Poly phthalimide amide composite material and preparation method thereof

A technology of polyphthalamide and composite materials, which is applied in the field of polyphthalamide composite materials and its preparation, can solve problems such as thermal stability, poor mechanical properties, and limited applications, and achieve thermal stability and mechanical Strong performance, simple and easy operation, and the effect of reducing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

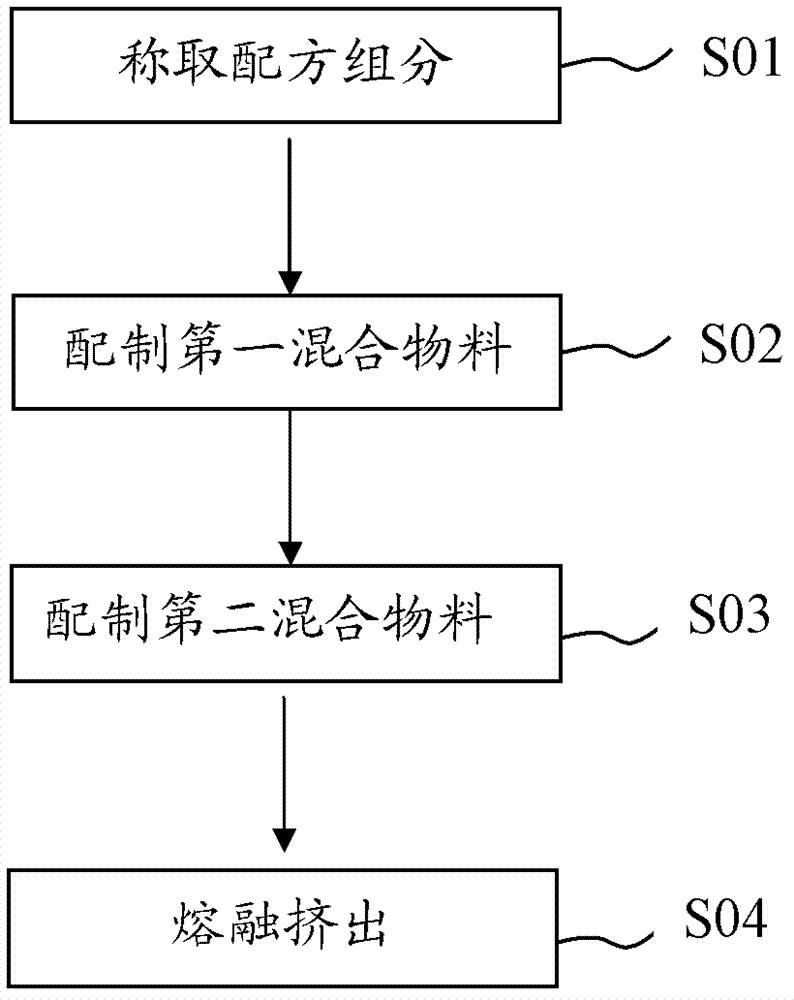

[0025] The embodiment of the present invention also provides the preparation method of the above-mentioned polyphthalamide composite material, and its technological process is as follows figure 1 shown. The method comprises the steps of:

[0026] S01. Weighing the formula components: weighing each component according to the formula of the above-mentioned polyphthalamide composite material;

[0027] S02. Prepare the first mixed material: mix the weighed polyphthalamide and thermotropic liquid crystal polymer to form the first mixed material;

[0028] S03. Prepare the second mixed material: mix the weighed zirconia and titanium dioxide to form the second mixed material;

[0029] S04. Melt extrusion: put the first mixed material into the feeding port of the extruder, and at the same time add the second mixed material into the side feeding port of the extruder for melt extrusion and granulation to obtain the polyphthalate Diformamide composites.

[0030] Specifically, in the a...

Embodiment 1

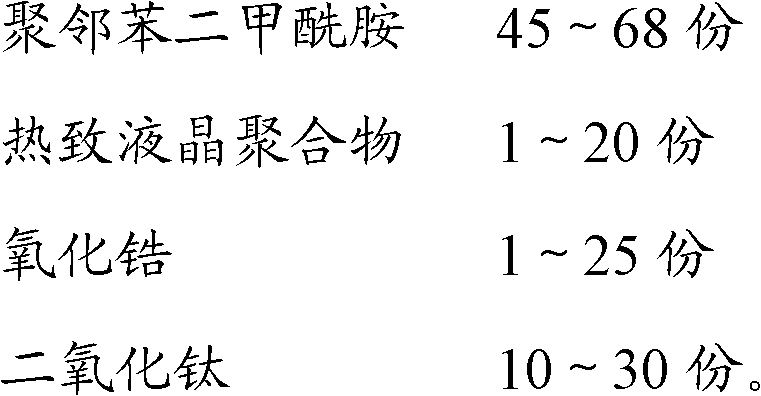

[0037] The formula component of polyphthalamide composite material parts by weight is as follows:

[0038] 68 parts of polyphthalamide, 1 part of thermotropic liquid crystal polymer, 1 part of zirconia, 30 parts of titanium dioxide. Wherein, the polyphthalamide is PPA A-1000 of Solvay Company, the thermotropic liquid crystal polymer is Zenite type thermotropic liquid crystal polymer produced by Dupont Company of the United States, and the zirconia is tetragonal polycrystal stabilized by 3mol% yttrium oxide. Zirconia (3Y-TZP), titanium dioxide is rutile titanium dioxide.

[0039] The preparation method of polyphthalamide composite material is as follows:

[0040] S11: Weigh each component according to the formula of the above-mentioned polyphthalamide composite material;

[0041]S12: Place the weighed polyphthalamide and thermotropic liquid crystal polymer components in a mixer, and mix them at a medium speed for 10 minutes to obtain a first mixed material;

[0042] S13: pla...

Embodiment 2

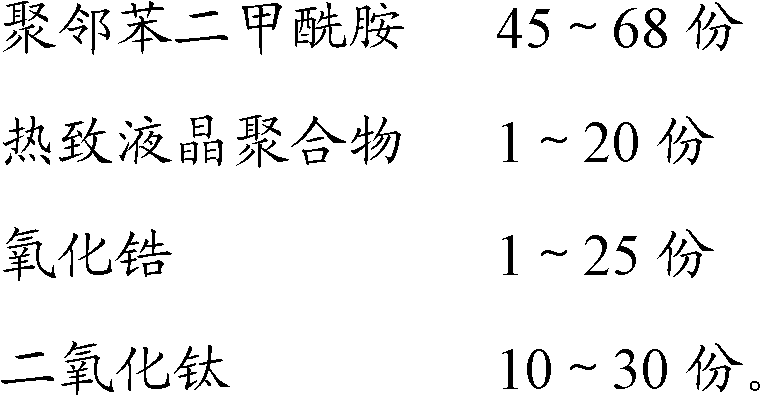

[0045] The formula component of polyphthalamide composite material parts by weight is as follows:

[0046] 65 parts of polyphthalamide, 5 parts of thermotropic liquid crystal polymer, 5 parts of zirconia, and 25 parts of titanium dioxide. Among them, the polyphthalamide is Solvay's A-4000, the thermotropic liquid crystal polymer is the Zenite type thermotropic liquid crystal polymer produced by Dupont Company of the United States, and the zirconia is tetragonal polycrystalline zirconia stabilized by 3mol% yttria. (3Y-TZP), titanium dioxide is rutile titanium dioxide.

[0047] The preparation method of polyphthalamide composite material is as follows:

[0048] S21: Weigh each component according to the formula of the above-mentioned polyphthalamide composite material;

[0049] S22: placing the weighed polyphthalamide and thermotropic liquid crystal polymer components in a mixer, and mixing them at a medium speed for 15 minutes to obtain a first mixed material;

[0050] S23: ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com