LED (Light Emitting Diode) packaging structure using rear earth element doped transparent ceramic as base

A technology of LED packaging and transparent ceramics, which is applied in the direction of electrical components, circuits, semiconductor devices, etc., can solve the problems of reduced reflectance of light bands, accelerated light decay, yellowing and discoloration of metal Ag films, etc., and achieves the effect of high insulation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

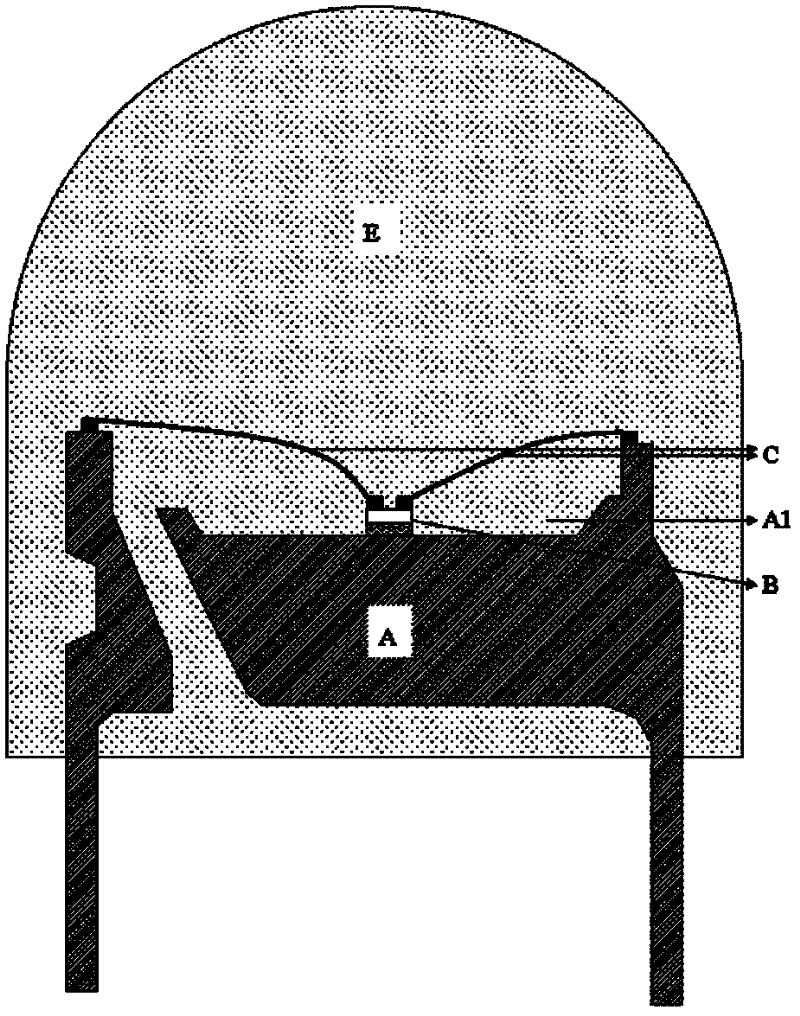

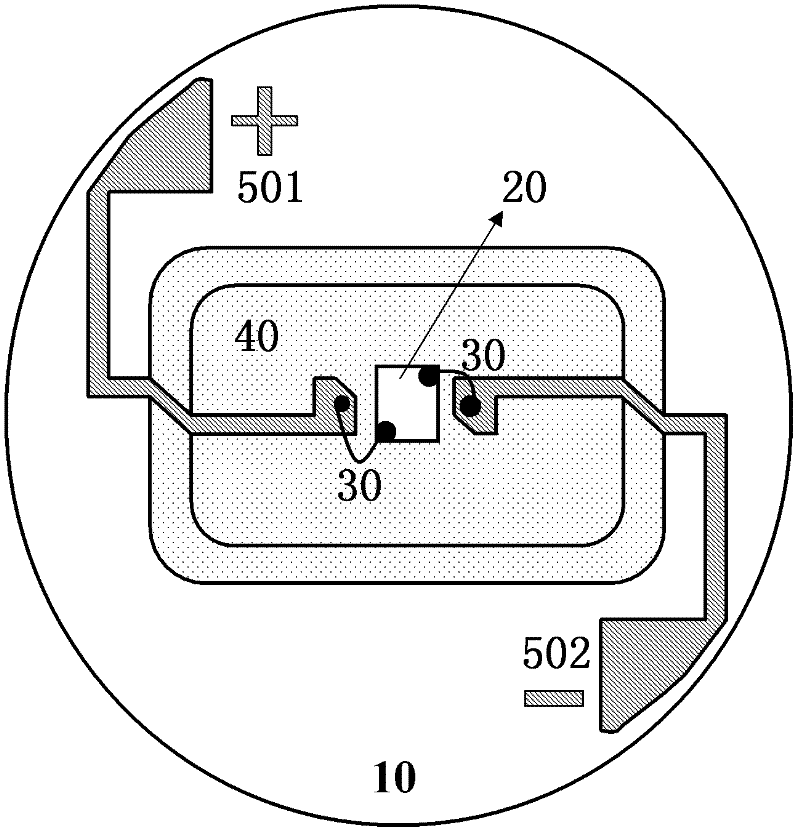

[0027] Prepared by injection molding or slip casting or isostatic pressing figure 2 and image 3 Doped Ce 2 o 3 The YAG transparent ceramic base 10 with an atomic percentage of 0.15% is sintered at high temperature in vacuum or in an atmosphere. The transmittance of ceramics in the region greater than the wavelength of green light is greater than 80%, and the transmittance curve is as follows Figure 5 shown. On the prepared ceramic base, photolithography and magnetron sputtering techniques are used to form such as figure 2 and image 3 Patterned copper metal electrodes 501 and 502 are shown.

[0028] The blue light LED chip 20 is fixed on the YAG ceramic base 20 by using a crystal bonding machine and a transparent crystal bonding glue 201. The dominant wavelength of the chip is 430-435nm, and at 150 o Bake in an oven at C for 2 hours to cure the die-bonding glue.

[0029] Using a gold wire machine and gold wire 30, the positive and negative electrodes of the LED chi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com