Back electrode strap for thin film solar cell and producing method of thin film solar cell

A technology for solar cells and back electrodes, which is applied in the direction of final product manufacturing, sustainable manufacturing/processing, circuits, etc., can solve the problems of increasing the number of manufacturing processes of thin-film solar cells, and achieve simplification of manufacturing processes, efficiency of manufacturing processes, The effect of easy manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

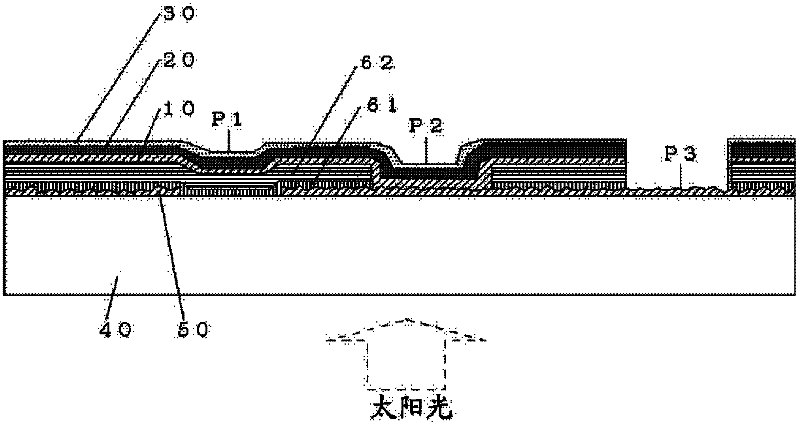

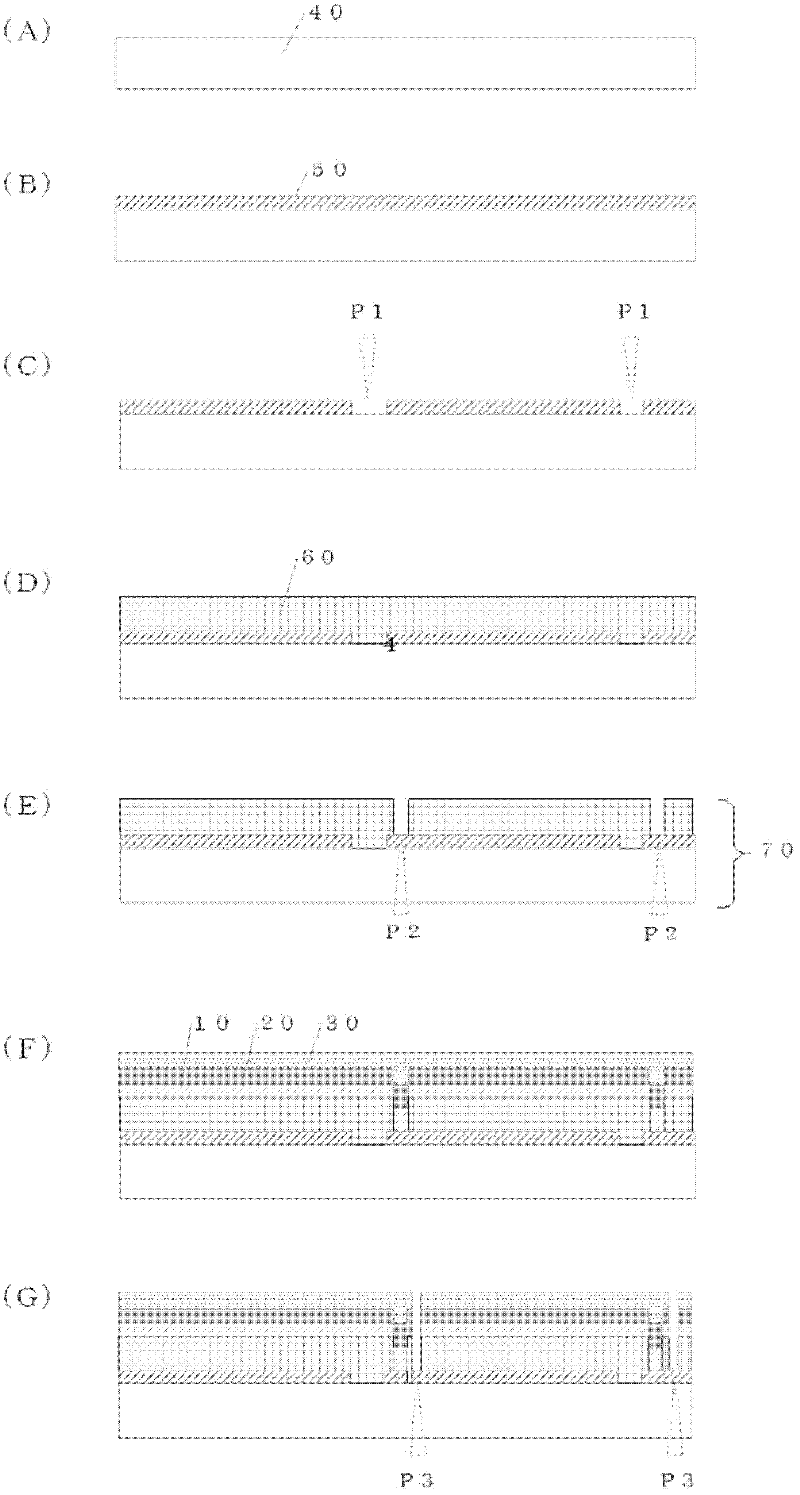

[0127] use figure 2 (A)~(E) explain the method of manufacturing the adherend, and use it in the subsequent steps Figure 5 Be explained. First, like figure 2 As shown in (B), the transparent substrate 40 prepares a glass plate with a length of 10 cm square and a thickness of 4 mm, and SnO is used as the transparent conductive film 50 2 . At this time, the film thickness of the transparent conductive film 50 is 800 nm, the sheet resistance is 10 Ω / □, and the haze is 15 to 20%.

[0128] Then, like figure 2 As shown in (C), an amorphous silicon layer 61 is formed with a thickness of 300 nm from the transparent conductive film 50 processed to the laser scribing P1 by the plasma CVD method, and then the amorphous silicon layer 61 is deposited by the plasma CVD method A microcrystalline silicon layer 62 is formed with a thickness of 1.7 μm, thereby forming figure 2 The silicon-based photoelectric conversion layer 60 shown in (D). Such as figure 2 As shown in (E), the photoelectr...

Embodiment 2~23

[0133] Except for setting the conditions shown in Table 1, the test was performed in the same manner as in Example 1. Here, the silica sol-gel used in Example 2 and the like used SB-10A manufactured by Mitsubishi MATERIAL. In addition, the reflective electrode film composition used in the wet coating method of Example 12 and the like was produced as follows.

[0134] First, silver nitrate is dissolved in deionized water to prepare a metal ion aqueous solution. Then, sodium citrate was dissolved in deionized water to prepare an aqueous sodium citrate solution having a concentration of 26% by mass. In a nitrogen gas stream maintained at 35°C, granular ferrous sulfate was directly added to the sodium citrate aqueous solution and dissolved to prepare a reducing agent aqueous solution containing citrate ions and ferrous ions in a molar ratio of 3:2. Next, while maintaining the above-mentioned nitrogen gas flow at 35°C, the stir bar of the magnetic stirrer was put into the reducing a...

Embodiment 24

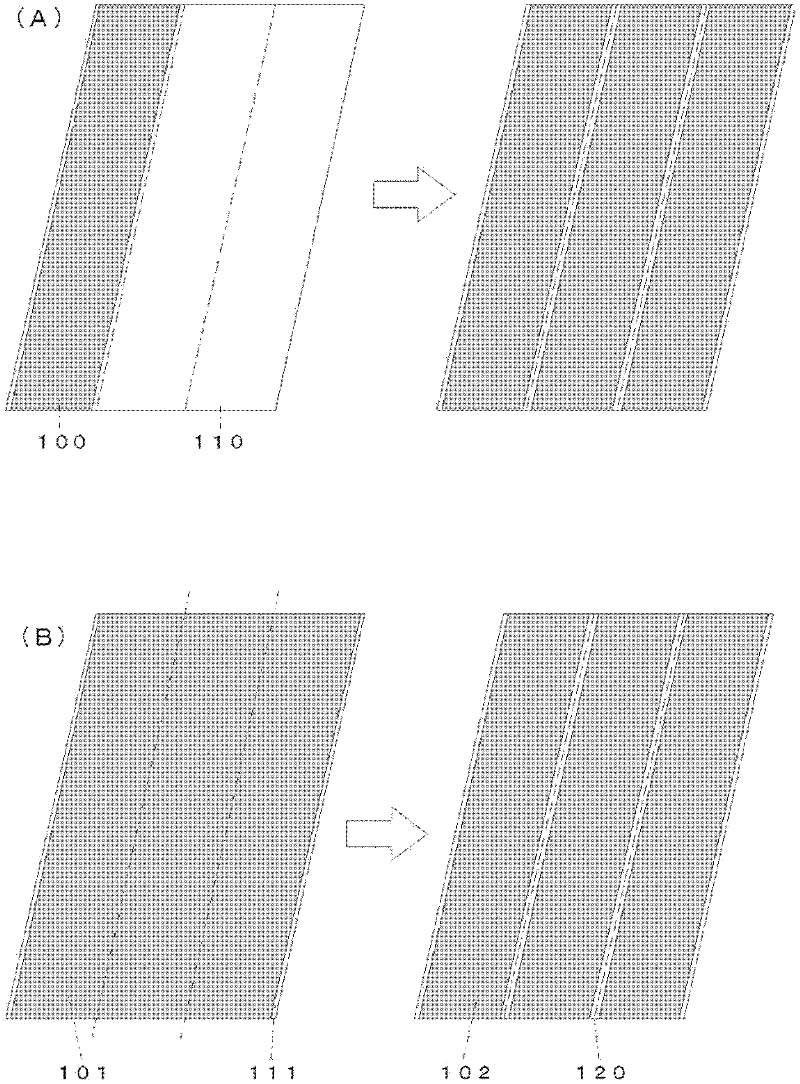

[0139] use Figure 5 Be explained. Figure 5 As for the adherend 7 shown in (a), the adherend produced in Example 1 was used. Next, a carrier tape 8a made of polyethylene terephthalate (PET) was coated with a silica sol-gel as a barrier film 3a so that the film thickness after heat treatment became 1 μm using a mold coating device, and Heat treatment at 120°C for 10 minutes. On this basis, an 800 nm Ag film was formed by sputtering as the reflective electrode film 2a.

[0140] Next, the transparent electrode film composition used when forming the transparent electrode film 1a is prepared as follows. As the conductive fine particles, 50 parts by mass of AZO powder having an atomic ratio of Al / (Al+Zn)=0.02 and a particle size of 0.03 μm was added, and IPA was added as a dispersion medium to make the entirety 100 parts by mass. A horizontal mill (horizontal bead mill) was operated on the mixture using zirconia beads with a diameter of 0.3 mm for 2 hours to disperse the fine part...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com