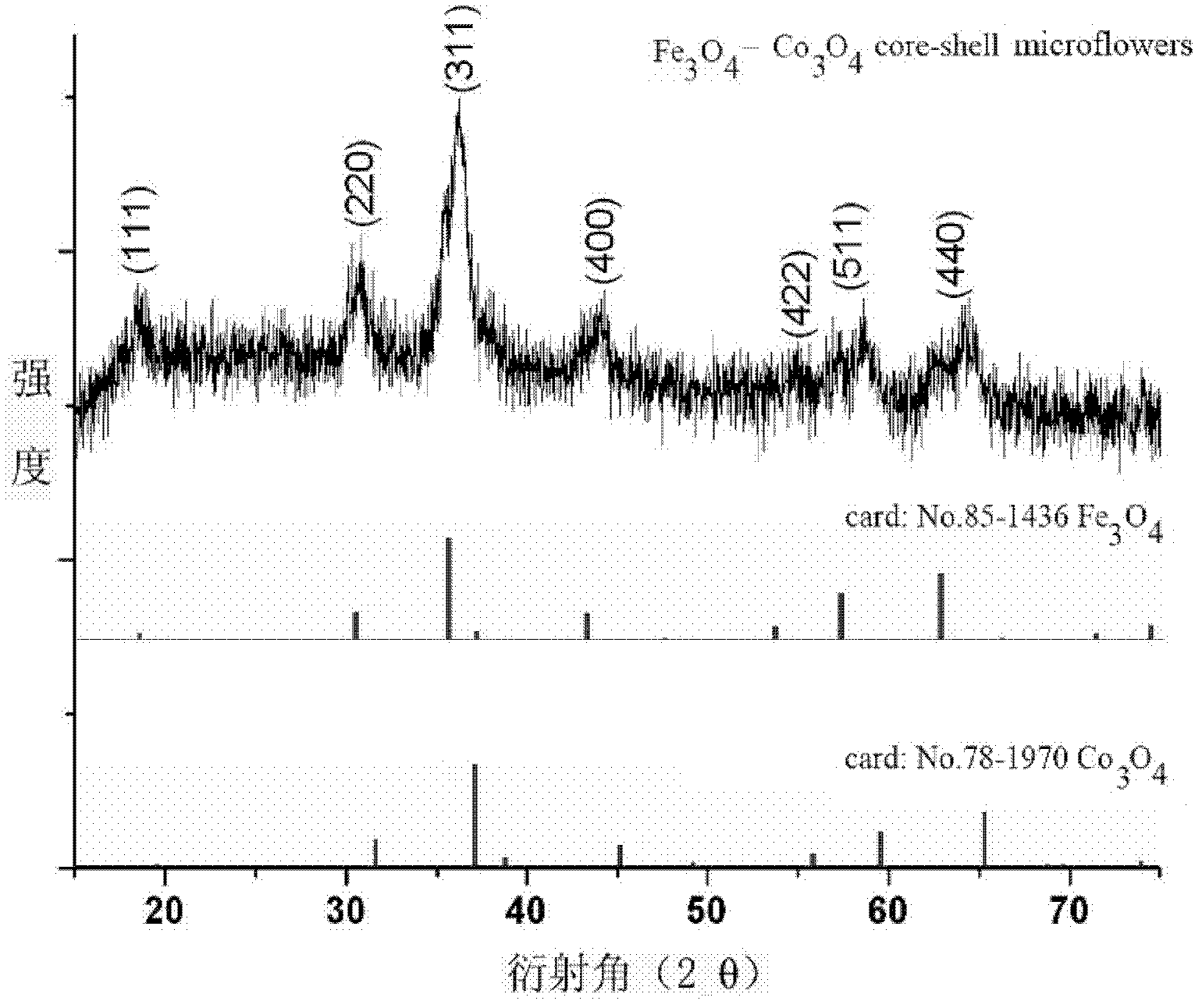

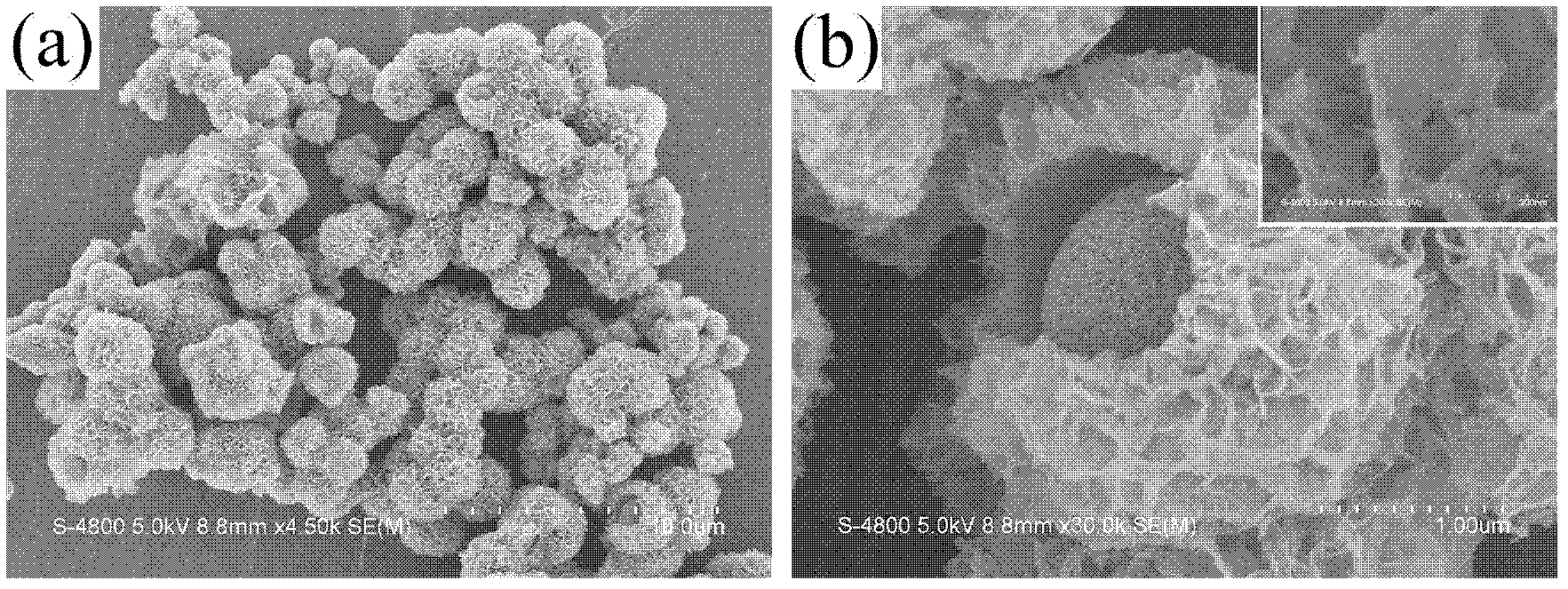

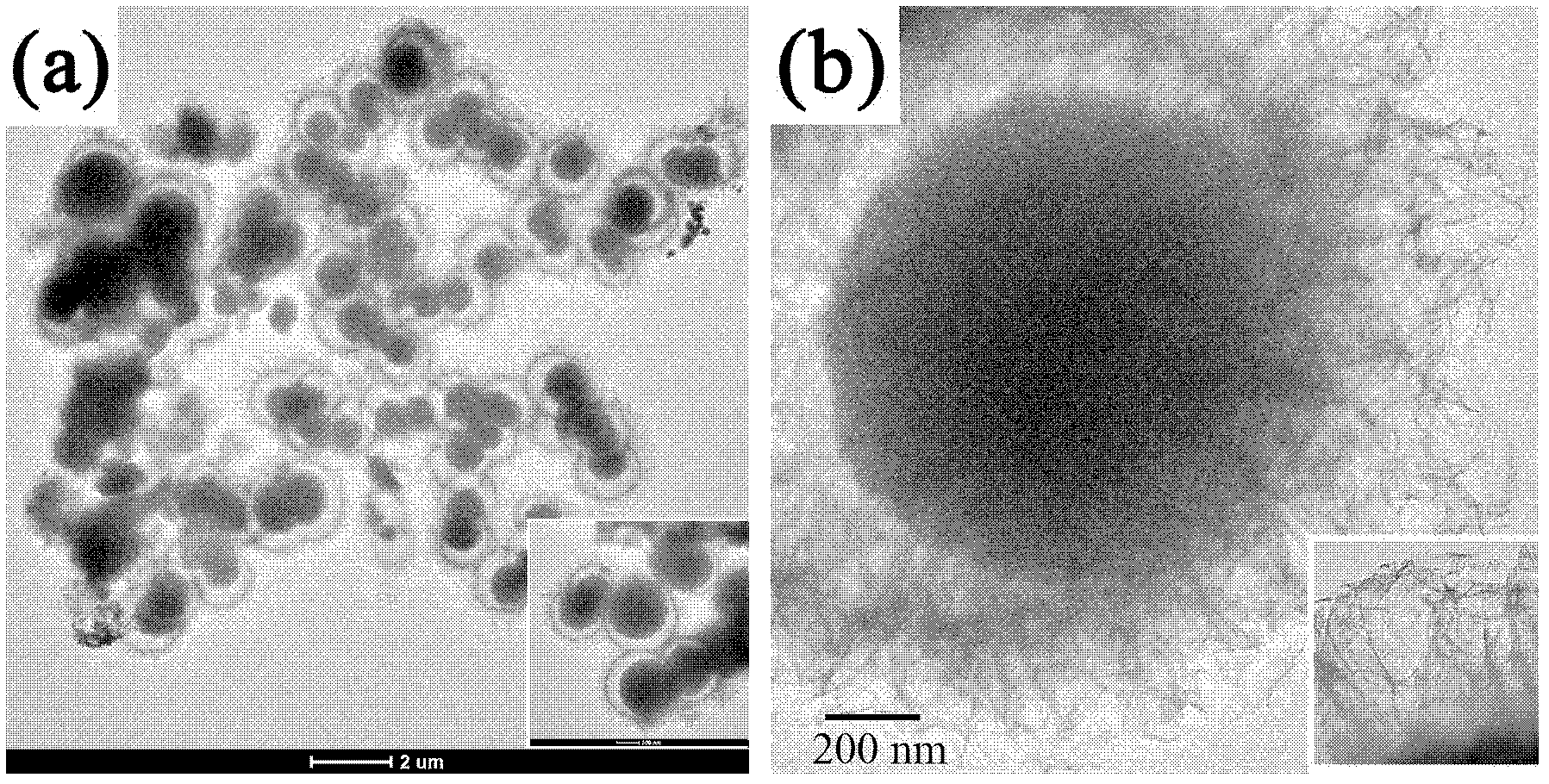

Preparation method and application of Fe3O4-Co3O4 porous magnetic composite material

A magnetic composite material, cobalt tetroxide technology, applied in electrical components, battery electrodes, circuits, etc., to achieve the effects of simple preparation method, simple and controllable method, and special appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] 1. Preparation of ferroferric oxide-cobalt trioxide yolk-shell porous magnetic composite material:

[0035] (a) mixing step: add 0.1221g cobalt chloride and ferrous sulfate 0.0634g to 20ml volume ratio at room temperature in the mixed solvent of water, ethanol, butanol of 120:100:1, and add 0.16g urea and 0.10g trisodium citrate, fully stirred to make yellow-brown solution, pH is 5;

[0036] (b) Heating step: heating the solution prepared in step (a) to 120° C., and the reaction time is 10 hours;

[0037] (c) drying step: cooling, filtering, and washing the precipitate obtained in (b) heating step to neutrality, and drying at 60°C to obtain a non-porous yolk-shell material;

[0038] (d) Calcining the product obtained in (c) at a temperature of 300° C. for 1 hour. The calcination does not require any protective gas, just heating with air and cooling to room temperature. The process is to convert the non-porous material obtained in the (c) stage into a porous ferric oxi...

Embodiment 2

[0047] 1. Preparation of ferroferric oxide-cobalt trioxide yolk-shell porous magnetic composite material:

[0048](a) Mixing step: Add 0.1223g cobalt chloride and 0.0634g ferrous sulfate mixture to water, ethanol, butanol solvent with a volume ratio of 100:100:3 at room temperature, and add 0.16g urea and 0.10g Trisodium citrate, fully stirred to make a yellow-brown solution, pH 5;

[0049] (b) Heating step: heating the solution prepared in step (a) to 120°C for a reaction time of 5 hours;

[0050] (c) drying step: cooling, filtering, and washing the precipitate obtained in (b) heating step to neutrality, and drying at 60°C to obtain a non-porous yolk-shell material;

[0051] (d) Calcining the product obtained in (c) at a temperature of 300° C. for 1 hour. The calcination does not require any protective gas, just heating with air and cooling to room temperature. The process is to transform the non-porous material obtained in the (c) stage into a porous ferric oxide-cobalt te...

Embodiment 3

[0053] 1. Preparation of ferroferric oxide-cobalt trioxide yolk-shell porous magnetic composite material:

[0054] (a) Mixing step: add 0.1465g cobalt chloride and 0.0645g ferrous sulfate mixture to the water, ethanol, butanol solvent with a volume ratio of 120:100:1 at room temperature, and add 0.16g urea and 0.10g Trisodium citrate, fully stirred to make a yellow-brown solution, pH 5;

[0055] (b) Heating step: heating the solution prepared in step (a) to 150° C., and the reaction time is 10 hours;

[0056] (c) drying step: cooling, filtering, and washing the precipitate obtained in (b) heating step to neutrality, and drying at 60°C to obtain a non-porous yolk-shell material;

[0057] (d) Calcining the product obtained in (c) at a temperature of 300° C. for 1 hour. The calcination does not require any protective gas, just heating with air and cooling to room temperature. The process is to convert the non-porous material obtained in the (c) stage into a porous ferric oxide-...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com