Method for synthesizing lithium iron phosphate and carbon nanotube composite material in situ

A technology of lithium iron phosphate and carbon nanotubes, which is applied in the direction of electrical components, battery electrodes, circuits, etc., can solve the problems of high price and high cost, and achieve the effects of uniform distribution, flat discharge platform, and lower volume resistivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] a) Weigh 98.4g Fe-- -- PO-- 4 , 25.4gLi 2 CO 3 , 15.4g of glucose, 0.37g of ferrocene were milled for 3h in a ball mill jar with alcohol as the milling medium;

[0021] b) Pump the stirred mixed slurry into a clean container, place it in a drying oven, and control the temperature of the drying oven to 70°C. After the alcohol is completely evaporated, the obtained solid powder is milled with a ball mill jar for 2 hours;

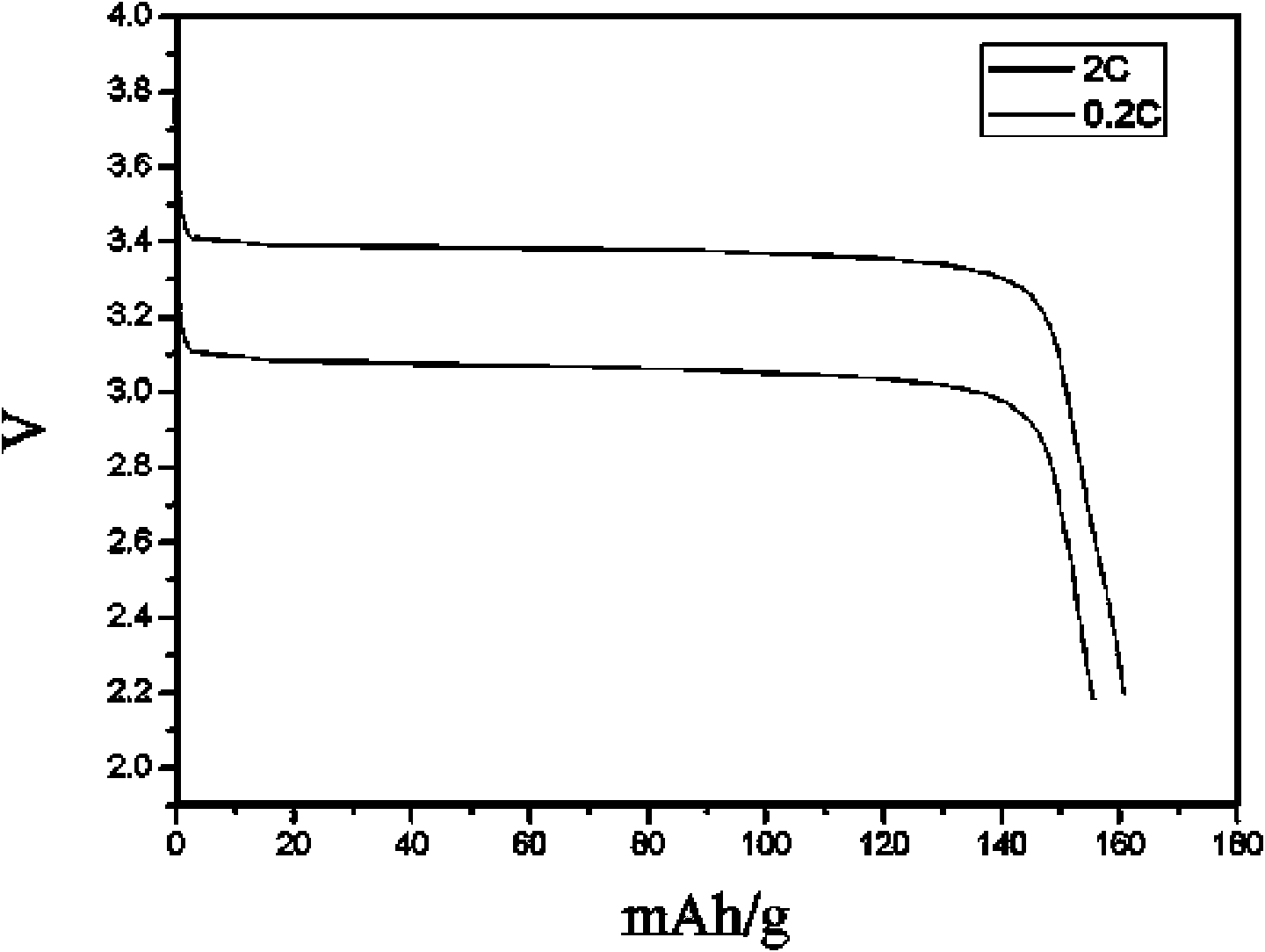

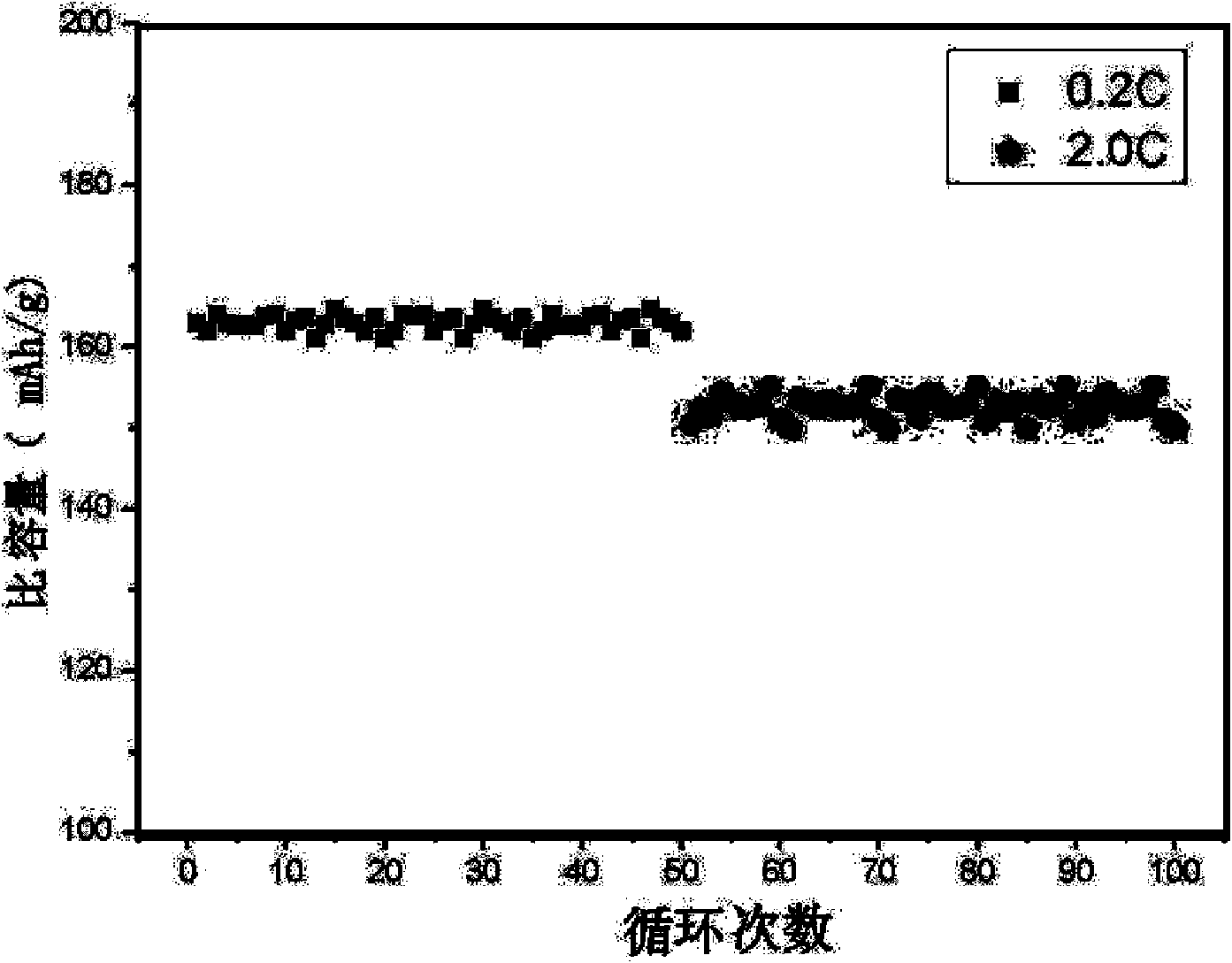

[0022] c) The dry material after ball milling is kept at 180°C for 1 hour in a nitrogen atmosphere, then heated to 400°C and held for 2.5 hours, then the nitrogen flow is replaced by a mixed flow of nitrogen and benzene steam, and the flow rate of the stupid steam is controlled at 2.5ml / min Afterwards, the temperature was raised to 820° C. for sintering for 9 hours to obtain a composite material of carbon nanotubes and lithium iron phosphate. The 0.2C discharge capacity is 162mAh / g, and the 2C discharge capacity is 150mAh / g.

Embodiment 2

[0024] a) Weigh 54.7g FeC 2 o 2 2H 2 O, 11.7gLi 2 CO 3 , 34.51gNH 4 ·H 2 PO 4 , 7.2g sucrose and 0.17g ferrocene were milled in a ball mill tank with alcohol as the milling medium for 4h;

[0025] b) Pump the stirred mixed slurry into a clean container, place it in a drying oven, and control the temperature of the drying oven to 70°C. After the alcohol is completely evaporated, the obtained solid powder is milled with a ball mill jar for 2 hours;

[0026] c) The dry material after ball milling is kept at 200°C for 1.5h in a nitrogen atmosphere, then heated up to 420°C and held for 2h, then the nitrogen flow is replaced by a mixed flow of nitrogen and benzene steam, and the flow of stupid steam is controlled at 15ml / min. , the temperature was programmed to 830° C. for sintering for 11 hours, and the composite material of carbon nanotubes and lithium iron phosphate was obtained.

Embodiment 3

[0028] a) Weigh 54.7g FeC 2 o 2 2H 2 O, 7.2gLiOH, 34.1gNH 4 ·H 2 PO 4 , 7.53g of maleic acid and 0.16g of ferrocene were milled for 4h in a ball milling tank with acetone as the milling medium;

[0029] b) Pump the mixed slurry after ball milling into a clean container, place it in a drying oven, and control the temperature of the drying oven to 70°C. After the alcohol is completely evaporated, the obtained solid powder is milled with a ball mill jar for 2.5 hours;

[0030] c) The dry material after ball milling is kept at 200°C for 2 hours in a nitrogen atmosphere, then heated to 420°C and kept for 2 hours, then the nitrogen flow is replaced by a mixed flow of nitrogen and benzene steam, and the flow of toluene steam is controlled at 8ml / min. The temperature was programmed to rise to 840° C. for sintering for 11 hours to obtain a composite material of carbon nanotubes and lithium iron phosphate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| boiling point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com