Waste liquor recovery device and method

一种废液回收、废液的技术,应用在化学仪器和方法、水/污泥/污水处理、水污染物等方向,能够解决浪费、分离出、增加回收处理废液周期等问题,达到提高回收效率、防止氧化、节省回收成本的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The waste liquid recovery device provided by the technical solution will be further described in detail below in conjunction with the accompanying drawings and multiple embodiments.

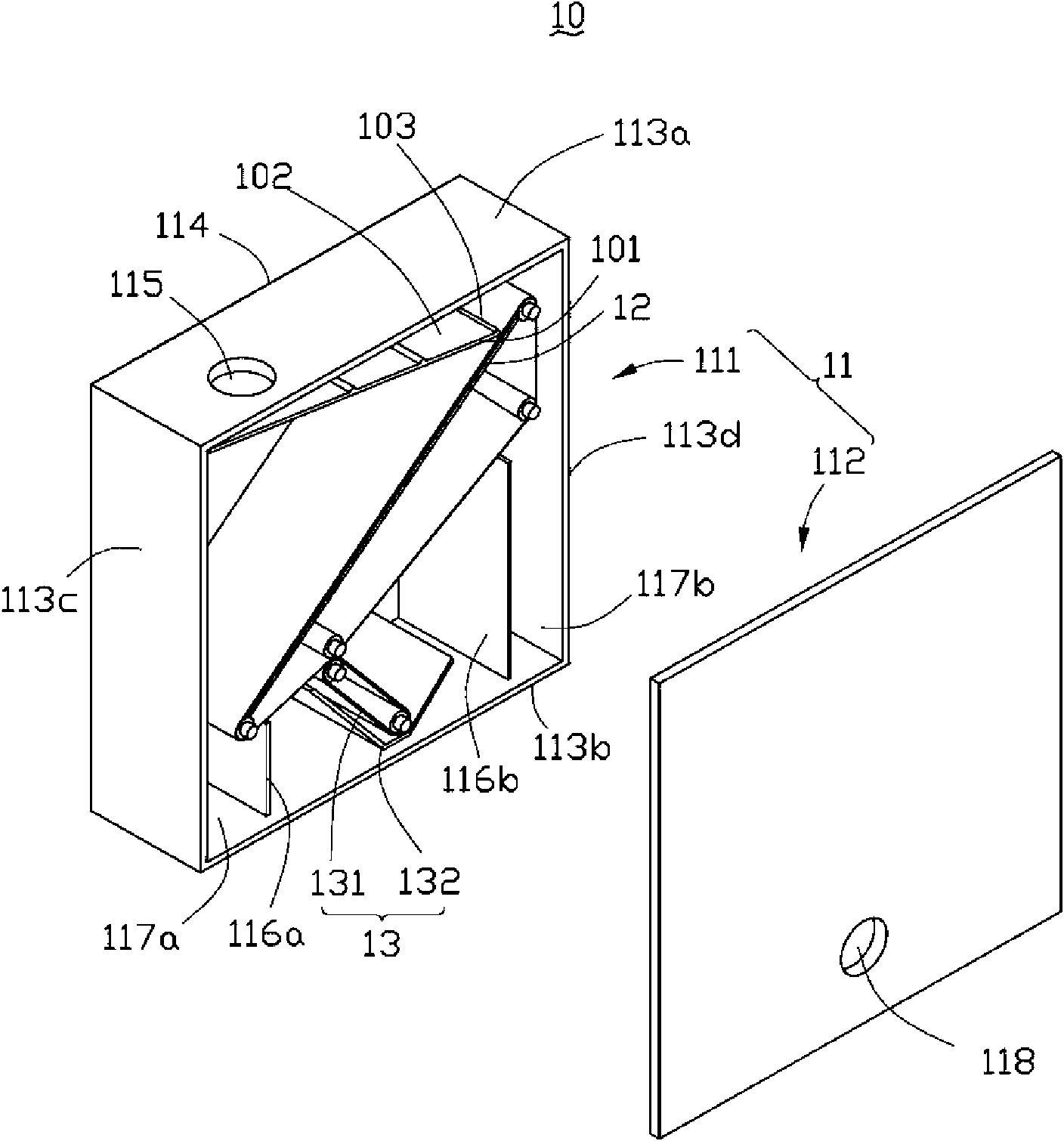

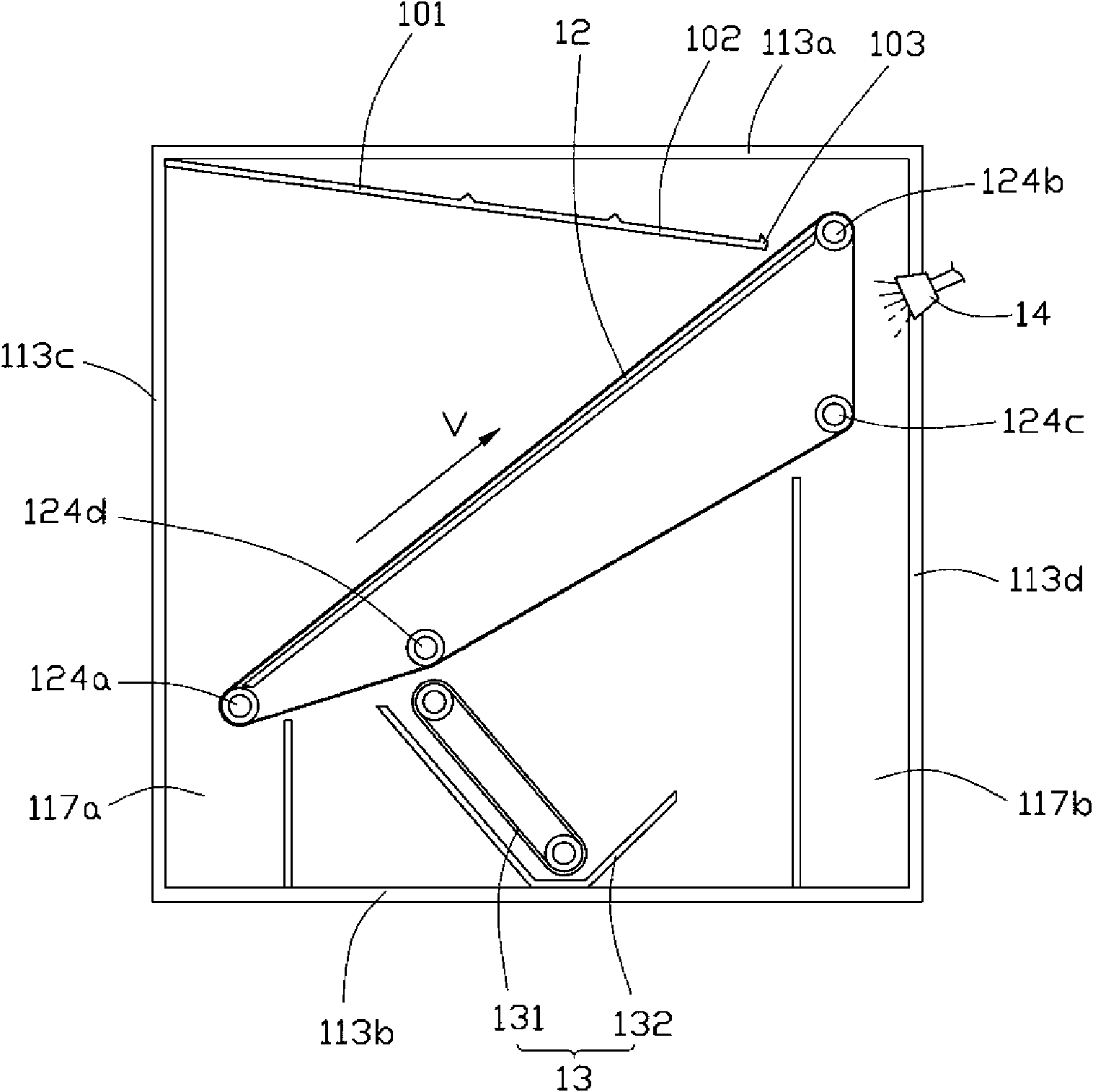

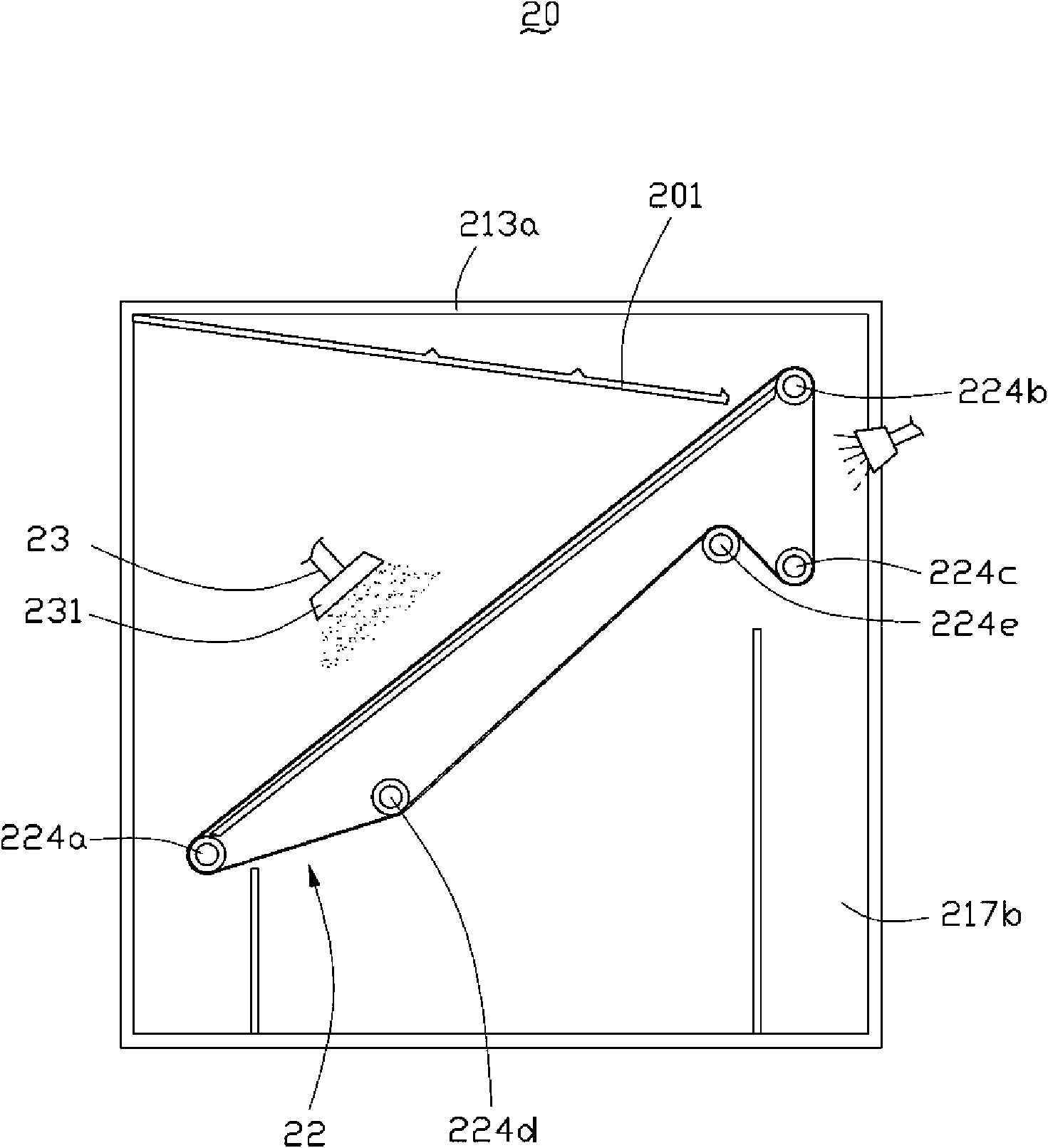

[0015] Please also refer to figure 1 and figure 2 The first embodiment of the technical solution provides a waste liquid recovery device 10 for recovering metal ions in waste liquid, which includes a frame 11, a waste liquid diversion device 101 housed in the frame 11, a conveyor belt 12 and a reducing agent Supply device 13.

[0016] The structure of the frame 11 can be designed according to actual needs. In this embodiment, the frame 11 includes a frame body 111 and a board body 112 .

[0017] The frame body 111 is used to fix the waste liquid diversion device 101 , the conveyor belt 12 and the reducing agent supply device 13 . In this embodiment, the frame body 111 has a top wall 113 a and a bottom wall 113 b opposite to each other, a first side wall 113 c and a second side wall 11...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com