Catalyst used in complete methanation of synthesis gas at high temperature and preparation method thereof

A technology for complete methanation and catalyst, which is applied in the field of high temperature synthesis gas complete methanation catalyst and its preparation, can solve problems such as huge patent royalties, and achieve the effects of high material handling capacity, strong interaction and uniform distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

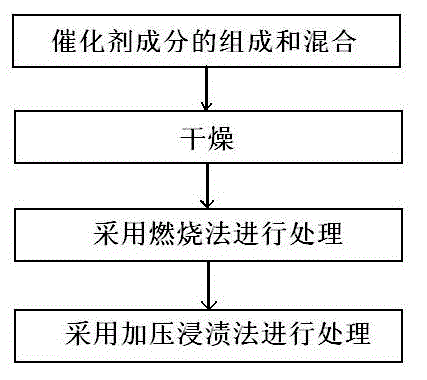

[0032] A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0033] (1) Composition and mixing of catalyst components

[0034] 8.918g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O and 0.4g of manganese nitrate Mn(NO 3 ) 2 The solution was dissolved in 50ml of deionized water, and stirred magnetically for 1 hour at 60°C to fully dissolve and mix the components of the catalyst;

[0035] (2) dry

[0036] drying the dissolved mixture in step (1) at a temperature of 110° C. for 6 hours to obtain a melt;

[0037] (3) Treated by combustion method

[0038] Heat the melt obtained by drying in step (2) to 600°C at a heating rate of 2°C per minute (during the heating process, combustion occurs spontaneously), and then bake at 600°C for 8 hours to make the melt fully Decompose to get particulate matter;

[0039] (4) Treatm...

Embodiment 2

[0050]A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0051] (1) Composition and mixing of catalyst components

[0052] 8.918 g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962 g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O, 0.4g mass concentration is 50% manganese nitrate Mn(NO 3 ) 2 solution and 0.1 g ammonium metavanadate NH 4 VO 3 Dissolve in 50ml of absolute ethanol, and stir magnetically for 2 hours at 40°C to fully dissolve and mix the components of the catalyst;

[0053] (2) dry

[0054] drying the dissolved mixture in step (1) at a temperature of 90° C. for 6 hours to obtain a melt;

[0055] (3) Treated by combustion method

[0056] Heating the melt obtained by drying in step (2) to 700°C at a heating rate of 1°C per minute and roasting at 700°C for 8 hours to fully decompose the melt to obtain granules;

[0057] (4) Treatment by pressure impr...

Embodiment 3

[0064] A method for preparing a high-temperature synthesis gas complete methanation catalyst, comprising the following steps:

[0065] (1) Composition and mixing of catalyst components

[0066] 8.918 g nickel nitrate Ni(NO 3 ) 2 . 6H 2 O, 22.066g aluminum nitrate Al(NO 3 ) 3 . 9H 2 O, 2.962 g lanthanum nitrate La(NO 3 ) 3 . 6H 2 O and 0.1 g ammonium metavanadate NH 4 VO 3 Dissolve in 50ml of absolute ethanol, and stir magnetically for 2 hours at 40°C to fully dissolve and mix the components of the catalyst;

[0067] (2) dry

[0068] drying the dissolved mixture in step (1) at 90°C for 8 hours to obtain a melt;

[0069] (3) Treated by combustion method

[0070] Heating the melt obtained by drying in step (2) to 700°C at a heating rate of 2°C per minute and roasting at 700°C for 8 hours to fully decompose the melt to obtain granules;

[0071] (4) Treatment by pressure impregnation

[0072] Grinding and screening the particles obtained in step (3);

[0073] The...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com