Coaxial connector with switch

A technology of coaxial connectors and switches, applied in the direction of connection, fixed connection, bipolar connection, etc., can solve problems such as cost increase, troublesome ground wire fixing, parts processing costs, assembly costs and other productivity degradation, and achieve higher processing costs , cost reduction, miniaturization effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

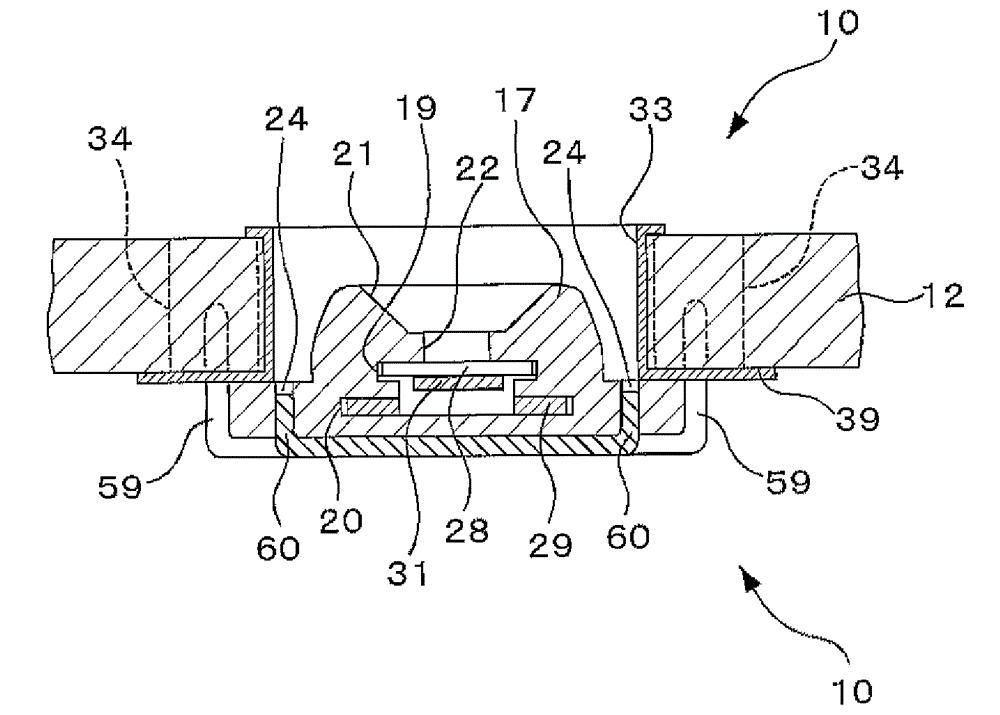

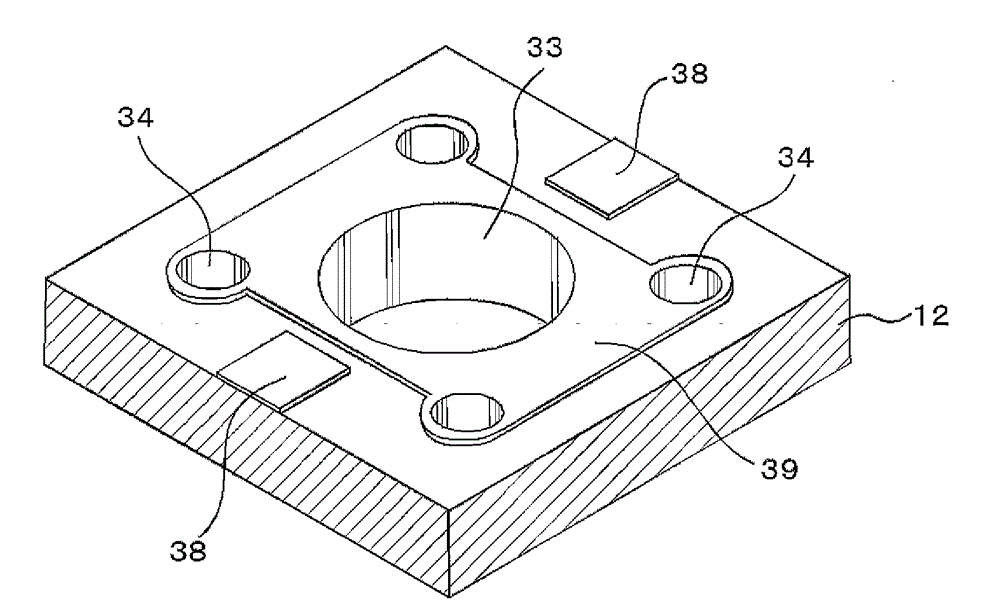

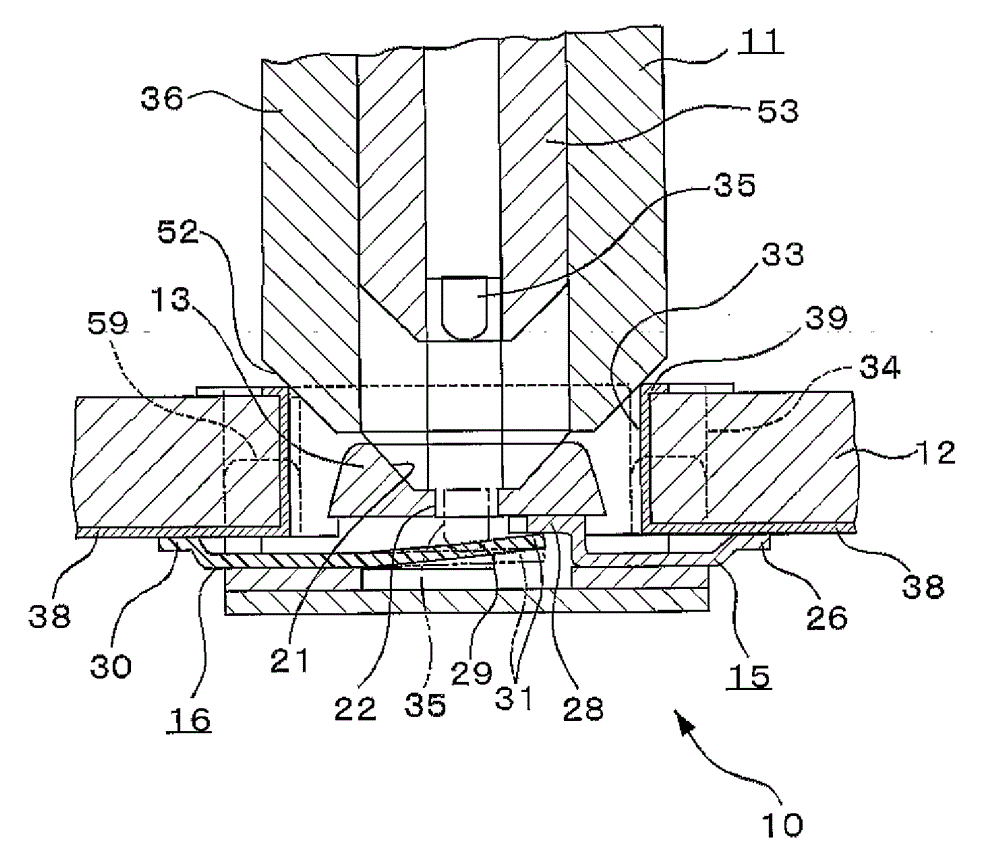

[0044] based on Figure 1 to Figure 5 Example 1 of the present invention will be described.

[0045] exist Figure 4 Among them, the coaxial connector 10 with a switch of the present invention is composed of a housing 13 made of an insulating material such as a plastic material, an outer cover 14 formed by pressing a conductive metal plate, and a switch mechanism. The housing 13 is The upper part is in the shape of a cone for guiding the probe 11, and the lower part is in the shape of a quadrangular plate. The overall height is as low as possible. A terminal, specifically a normally closed terminal 15 and a common terminal 16.

[0046] The coaxial connector with switch 10 of the present invention is fitted and fixed on the printed circuit board 12 from the lower surface.

[0047] Above-mentioned casing 13 is made up of the guide cylinder part 17 that overall height is lower than above-mentioned printed circuit board 12 in the upper half, and the substrate part 18 of quadril...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com