Self-bacteriostasis general emulsion cutting fluid and preparing method thereof

A cutting fluid and self-inhibitory technology, which is applied in the petroleum industry, additives, lubricating compositions, etc., can solve the problems of expensive bactericide, shortened service life, and increased product cost, so as to save anti-rust treatment and reduce product cost. cost, and the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

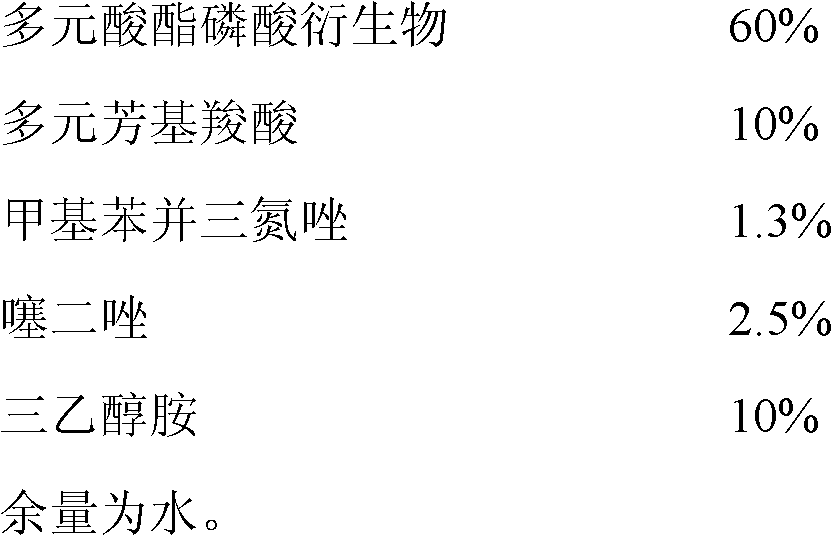

preparation example Construction

[0033] The preparation method of the above-mentioned self-inhibiting type universal emulsified cutting fluid comprises the following steps:

[0034] (1) Preparation of composite corrosion inhibitor

[0035] ① Add tolylbenzotriazole and thiadiazole into water, and heat up to 70-80°C while stirring to dissolve completely;

[0036] ②Add polybasic acid ester phosphoric acid derivatives, polyaryl carboxylic acid and triethanolamine to the solution obtained in step ①, and stir at a temperature of 60-70°C for more than 30 minutes until the solution is uniform and transparent, and the finished composite corrosion inhibitor is obtained;

[0037] (2) Prepared from antibacterial general-purpose emulsified cutting fluid

[0038] ① Add disodium ethylenediamine tetraacetate to base oil or oily agent, and heat up to 50-60°C to dissolve completely;

[0039] ②Add anionic surfactant, monoisopropanolamine, composite corrosion inhibitor, extreme pressure antiwear agent, alkylalanine surfactant ...

Embodiment 1

[0042]

[0043] The preparation method of the above-mentioned self-inhibiting type universal emulsified cutting fluid comprises the following steps:

[0044] (1) Preparation of composite corrosion inhibitor

[0045] ①Add 0.0611 kg of tolylbenzotriazole and 0.1175 kg of thiadiazole into water, and heat up to 70°C while stirring to dissolve completely;

[0046] 2. Add 2.82 kilograms of polyoxyethylene sebacic acid ether phosphate (polyester phosphoric acid derivatives), 0.47 kilograms of phenylmalonic acid (polyaryl carboxylic acid) and 0.47 kilograms of triethanolamine to the solution obtained in step 1. , stirred at 60°C for 50 minutes until the solution was uniform and transparent, and the finished composite corrosion inhibitor was obtained;

[0047] (2) Prepared from antibacterial general-purpose emulsified cutting fluid

[0048] ①Add 1 kg of disodium edetate to 65 kg of 10# engine oil (base oil or oily agent), and heat up to 50°C to completely dissolve it;

[0049] 2....

Embodiment 2

[0052]

[0053]

[0054] The preparation method of the above-mentioned self-inhibiting type universal emulsified cutting fluid comprises the following steps:

[0055] (1) Preparation of composite corrosion inhibitor

[0056] ① Add 0.0585 kg of methyl benzotriazole and 0.1125 kg of thiadiazole into water, and heat up to 80°C while stirring to dissolve completely;

[0057] 2. Add 2.7 kilograms of polyoxyethylene sebacic acid ether phosphate (polyester phosphoric acid derivatives), 0.45 kilograms of phenylmalonic acid (polyaryl carboxylic acid) and 0.45 kilograms of triethanolamine to the solution obtained in step 1. , stirred at 70°C for 50 minutes until the solution was uniform and transparent, and the finished composite corrosion inhibitor was obtained;

[0058] (2) Prepared from antibacterial general-purpose emulsified cutting fluid

[0059] ① Add 1 kg of disodium ethylenediamine tetraacetate to 68 kg of polyol ester (base oil or oily agent), and raise the temperature...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com