Sheet Fasteners

A technology of fasteners and sheets, applied in fasteners, sliding fastener components, clothing, etc., can solve problems such as gaps, ineffectiveness, and non-sheet fasteners

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0056] Next, specific embodiments of the present invention will be described with reference to the drawings.

[0057] [the whole frame]

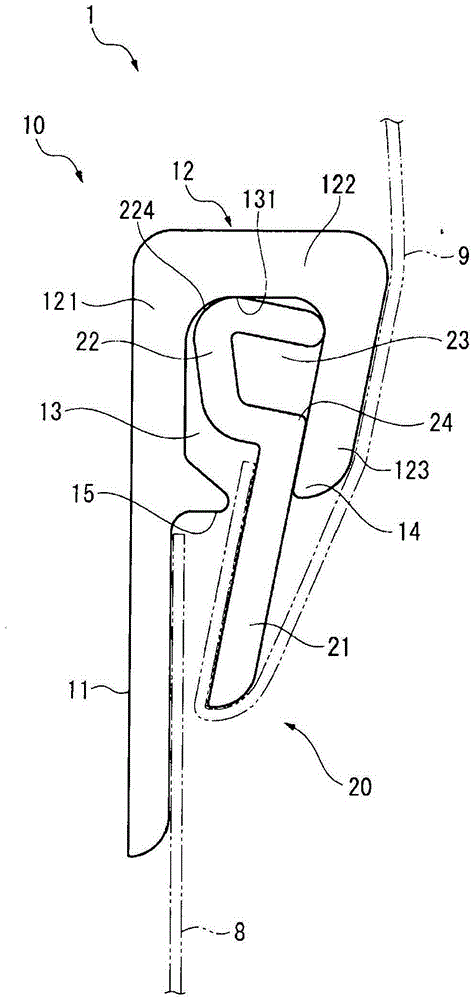

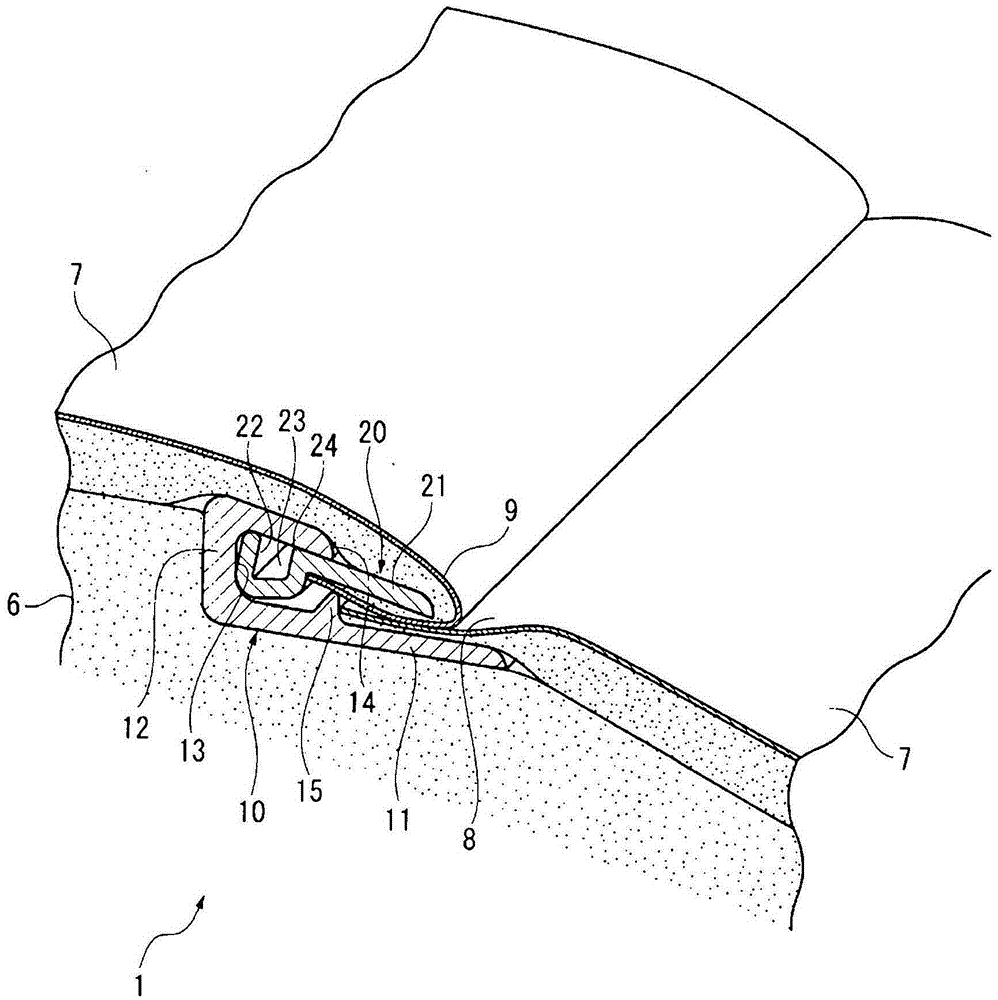

[0058] figure 1 Among them, the sheet fastener 1 of this embodiment is a member that continuously fastens a pair of sheet edges 8, 9 at the seam when the sheet 7 of the skin member is laid on the surface of the cushioning member 6, and has The first member 10 and the second member 20 are integrally molded from a synthetic resin material as continuous members having a constant cross-sectional shape.

[0059] The first member 10 and the second member 20 are each formed as a continuous member manufactured by extrusion molding, injection molding, or the like of a synthetic resin material.

[0060] [Part 1]

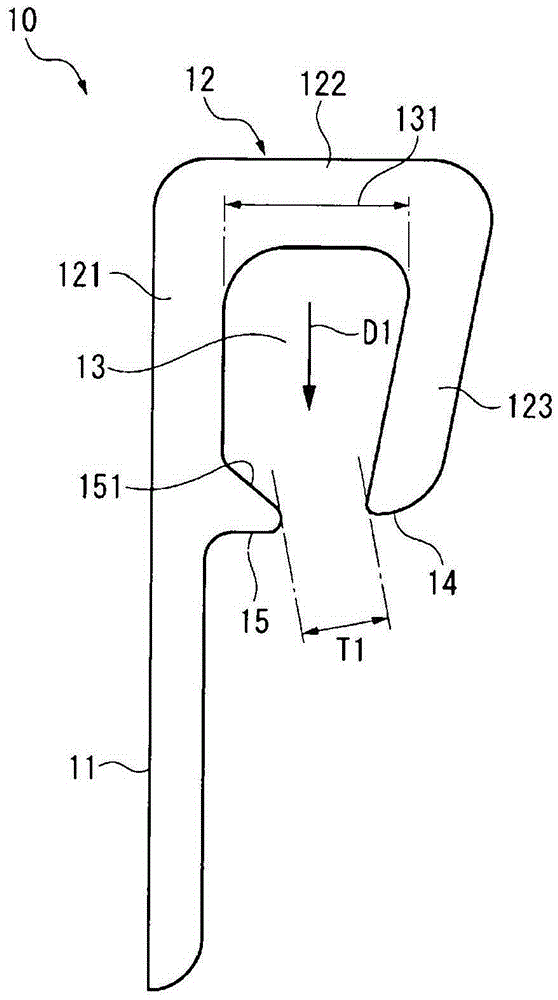

[0061] figure 2 The cross-sectional shape of the first member 10 of this embodiment is shown in .

[0062] The first member 10 includes a first fixing portion 11 for fixing the sheet edge 8, a holding portion 12 continuous with one end...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com