Nitrogen oxide yellowgreen fluorescent powder for LED and preparation method for nitrogen oxide yellowgreen fluorescent powder

A technology of yellow-green fluorescent powder and nitrogen oxides, which is applied in the direction of chemical instruments and methods, luminescent materials, etc., can solve the problems of microscopic inhomogeneity of product composition, complex process conditions, high synthesis temperature, etc., and achieve improved luminous brightness, small particles, The effect of low synthesis temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

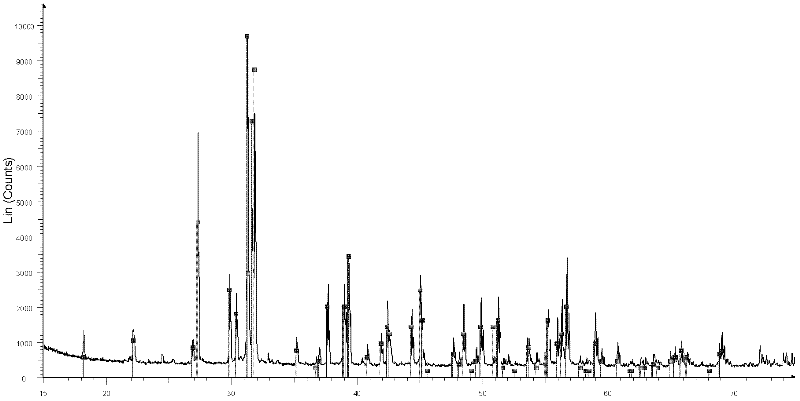

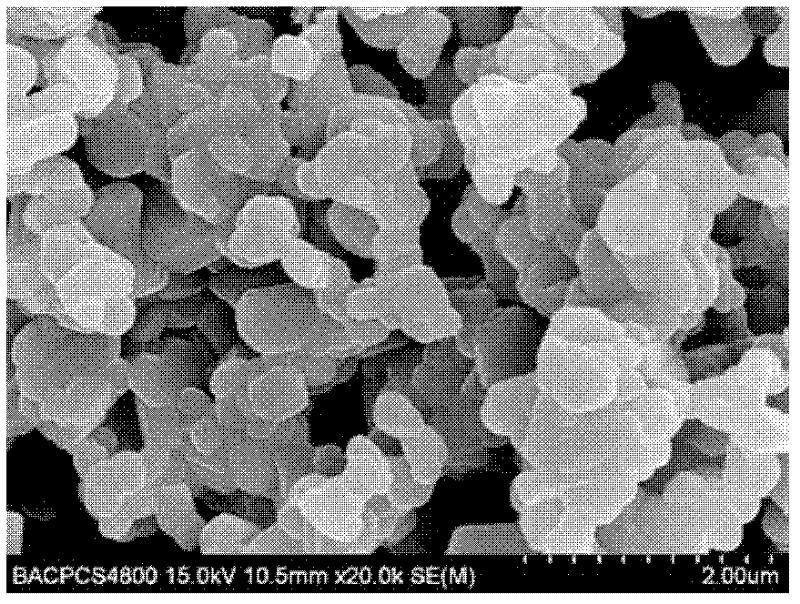

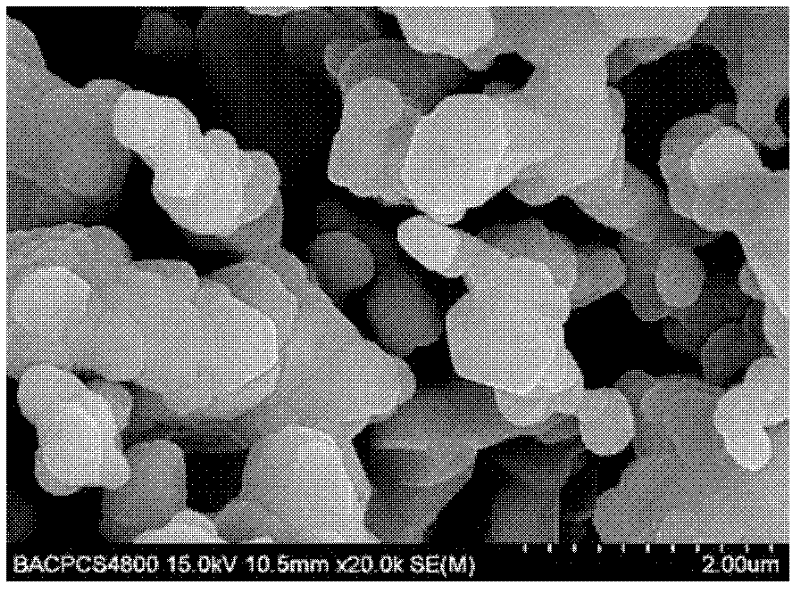

Image

Examples

Embodiment 1

[0030] Ca 0.98 Si 2 o 2 N 2 : Preparation of 0.02Eu phosphor powder:

[0031] 1) Synthesis of the precursor Ca of the yellow-green phosphor by hydrothermal method 1.96 SiO 4 :0.04Eu 2+ :

[0032] Weigh 0.5ml of tetraethyl orthosilicate (TEOS), dissolve it in a mixed solution composed of ethanol and oleic acid, wherein the content of ethanol is 25ml, and the content of oleic acid is 37.5ml; then slowly add nitric acid under stirring Europium 0.078g, mixed solution A is obtained after fully mixing and dissolving;

[0033] Take by weighing calcium acetate 0.771g, be dissolved in the mixed solution that is made up of saturated ammoniacal liquor and deionized water, wherein the content of ammoniacal liquor is 6ml, and the content of deionized water is 25ml, obtain mixed solution B after fully mixing and dissolving;

[0034] Mix the mixed solution A and the mixed solution B and pour it into a high-pressure reaction kettle, put it on a magnetic stirrer and stir for 5 hours, a...

Embodiment 2

[0039] Ca 0.98 Si 2 o 2 N2 : Preparation of 0.02Eu phosphor powder:

[0040] 1) The first step is to synthesize the precursor Ca of the yellow-green phosphor by hydrothermal method 1.96 SiO 4 :0.04Eu:

[0041] Weigh 0.5ml of tetraethyl orthosilicate (TEOS), dissolve it in a mixed solution composed of ethanol and oleic acid, wherein the content of ethanol is 25ml, and the content of oleic acid is 50ml; then slowly add europium nitrate under stirring 0.078g, mixed solution A was obtained after fully mixing and dissolving;

[0042] Take by weighing calcium acetate 0.771g, be dissolved in the mixed solution that is made up of saturated ammoniacal liquor and deionized water, wherein the content of ammoniacal liquor is 6ml, and the content of deionized water is 25ml, obtain mixed solution B after fully mixing and dissolving;

[0043] Mix the mixed solution A and the mixed solution B and pour it into a high-pressure reaction kettle, put it on a magnetic stirrer and stir for 5 h...

Embodiment 3

[0048] Ca 0.96 Si 2 o 2 no 2 : Preparation of 0.04Eu phosphor powder:

[0049] 1) Synthesis of the precursor Ca of the yellow-green phosphor by hydrothermal method 1.92 SiO 4 :0.08Eu:

[0050] Weigh 1ml of tetraethyl orthosilicate (TEOS), dissolve it in a mixed solution composed of ethanol and oleic acid, wherein the content of ethanol is 25ml, and the content of oleic acid is 57.5ml; then slowly add europium nitrate under stirring 0.139g, mixed solution A was obtained after fully mixing and dissolving;

[0051] Take calcium acetate 1.319g, be dissolved in the mixed solution that is made up of saturated ammoniacal liquor and deionized water, wherein the content of ammoniacal liquor is 10ml, and the content of deionized water is 45ml, obtain mixed solution B after fully mixing and dissolving;

[0052] Mix the mixed solution A and the mixed solution B and pour it into a high-pressure reactor, put it on a magnetic stirrer and stir for 5 hours, adjust the temperature of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com