Method for preparing camellia oil instant noodle

A technology of camellia oil and instant noodles, applied in the field of food processing, can solve problems such as different physical and chemical properties, and achieve the effects of long storage shelf life, reduced oil loss, and golden complexion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] Embodiment 1 Technology test of camellia oil fried instant noodles

[0030] (1) Raw materials:

[0031] Using high-gluten wheat flour as the main raw material, the cooked noodles are obtained by adding appropriate amount of water to prepare dough, ripening, rolling, cutting into strips, steaming, cutting and folding. Can refer to the preparation method of existing instant noodle cake.

[0032] The camellia oil is purchased from a supermarket. In this embodiment, the first-stage pressed camellia oil is used, and the brand is not limited.

[0033] (2) Experimental method:

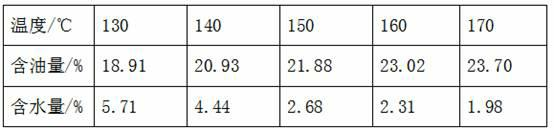

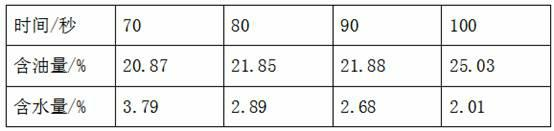

[0034] ① Effect of different frying temperatures on the quality indexes of instant noodles

[0035] Take 100 grams of cooked noodles, add them into camellia oil at different temperatures and fry them for 90 seconds for testing and evaluation. In order to illustrate the design concept of the present invention, this example selectively gives the experimental results of frying in camellia oil at 130°...

Embodiment 2

[0044] Embodiment 2 Contrast test of camellia oil and palm oil fried instant noodles

[0045] (1) Experimental materials: the same as in Example 1.

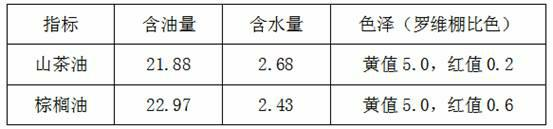

[0046] (2) Test method: Take two portions of 100 grams of steamed noodles, add them to camellia oil and palm oil at a temperature of 150°C, and fry for 90 seconds. The amount of camellia oil and palm oil is the same, and they can be completely soaked Noodle cake, and 1.5 centimeters higher than the surface of the noodle cake, take out the noodle cake, after draining the oil and cooling, take a sample to detect the color, oil content and water content of the instant noodles, the results are shown in Table 3:

[0047] Table 3 Comparison of quality indexes between camellia oil and palm oil fried instant noodles

[0048]

[0049] It can be seen from Table 3 that the instant noodles fried with camellia oil have low oil content and meet the requirements of water content, which can ensure good storage performance and long shelf life o...

Embodiment 3

[0050] Embodiment 3 Comparison test of storage of instant noodles fried with camellia oil and palm oil

[0051] (1) Test material: same as Example 1.

[0052] (2) Test method: Take two portions of 500 grams of cooked noodles, add them to camellia oil and palm oil at a temperature of 150°C, and fry for 90 seconds. The amount of camellia oil and palm oil is the same, and they can completely soak the noodles , and 1.5 centimeters higher than the surface of the dough cake, take out the dough cake, drain the oil, and cool down to prepare fried instant noodles. Take several portions of 50 grams of instant noodles fried with camellia oil and palm oil, seal them and store them at room temperature. Take regular samples to test the acid value, POV value, and rehydration time of instant noodles. The results are shown in Table 4.

[0053] Table 4 Storage quality of instant noodles fried with camellia oil and palm oil

[0054]

[0055] It can be seen from Table 4 that the instant nood...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com