Compound pipe manufacturing technology for metallurgically bonding anti-corrosion special alloy lining with pipeline steel outer sleeve

A metallurgical bonding and composite pipe technology, which is applied in the field of liquid or gas conveying high-strength corrosion-resistant composite pipes and composite pipe preparation technology, can solve the problems of low interface bonding force, poor comprehensive mechanical properties, and complicated processing, and achieves improved bonding ability, Excellent mechanical properties, reduced wall thickness and weight

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

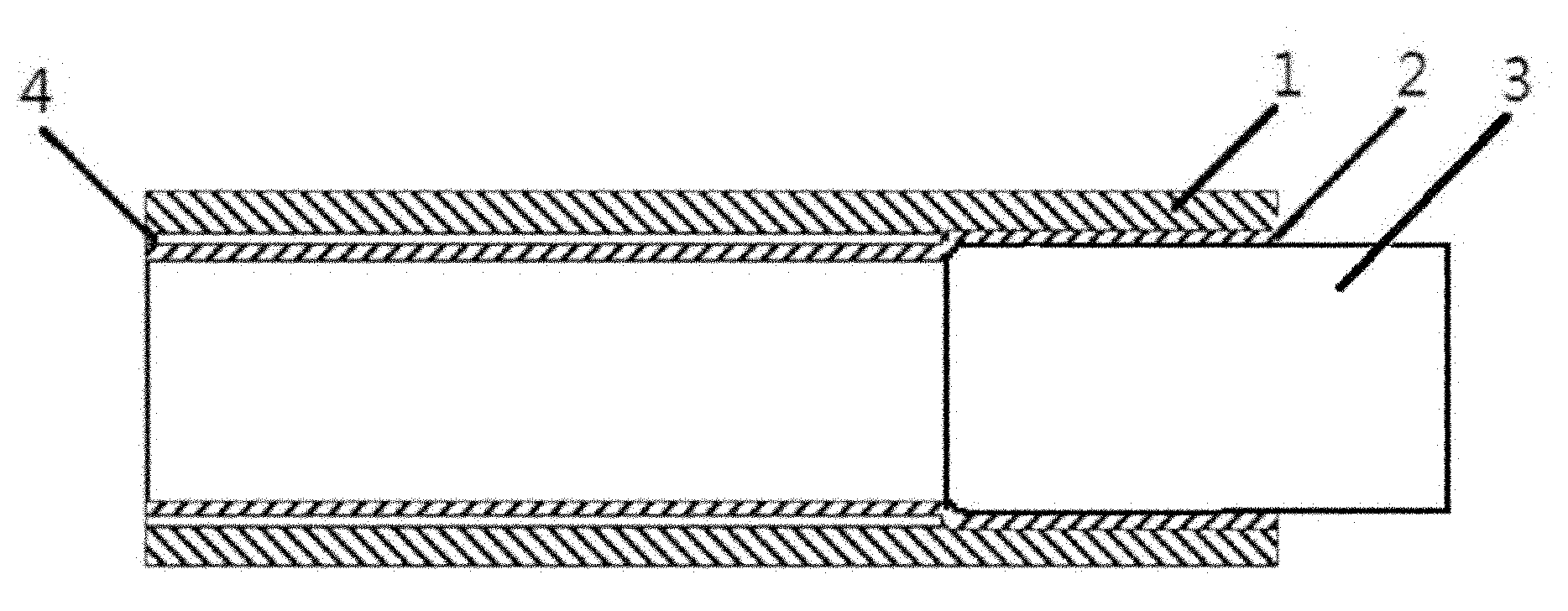

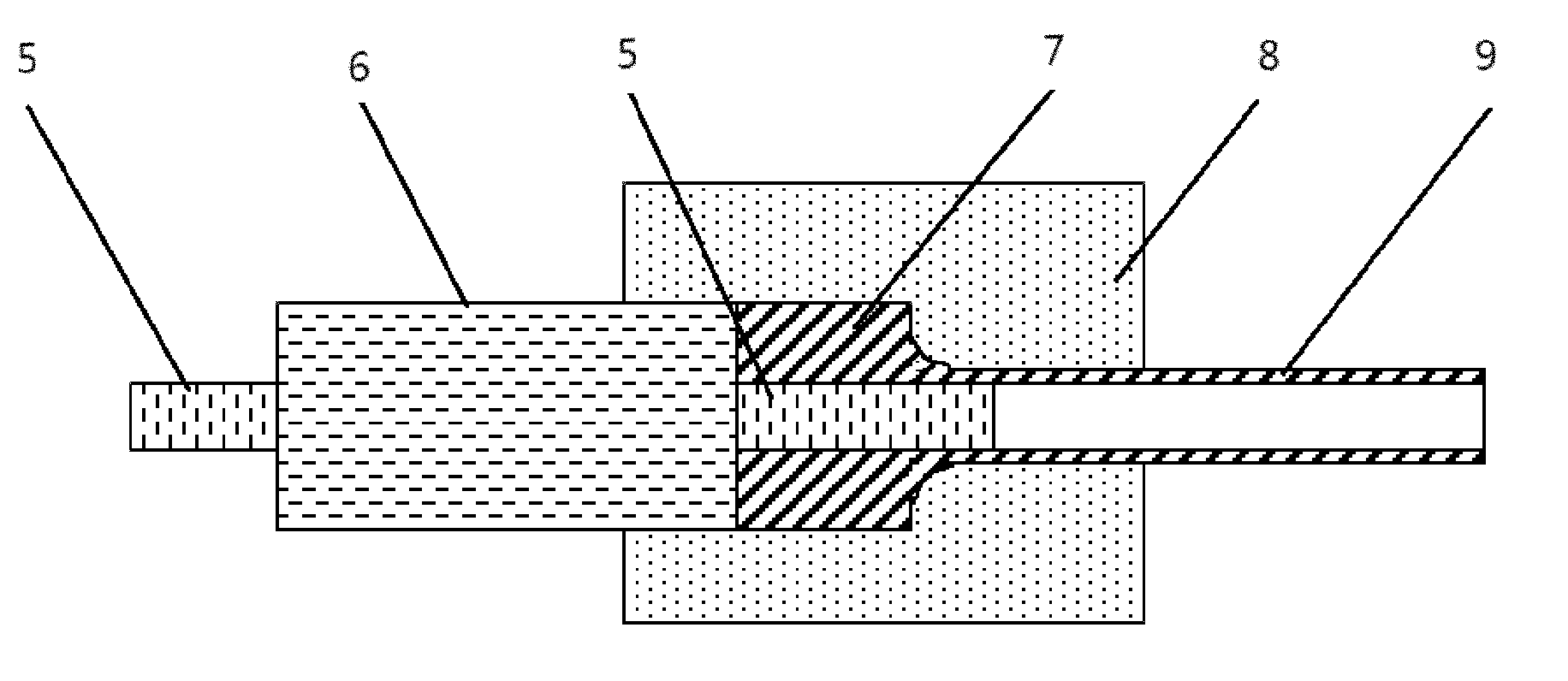

[0022] 1. Preparation of composite tube blank

[0023] Such as figure 1 As shown, the corrosion-resistant superalloy inner tube blank 2 is first placed into the pipeline steel outer tube blank 1, and the corrosion-resistant superalloy inner tube blank 2 and the pipeline steel outer tube blank 1 form an inner tube blank and an outer tube blank before composite Gap 4, extending through the rolling mandrel 3 to the corrosion-resistant superalloy inner tube blank 2 for rotary extrusion (the rolling mandrel rotation speed is 20-250 rpm), to realize the corrosion-resistant superalloy inner tube blank of the composite tube blank 2 Plastic deformation, pipeline steel outer tube blank 1 Elastic deformation, so that the outer tube of the composite tube blank produces a state of compressive stress on the inner tube, so as to achieve a close physical combination of the inner wall of the outer tube of the composite tube blank and the outer wall of the inner tube of the composite tube blank...

Embodiment 1

[0033] Put the Inconel625 corrosion-resistant superalloy inner tube blank with an inner diameter of Φ134.4mm and a wall thickness of 15.1mm into an L450 pipeline steel outer tube blank with an inner diameter of Φ165mm and a wall thickness of 90mm, and squeeze it through the rolling mandrel rotation (rolling mandrel rotation The speed is 60 rpm), and the inner diameter of the corrosion-resistant superalloy inner tube is plastically deformed to Φ135mm, and the pipeline steel outer tube is elastically deformed to achieve the corrosion-resistant superalloy of the inner wall of the pipeline steel outer tube and the composite tube. The tight fit of the outer wall of the inner tube blank.

[0034] Under the protection of the glass protective coating, the composite tube blank is heated to 1200°C at a heating rate of 15°C / min, and kept for 40 minutes, and then the preheated composite tube blank is put into a hot extrusion machine and extruded The ratio is 10:1, the extrusion speed is 5...

Embodiment 2

[0036] Put the Inconel825 corrosion-resistant superalloy inner tube blank with an inner diameter of Φ99.4mm and a wall thickness of 10.1mm into an L450 pipeline steel outer tube blank with an inner diameter of Φ120mm and a wall thickness of 60mm, and squeeze it through the rolling mandrel rotation (rolling mandrel rotation The speed is 80 rpm), and the inner diameter of the corrosion-resistant superalloy inner tube is plastically deformed to Φ100mm, and the outer tube is elastically deformed to achieve the inner wall of the pipeline steel outer tube of the composite tube and the corrosion-resistant superalloy inner tube of the composite tube. Tight fit of the outer wall.

[0037] Under the protection of the glass protective coating, the composite tube blank is heated to 1180°C at a heating rate of 10°C / min, and kept for 40 minutes, and then the preheated composite tube blank is put into a hot extrusion machine and extruded The ratio is 5:1, the extrusion speed is 80mm / s, and t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com