Insulated gate bipolar transistor (IGBT) with low-conductivity saturation voltage drop and manufacturing method for IGBT

A low-conduction, semiconductor technology, used in semiconductor/solid-state device manufacturing, semiconductor devices, electrical components, etc., can solve problems such as the increase of sheet processing equipment, improve short-circuit current withstand capacity, reduce resistivity, and enhance impact resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0078] The present invention will be further described below in conjunction with specific drawings and embodiments.

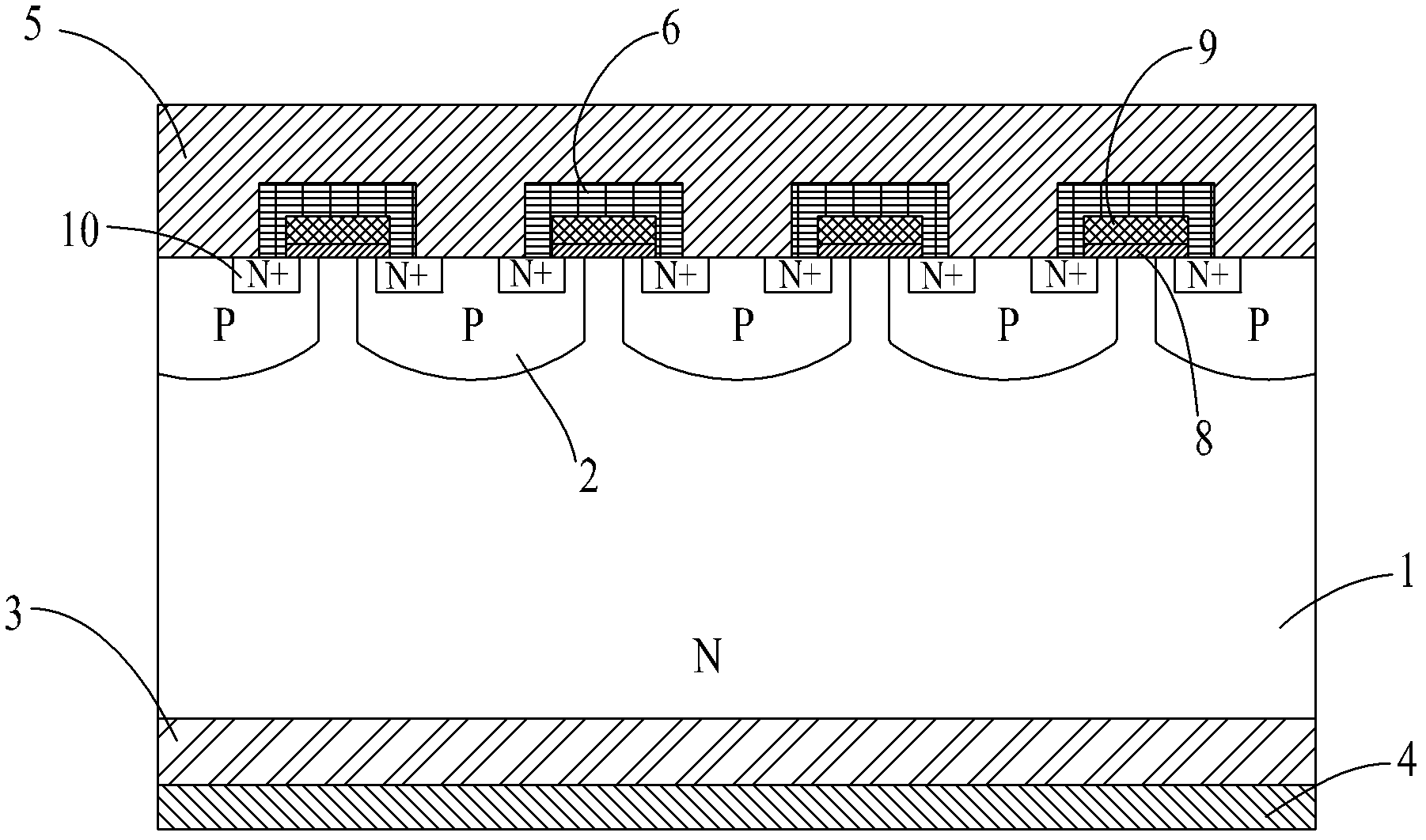

[0079] Such as image 3 , Figure 4 , Figure 5 , Image 6 , Figure 7 with Figure 18 Shown: the present invention takes N-type IGBT as an example to illustrate the structure and corresponding working principle of the present invention.

[0080] Such as Figure 5 As shown, in the top view of the IGBT device, the device includes an active region 15 and a terminal protection region 16 surrounding the active region 15; the active region 15 includes conductive polysilicon 9 arranged in parallel strips, so The conductive polysilicon 9 separates the P well layer 2 in the active region 15 into a P well layer first region 11 and a P well layer second region 12, and the P well layer first region 11 and the P well layer second region 12 alternately and regularly arranged, the first region 11 of the P well layer is provided with an N+ implantation region 10, and a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com