Device and method for preparing tetravalent uranium by dynamic membrane electrolysis

A technology of tetravalent uranium and dynamic membrane, which is applied in the direction of electrolysis process, electrolysis components, electrode shape/type, etc., can solve the problems of long electrolysis time, undisclosed tetravalent uranium reduction rate, device diagram, and low current density, etc., to achieve Low oxygen overpotential, good mechanical strength, and low resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

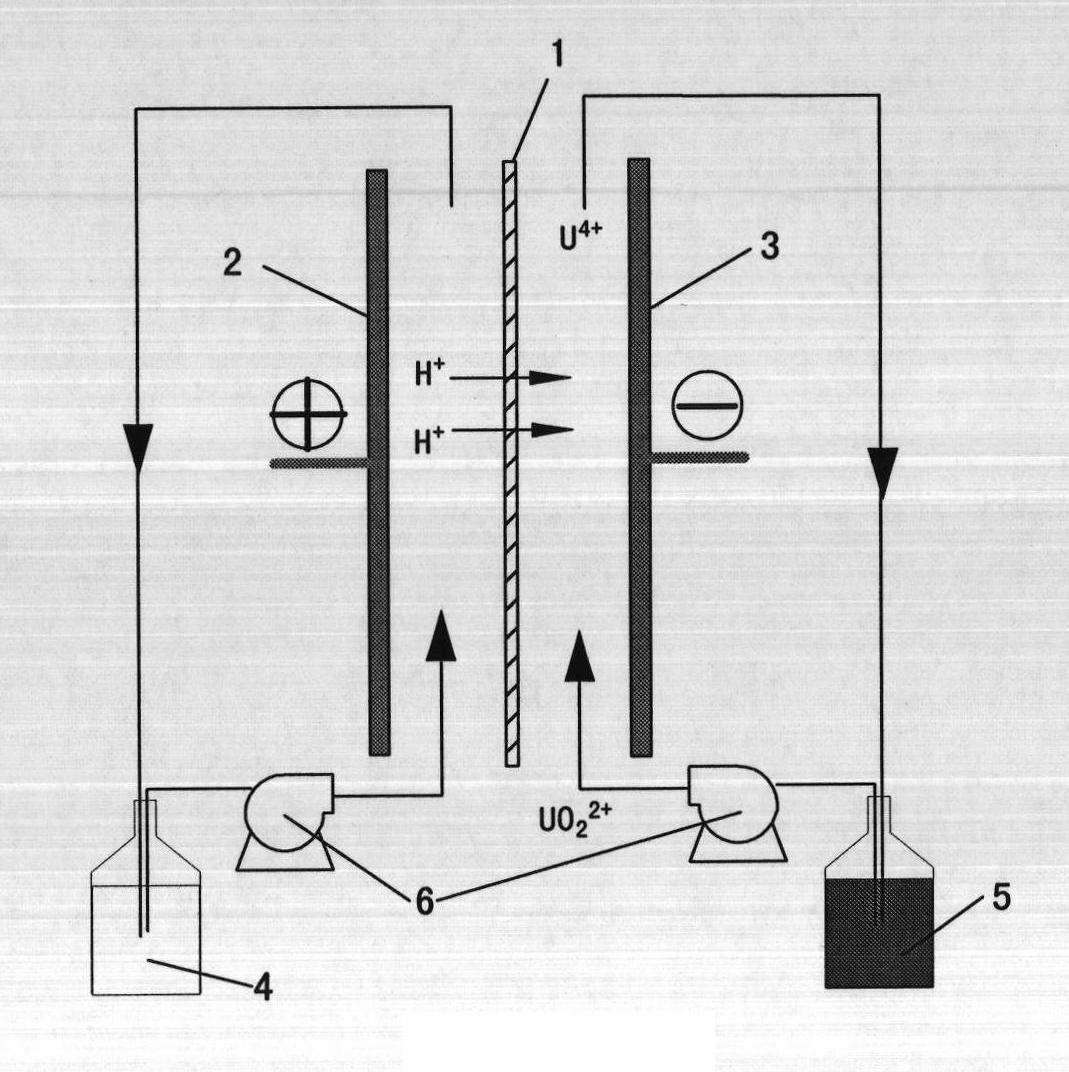

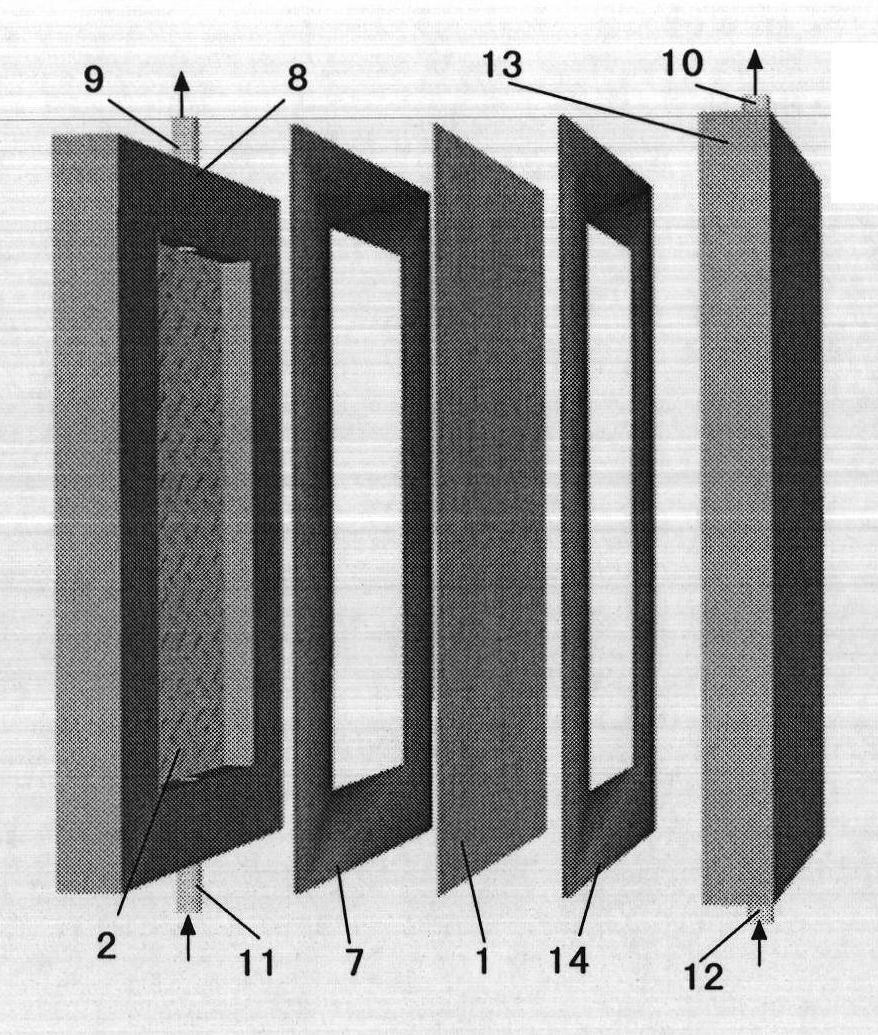

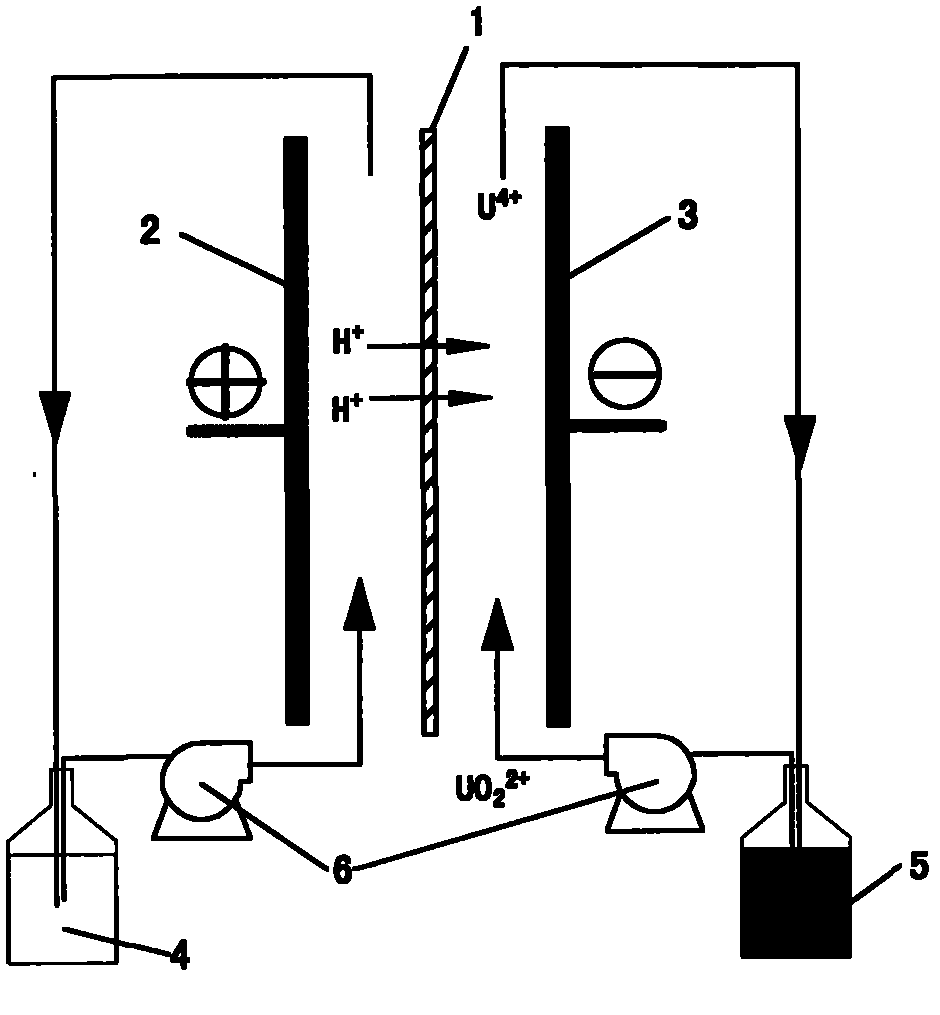

[0021] Such as figure 1 with figure 2 As shown, a device for preparing tetravalent uranium by dynamic membrane electrolysis, the device consists of cation exchange membrane (1), anode (2), cathode (3), anolyte (4), catholyte (5), peristaltic pump ( 6), gasket a (7), electrode frame a (8), anolyte outlet (9), catholyte outlet (10), anolyte inlet (11), catholyte inlet (12), electrode frame b (13 ), gasket b (14), wherein, from left to right, the device is electrode frame a (8), gasket a (7), cation exchange membrane (1), gasket b (14), electrode frame b(13), they form a sealed space layer by layer; liner a(7) and liner b(14) are quadrilateral structures; electrode frame a(8) is a hollow frame structure, and electrode frame a(8) ) is equipped with an anode (2), an anolyte inlet (11) is left at the lower end of the electrode frame a (8), and an anolyte outlet (9) is left at the upper end of the electrode frame a (8); the electrode frame b ( 13) is a hollow frame structure, a c...

Embodiment 2

[0027] The device of Example 1 was used, wherein the distance between the cathode and the anode was 10 mm.

[0028] The composition of catholyte is: uranyl nitrate 197g / L, nitric acid 4.1mol / L, hydrazine 0.18mol / L; anolyte is 2.5mol / L nitric acid solution. The catholyte of 500ml and the anolyte of 500ml are both circulated at a flow rate of 300ml / min under the delivery of the peristaltic pump. Apply a current of 7.20A (100mA / cm 2 ), after 4.5 hours of electrolysis, the tetravalent uranium content in the catholyte reached 96%, the nitric acid concentration was 2.1mol / L, the hydrazine concentration was 0.062mol / L, and the feed liquid temperature was 38°C (room temperature 33°C).

Embodiment 3

[0030] The device of Example 1 was used, wherein the distance between the cathode and the anode was 15 mm.

[0031] The composition of catholyte is: uranyl nitrate 199g / L, nitric acid 2.2mol / L, hydrazine 0.52mol / L; anolyte is 2.5mol / L nitric acid solution. The catholyte of 500ml and the anolyte of 500ml are both circulated at a flow rate of 400ml / min under the delivery of the peristaltic pump. Apply a current of 8.64A (120mA / cm 2 ), after 3 hours of electrolysis, the tetravalent uranium content in the catholyte reached 93.1%, the nitric acid concentration was 0.7mol / L, the hydrazine concentration was 0.3mol / L, and the feed liquid temperature was 42°C (room temperature 28°C).

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com