Pull-type asphalt highway maintenance vehicle

A road maintenance and trailer technology, which is applied in the directions of roads, roads, and road repairs, can solve the problems of difficult control of oil-to-stone ratio, high labor intensity, manual mixing, etc., and achieves simple structure, less equipment failure, and convenient maintenance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

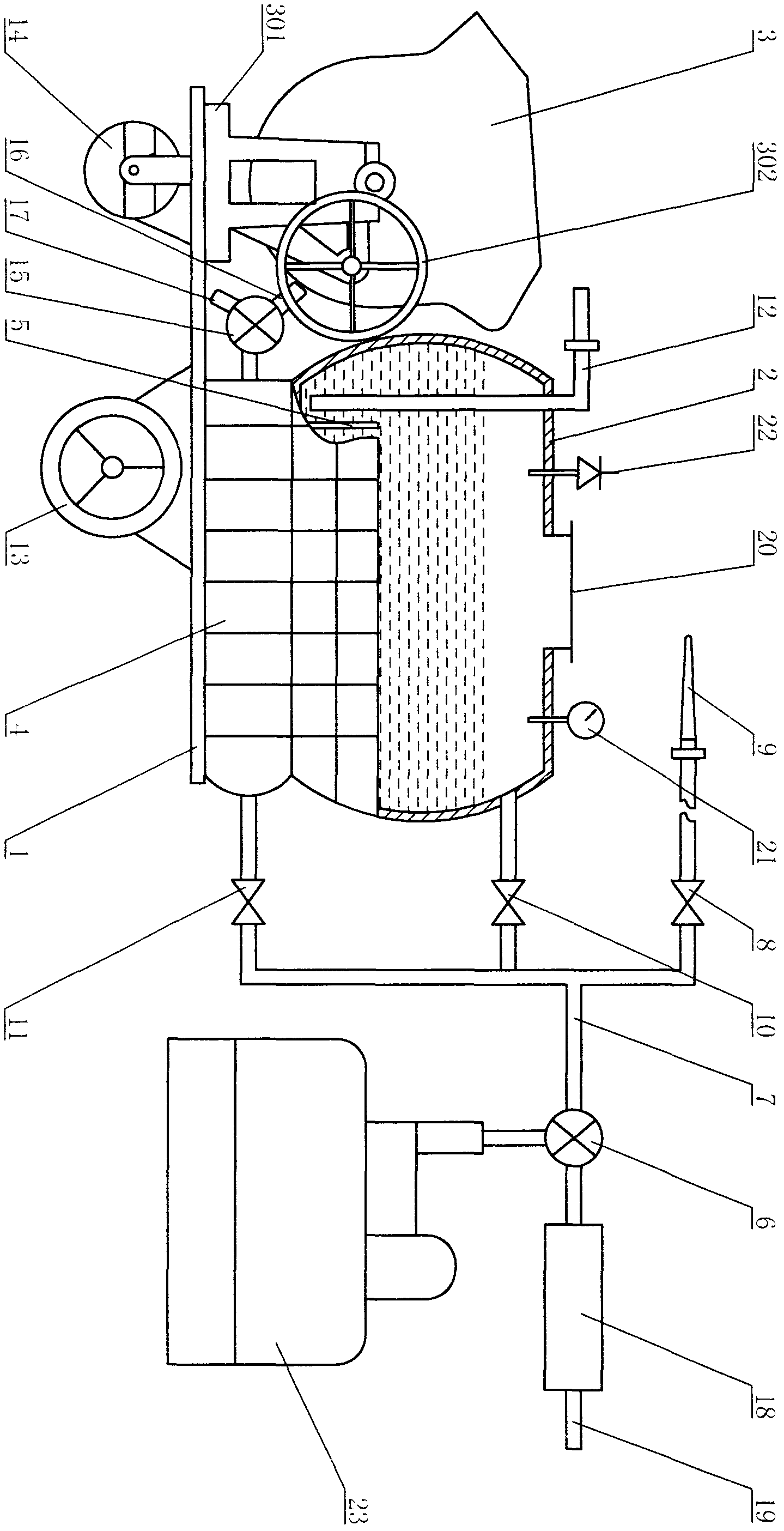

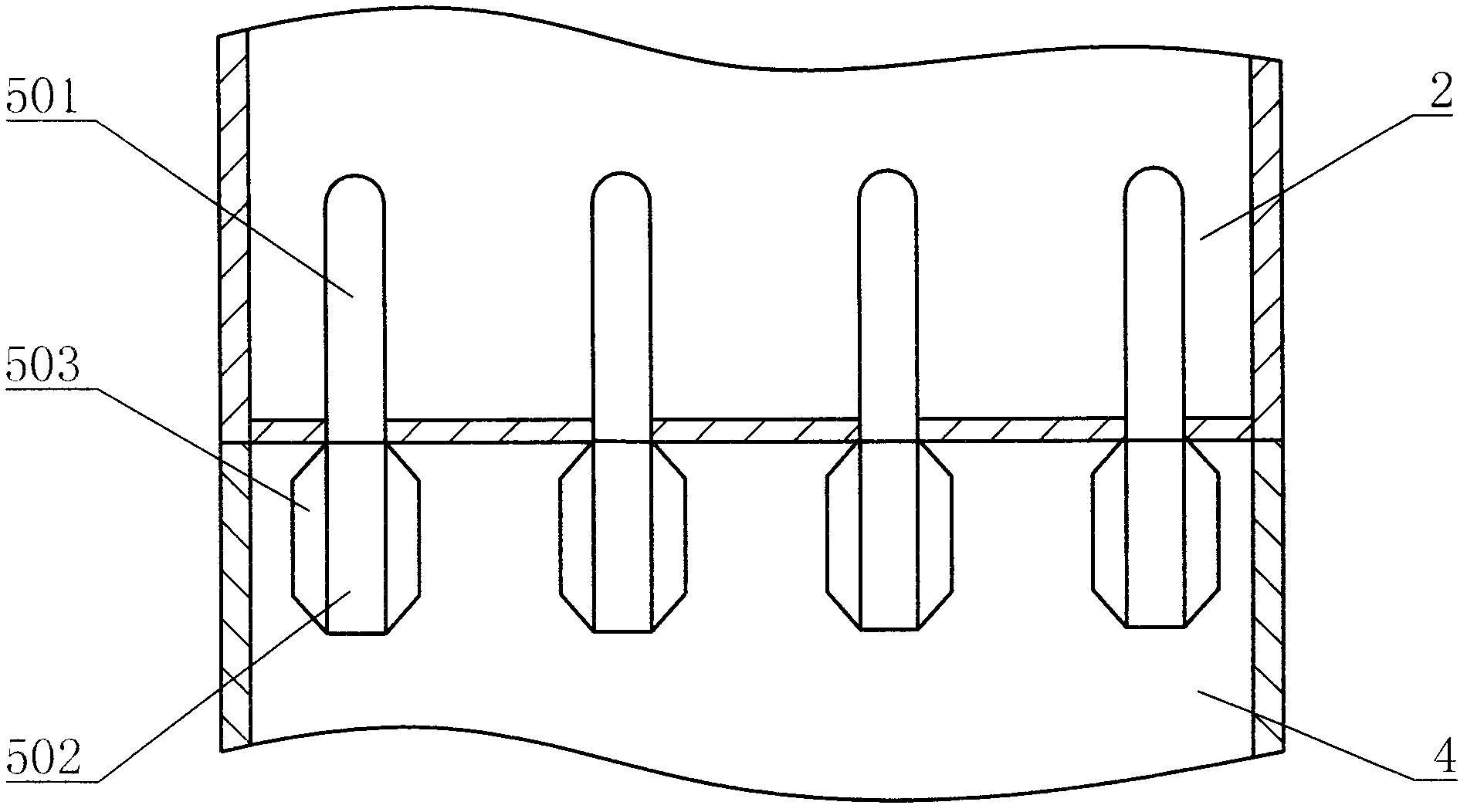

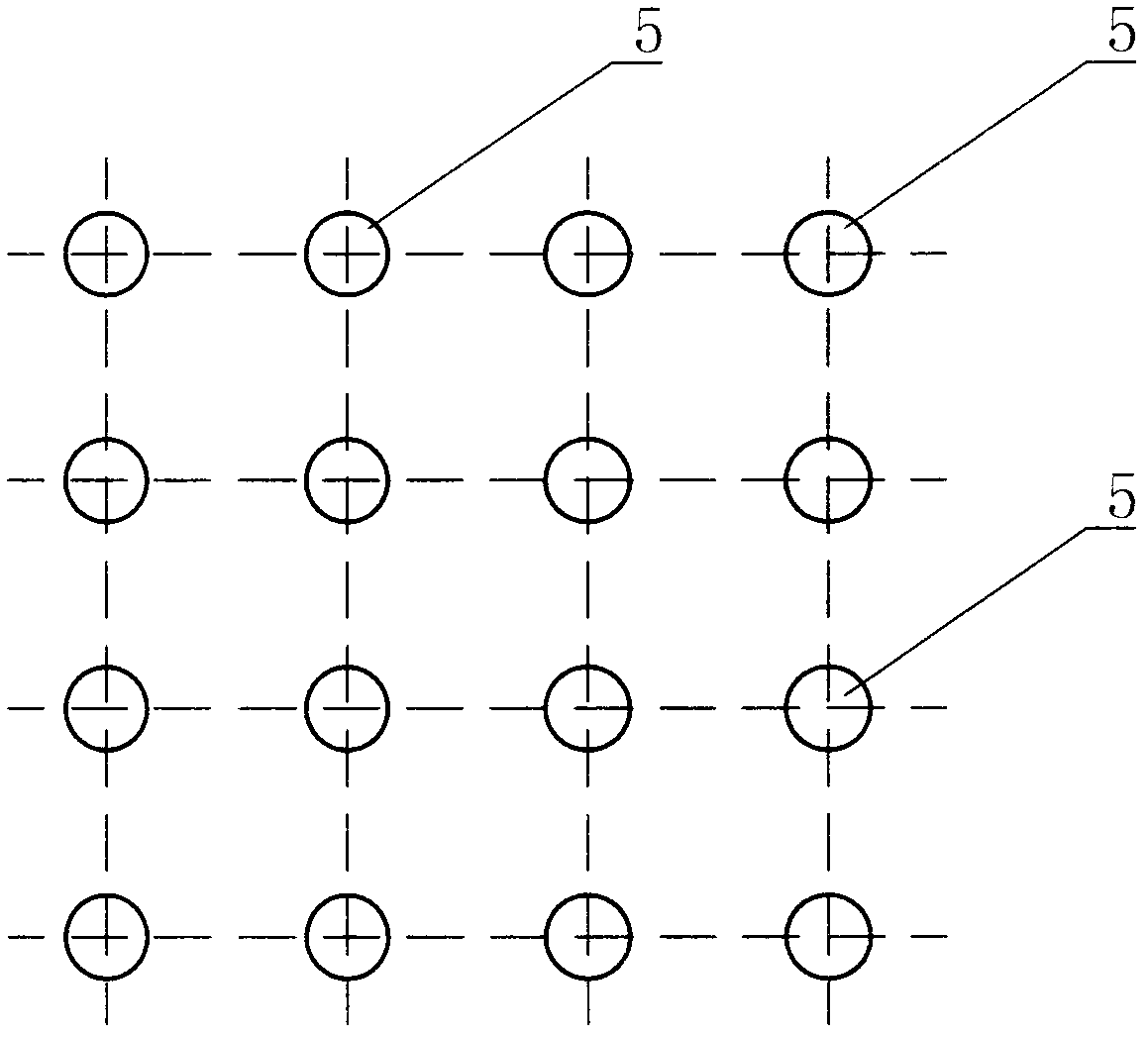

example 1

[0029] The trailer-type asphalt road maintenance operation vehicle of the present invention comprises a chassis 1, a heating device composed of a heat collecting box 4 and a heat pipe 5, an oil storage tank 2 and a mixer 3 arranged on the chassis 1, and an oil storage tank 2 and a mixer 3 arranged on the chassis 1 and the storage The heating device between the oil tanks 2, and the exhaust gas recovery and distribution device composed of the three-way valve 6 connected to the exhaust pipe of the internal combustion engine 23 and the gas transmission pipeline 7 provided through the three-way valve 6; wherein the heat pipe 5 is arranged in the heat collection box 4 , one end extends into the oil storage tank 2, absorbs heat from the heat collection tank 4, transfers it to the oil storage tank 2, and heats the asphalt; the upper part of the oil storage tank 2 is provided with an oil outlet pipe 12, and the oil outlet of the oil outlet pipe 12 extends into the The inner bottom of th...

example 2

[0031] The present invention pulls type asphalt road maintenance operation vehicle, as figure 1 As shown, its underframe 1 bottom is provided with supporting wheel 13 and the roller 14 that can lift, so that it can be easily towed and walked, maneuverable and flexible, and can also carry out suppression operations.

[0032] Wherein the mixer 3 is arranged on the bottom frame 1 through the bracket 301, and the bracket 301 is provided with a hand wheel 302 for controlling the rotation of the mixer 3, so that the mixer 3 can conveniently pour out the stirred materials for easy control.

[0033] The heating nozzle 16 and the exhaust port 17 are set on the side of the heat collecting box 4 corresponding to the mixer 3 through the reversing valve 15, and the outlet of the heating nozzle 16 is set at the bottom of the mixer 3. When the material needs to be heated or kept warm, the reversing valve can be opened 15. Use the high-temperature exhaust gas to heat the bottom of the mixer 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com