Non-magnetic hard-section nickel austenitic stainless steel and preparation method thereof

A technology of austenitic stainless steel and a manufacturing method, applied in the field of non-magnetic hard nickel austenitic stainless steel and its manufacturing, can solve the problems of reduction and low corrosion resistance, and achieve cost reduction, low cost and cost reduction. Effect

Inactive Publication Date: 2012-07-11

BAOSHAN IRON & STEEL CO LTD

View PDF9 Cites 29 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

For example, CN1129259A discloses a nitrogen-containing austenitic stainless steel that can save nickel and chromium. Mn and N are used to replace part of Ni, and the Ni content is significantly reduced compared with 8% in 304. However, in order to ensure that the full austenite phase is obtained at room temperature, The Cr content in the composition is also significantly reduced to 10-15%, which will result in much lower corrosion resistance than 304

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 2

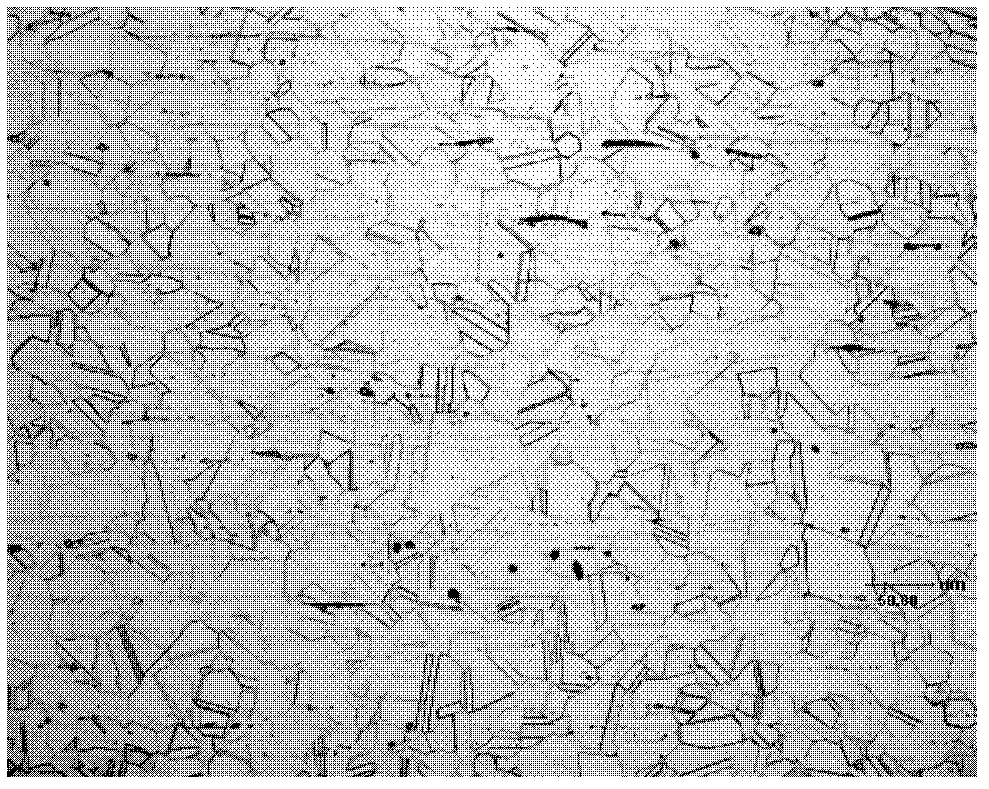

[0063] The alloy metallographic diagram of embodiment 2 is as figure 1 As shown (austenite structure at room temperature), the sample was electrolytically corroded, the etchant was saturated oxalic acid solution, and the corrosion current was 0.2-0.4A / cm 2 .

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| yield strength | aaaaa | aaaaa |

Login to View More

Abstract

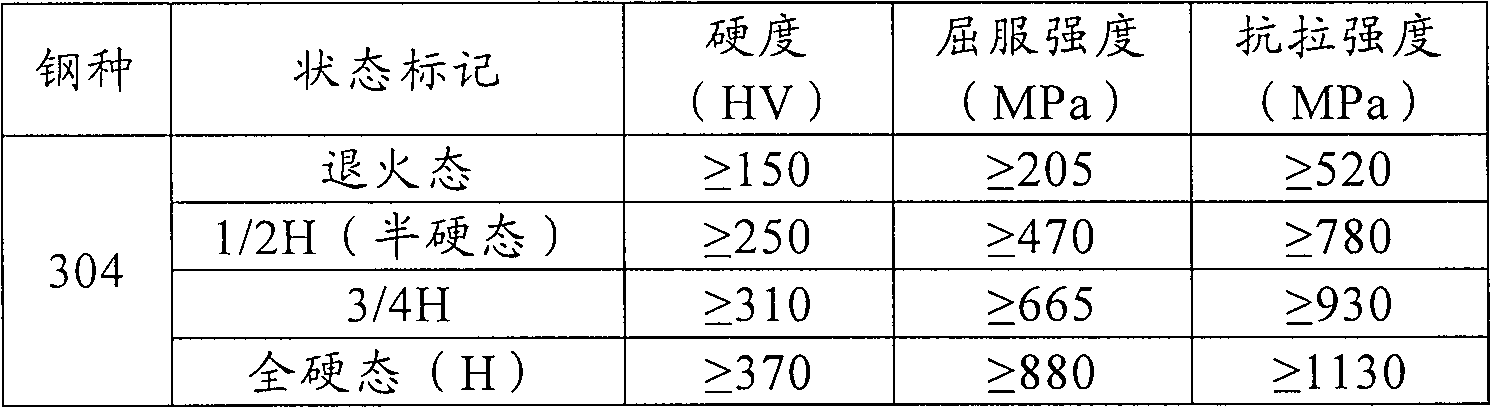

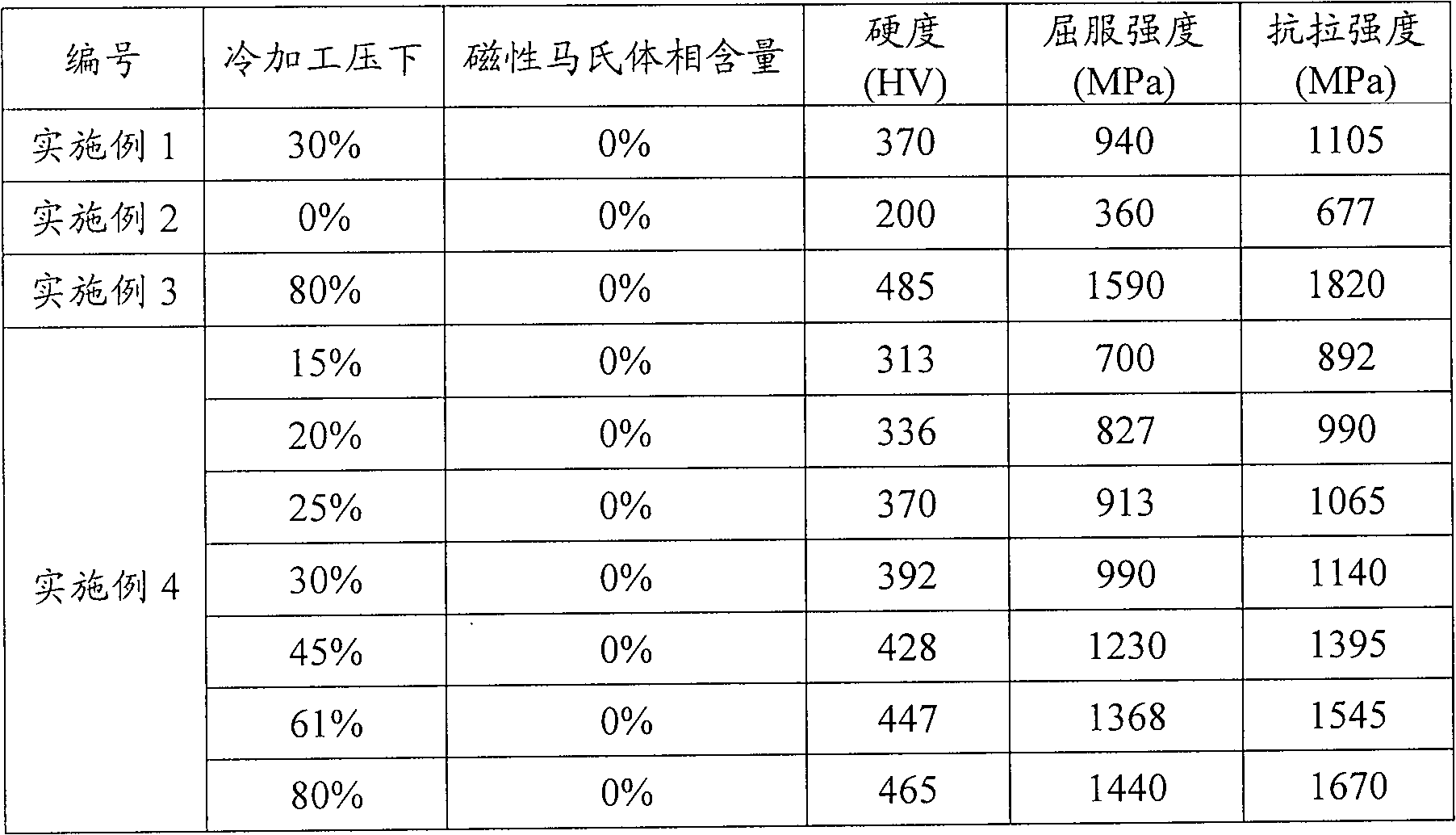

The invention relates to non-magnetic hard-section nickel austenitic stainless steel. The non-magnetic hard-section nickel austenitic stainless steel comprises the following chemical components by weight percentage: 0.07-0.12 percent of C, 0.2-1.0 percent of Si, 6.5-9.0 percent of Mn, 17.0-18.0 percent of Cr, 3.5-4.5 percent of Ni, 0.16-0.35 percent of N, 0.51-0.95 percent of Mo, 0.5-2.0 percent of Cu, as well as optionally one or two of 0.02-0.1 percent of V and 0.02-0.1 percent of Nb, and Fe and inevitable impurities in balancing amount. the Ni element is replaced by the C element and the N element to prepare an austenite tissue at room temperature, so that the content of the expensive Ni element can be effectively reduced, thereby reducing the cost; through the synergistic effect of Cr, Mo and N, the pitting resistance equivalent PREN of the material is ensured to be more than or equal to 18, and the corrosion resistance is improved and is equivalent to that of 304; by controlling the Md30 / 50 temperature to be lower than -35 DEG C and the lowest Md30 / 50 temperature to be -125 DEG C, after reduction of the cold rolling pressure by 0-80 percent, the yield strength of the material is 360-1590 MPa, but no Martensite phase is formed, so that the material keeps a non-magnetic characteristic, can be widely applied to electronics, apparatuses and instruments and other industries; and compared with the cost of 304 and 305, the cost of the material is obviously reduced.

Description

technical field [0001] The invention relates to a nitrogen-containing nickel-intensive austenitic stainless steel and a manufacturing method thereof, in particular to a non-magnetic hard nickel-intensive austenitic stainless steel with excellent corrosion resistance and a manufacturing method thereof. Background technique [0002] Stainless steel hard materials are often used in electronics, instrumentation and other industries. Commonly used stainless steel hard materials are mainly S30400 (304) and S30100 (301) in 300 series austenitic stainless steel. The so-called hard stainless steel refers to quenching and tempering rolling of stainless steel plate or steel strip, giving the steel strip a certain amount of cold rolling reduction, no annealing treatment after cold working, and obtaining hard stainless steel products. Hardened stainless steel is generally stronger and harder than the same material after solution treatment (or annealing treatment), so the material is mor...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): C22C38/58C22C33/04C21D8/02

Inventor 张伟胡锦程江来珠陈炳铨顾学红包磊林隆声

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com