Solid electrode of self-consumption fuel generating device

A solid electrode and fuel power generation technology, which is applied to fuel cell parts, battery electrodes, fuel cell half-cells and primary battery half-cells, etc., can solve problems such as high cost, environmental pollution, and large investment. Achieve the effect of low cost, good safety performance and good working characteristics

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

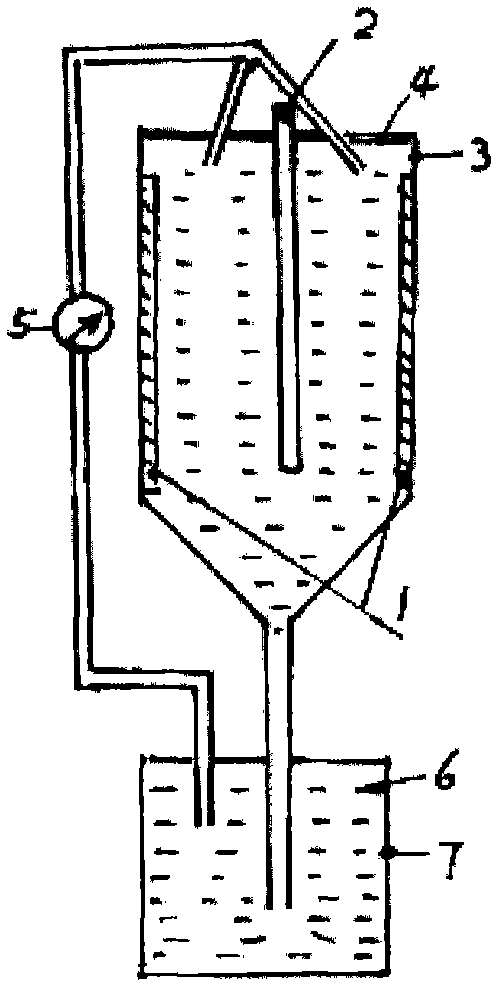

[0062] Example 1: The negative plate is composed of bismuth 0.6% + tin 3% + gallium 0.21% + magnesium 1.5% + zinc 0.8% + aluminum 91.04% + cerium 0.7% + lanthanum 0.15% + praseodymium 2%, after smelting, it is processed into the Plates of required thickness are cut into pieces of required size and installed on the cover of the power generation unit. One piece is used and is a consumable part. The positive plate is composed of stainless steel mesh + phosphorus graphite 5% + soil graphite 15% + wood carbon 10% + acetylene carbon powder 19% + manganese oxide 35% + LD0020 16%, etc., and is molded, with an area of 576cm 2 (The area can be increased or decreased according to the requirements of the amount of power generation), inlaid on the housing of the power generation unit device, two pieces are used for long-term use.

[0063] In the power generation unit device, add a conductive medium (neutral, containing calcium ions, sodium ions, potassium ions and magnesium ions), instal...

Embodiment 2

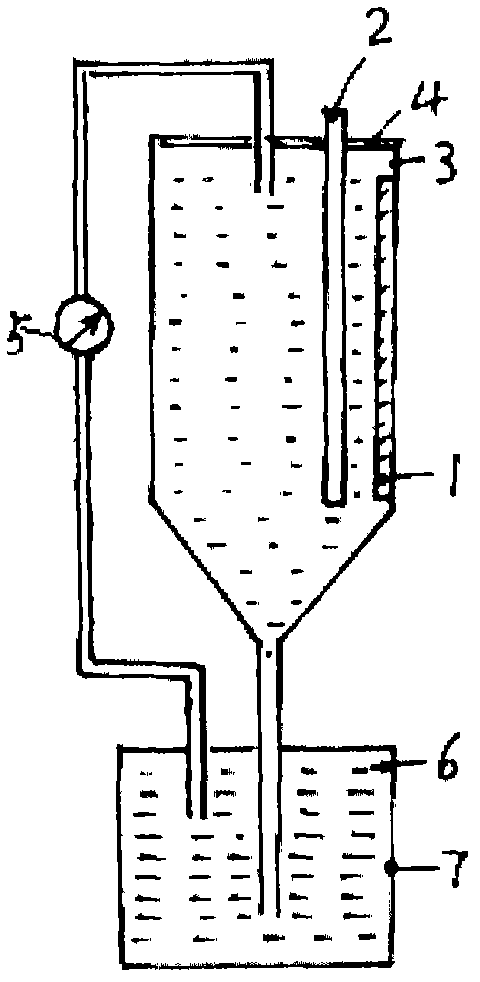

[0064] Example 2: The negative plate is composed of bismuth 1.5% + tin 0.8% + gallium 2.0% + magnesium 3.5% + zinc 1.6% + aluminum 87.6% + cerium 1.9% + lanthanum 1.1%, after smelting, it is processed into a plate of required thickness , cut into pieces of the required size, installed on the cover of the power generation unit device, one piece is used, it is a consumable part. The positive plate is composed of copper mesh + phosphorus graphite 10% + soil graphite 20% + wood carbon 4% + acetylene carbon powder 21% + manganese oxide 25% + PE5% + polytetrafluoroethylene 15%, etc., after molding, the area is 576cm 2 (The area can be increased or decreased according to the requirements of the power generation), inlaid on the housing of the power generation unit device, and used in one piece for long-term use.

[0065] In the power generation unit device, add a conductive medium (neutral, containing calcium ions, sodium ions, potassium ions and magnesium ions), install a circulation...

Embodiment 3

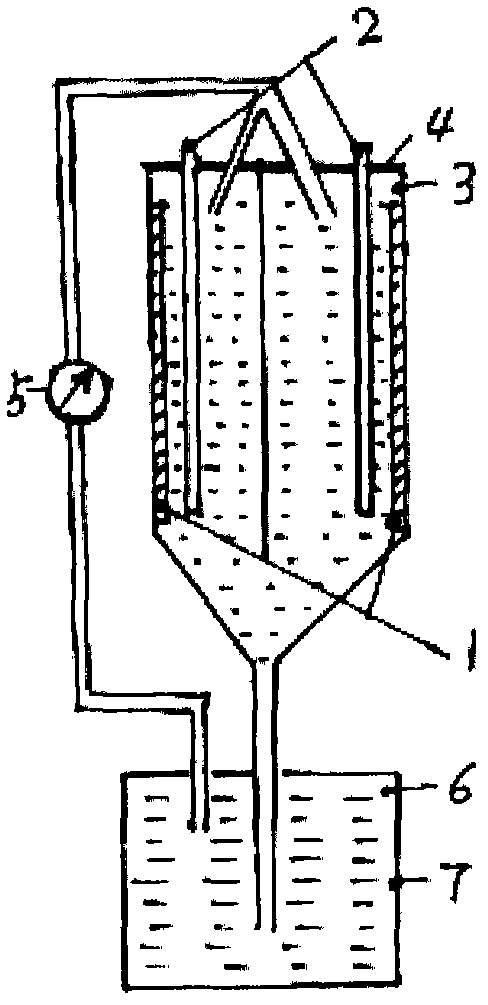

[0066] Example 3: The negative plate is composed of bismuth 3.5%+tin 1.5%+gallium 2.5%+magnesium 2.5%+zinc 6.5%+aluminum 81.2%+lanthanum 2.3%, after smelting, it is processed into plates of required thickness and cut into the desired thickness The block of the required size is installed on the cover of the power generation unit, and two blocks are used, which are consumable parts. The positive plate is composed of iron mesh + phosphorus graphite 15% + soil graphite 10% + wood carbon 20% + acetylene carbon powder 5% + manganese oxide 40% + polytetrafluoroethylene 10%, etc., and is molded, with an area of 576cm 2 (The area can be increased or decreased according to the requirements of the amount of power generation), inlaid on the housing of the power generation unit device, two pieces are used for long-term use.

[0067] In the power generation unit device, add a conductive medium (neutral, containing calcium ions, sodium ions, potassium ions and magnesium ions), install a ci...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com