Aging oil biodesulfurization microbial agent and method for treatment of aging oil with microbial agent

A biological desulfurization and aging oil technology, applied in the direction of microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of electrode and hanging plate damage, loss of desulfurization effect, easy adhesion of sulfide, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

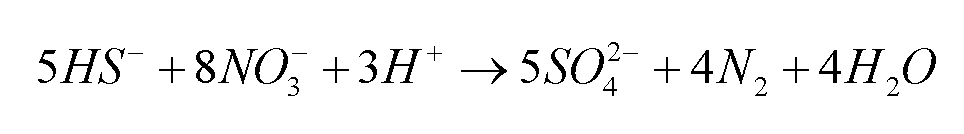

Method used

Image

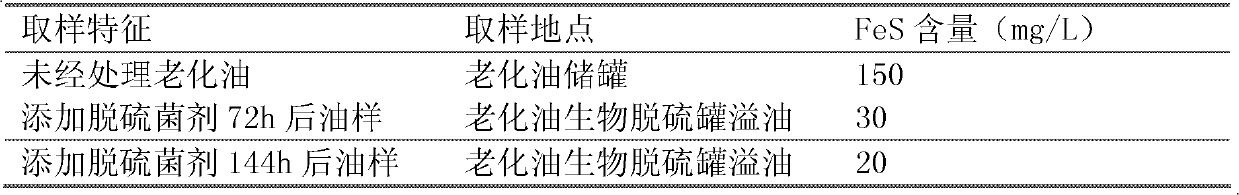

Examples

Embodiment 1

[0049] The water sample that will be taken from in the fish culture landscape pond is brought back to the laboratory and is used in aseptic room with 400mL enriched culture solution (in the purple sulfur bacteria seed culture medium, adding mass concentration is 2% Na 2 S·9H 2 O is the enrichment medium) into a 500mL Erlenmeyer flask, pour the collected water sample to the mouth of the bottle, airtight, oscillate and mix, and cultivate in a 37°C, 3000-5000lx light incubator for 10 days until cultured When the substance turns red, use a pipette gun to transfer 1mL of the enriched culture to another Erlenmeyer flask filled with fresh enriched culture solution. Repeat the above operation 2 to 3 times to obtain well-growing light and bacterial enrichment. Cultures. Then the enriched culture was diluted in a gradient, and then separated from the solid medium with agar added, and the colony was picked and cultured in the liquid medium (i.e. seed medium) for 7 days, and then repeate...

Embodiment 2

[0052] Soil samples collected from acidic (pH about 2 to 3) and moist soil (the sampling soil layer is 15cm away from the ground) were added to the Thiobacillus denitrifica seed medium in batches in a natural state, and the cultured soil samples were taken out after 3 weeks for separation nourish. Weigh 0.5g of the cultured soil sample, quickly pour it into a sterile water bottle with glass beads (the amount of glass beads should fill the bottom of the bottle is the best), shake for 5-10 minutes to fully break up the soil sample, which becomes 10 -2 soil suspension; use a sterile pipette to aspirate 10 -2 0.5mL of the soil suspension, put into 4.5mL sterile water and serve 10 -3 Dilution, so repeated, can make 10 -3 ~10 -8 After cultivation, take the turbid bacterial solution at the last level, dilute it in a gradient, and then separate it from the solid medium with agar added, pick but the colonies are cultured in the liquid medium for 7 days, and repeat the solid medium ...

Embodiment 3

[0055] The composition of the seed culture medium of purple sulfur bacteria PSE with the preservation number CCTCC NO: M2011276 is CH 3 COONa 3g / L, (NH 4 ) 2 SO 4 1.0g / L, MgSO 4 0.2g / L, NaCl 1g / L, KH 2 PO 4 0.3g / L, K 2 HPO 4 0.5g / L, CaCl 2 0.05g / L, yeast extract 0.1g, V B1 1Ml, 1L of distilled water, the isolated purple sulfur bacterium PSE with the preservation number CCTCC NO: M2011276 is cultured in the seed medium for 7 days under light, and the seed liquid of the bacteria can be obtained.

[0056] The composition of the seed culture medium of Thiobacillus denitrificans with the preservation number CCTCC NO: M2011135 is Na 2 HPO 4 1.2g / L, KH 2 PO 4 1.8g / L, NH 4 Cl 0.5g / L, KNO 3 5g / L, Na 2 S 2 o 3 10g / L, NaHCO 3 1g / L, MgSO 4 ·7H 2 O, CaCl 2 , MnSO 4 , FeCl 3 A small amount, 1L of distilled water, and the isolated Thiobacillus denitrificans with the preservation number CCTCC NO: M2011135 are placed in an oven at about 30°C for more than 7 da...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com