Anti-bonding copper infiltration powder and preparation method thereof

An anti-adhesion, copper powder technology, applied in the field of powder metallurgy, can solve the problems of large batches of defective products, low efficiency, corrosion holes and cracks, etc., to achieve the effect of clean and beautiful surface, simple process flow, and improved material performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

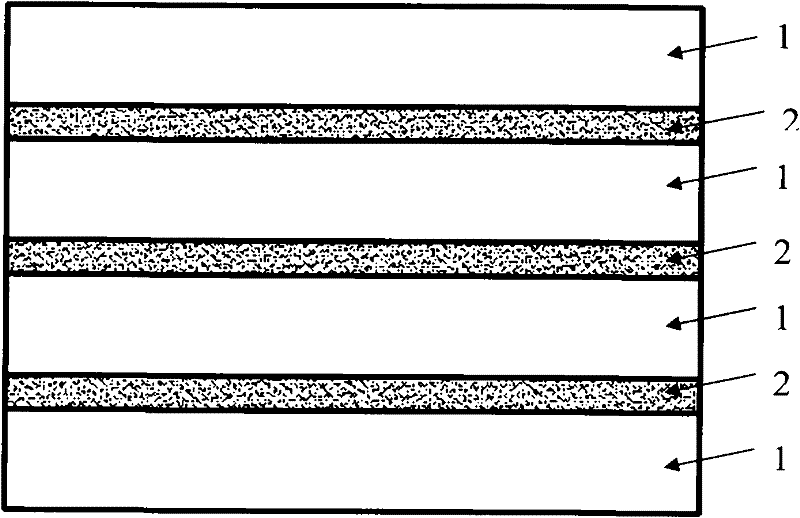

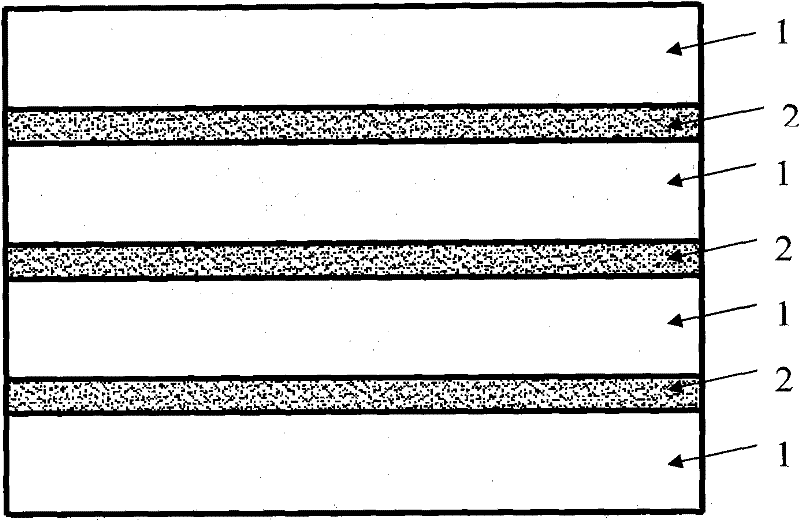

Image

Examples

Embodiment 1

[0022] A kind of anti-bonding copper penetration powder, component is Cu-1.5Fe-1.8Zn+3%MgO, raw material is: atomized copper powder (-100 mesh), superfine iron powder (-800 mesh), CuZn20 powder ( -250 mesh); the anti-adhesive additive is MgO powder, the particle size is -100 mesh, -325 mesh <15%, and the added mass percentage is 3%.

[0023] A preparation method of copper infiltrating powder, the method steps are as follows:

[0024] (1) Weigh 89.5kg of atomized copper powder, 1.5kg of superfine iron powder, and 9kg of CuZn20 powder, add 5kg of ceramic balls, and mix in a mixer for 0.5h;

[0025] (2) After the mixing process is completed, the powder is sent to the hydrogen reduction furnace for diffusion. The diffusion temperature is 650°C and the diffusion time is 1.7h. The hydrogen reduction furnace is an ammonia decomposition and reduction atmosphere, and the ratio of hydrogen to nitrogen is 3:1. ;

[0026] (3) Circulating water cooling, furnace crushing, 100 mesh sieve c...

Embodiment 2

[0029] An anti-adhesive copper penetration powder, the composition is Cu-1.8Fe-2.0Zn+5%SiO 2 , atomized copper powder (-100 mesh), ultra-fine iron powder (-800 mesh), CuZn30 powder (-250 mesh), anti-adhesive additive is SiO 2 powder, the particle size is -100 mesh, -325 mesh <15%, and the mass percentage is 5%.

[0030] A preparation method of copper infiltrating powder, the method steps are as follows:

[0031] (1) Weigh 91.53kg of atomized copper powder, 1.8kg of superfine iron powder, and 6.67kg of CuZn30 powder, add 5kg of ceramic balls, and mix in a mixer for 0.8h;

[0032] (2) After the mixing process is completed, the powder is sent to a hydrogen reduction furnace for diffusion. The diffusion temperature is 660° C., the diffusion time is 1.5 h, and the ammonia decomposition reduction atmosphere is used. The ratio of hydrogen to nitrogen is 3:1;

[0033] (3) Circulating water cooling, furnace crushing, 100 mesh sieve collection, then add 5.26kg of SiO 2 powder and 0.5...

Embodiment 3

[0036] An anti-adhesive copper infiltration powder, the composition is Cu-1.3Fe-2.5Zn+7%Al 2 o 3 , atomized copper powder (-100 mesh), ultra-fine iron powder (-800 mesh), CuZn20 powder (-250 mesh), anti-adhesive additive is Al 2 o 3 powder, the particle size is -100 mesh, -325 mesh <15%, and the mass percentage is 7%.

[0037] A preparation method of copper infiltrating powder, the method steps are as follows:

[0038] (1) Weigh 86.2kg of atomized copper powder, 1.3kg of superfine iron powder, and 12.5kg of CuZn20 powder, add 5kg of ceramic balls, and mix in a mixer for 1 hour;

[0039] (2) After the mixing process is completed, the powder is sent into a hydrogen reduction furnace for diffusion, the diffusion temperature is 720°C, the diffusion time is 1h, the ammonia decomposition reduction atmosphere, and the ratio of hydrogen to nitrogen is 3:1;

[0040] (3) Circulating water cooling, furnace crushing, 100 mesh sieve collection, then add 7.53kg of Al 2 o 3 powder and ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com