Method for quickly measuring content of phosphorus, lead and zinc in industrial ferrous dust

A technology for rapid determination of zinc content, applied in the field of chemical analysis, can solve the problems of cumbersome sample decomposition operation, unfavorable environmental protection and occupational health, and inability to meet the accuracy requirements of smelting analysis.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention further illustrates the content of the invention through the examples, but is not limited by the examples.

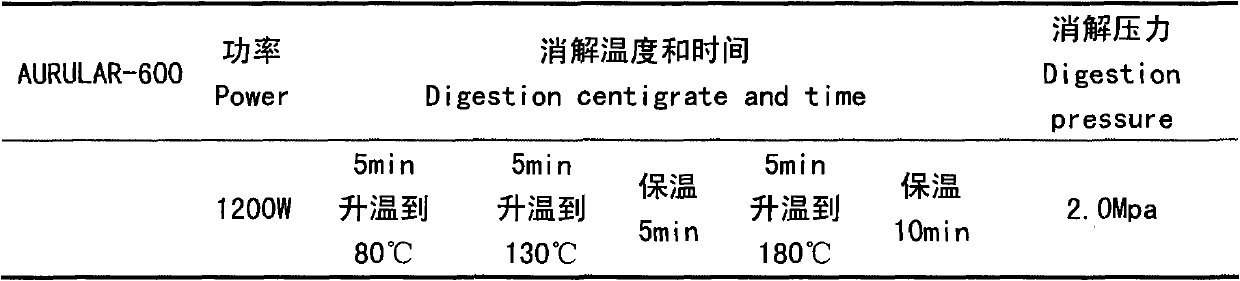

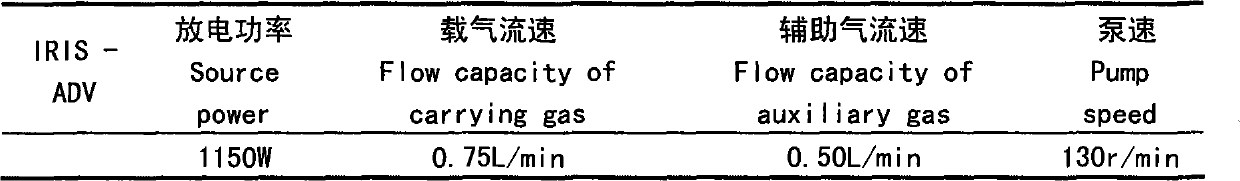

[0028] Equipment used: IRIS Advantage ER / S full-spectrum direct-reading plasma emission spectrometer (TJA, USA); AURULAR-600 pressure self-controlled closed microwave sample dissolution system, power 1200W;

[0029] Reagents used: high-purity water; chemical reagents are of superior grade. Hydrochloric acid, nitric acid (ρ1.42g / mL), perchloric acid (ρ1.67g / mL), hydrofluoric acid.

[0030] Phosphorus, lead, zinc standard stock solution: use the National Standard Center to develop national standard reagents, 1mg / mL.

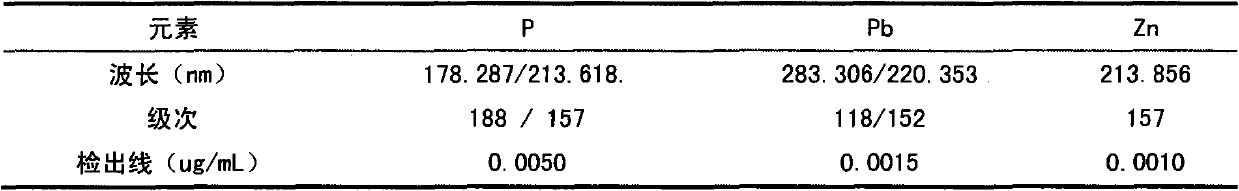

[0031] Determination of phosphorus, lead and zinc content in gas ash, blast furnace ash, dedusting ash and converter mud:

[0032]Each sample sample is dried at 105°C, cooled, weighed 0.1O00g (accurate to 0.1mg) in a magnetic dish covered with a layer of quantitative filter paper, and in a high-temperature furnace, gradually in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com