A sulfur-resistant methanation catalyst and its preparation method and application

A technology for sulfur-resistant methanation and catalyst, which is applied in physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc. and other problems, to achieve the effect of simple preparation process and good repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment approach

[0044] According to a preferred embodiment of the present invention, preferred method of the present invention comprises:

[0045] In the presence of an aqueous solvent, the carrier precursor and the carrier modifier precursor are mixed to obtain a solution A; in the presence of an aqueous solvent, the active component precursor and the precipitation slow-release agent are mixed to obtain a B solution; the A solution and The B solutions are mixed to obtain a mixed solution, and the obtained mixed solution is subjected to the hydrothermal treatment under airtight conditions. Thus, the methanation activity and methane selectivity of the catalyst can be further improved.

[0046] The water-containing solvent of the present invention can be all water, and other co-solvents can also be added as required, and the present invention has no special requirements for this.

[0047] According to the method of the present invention, the carrier precursor is a substance that can provide a ...

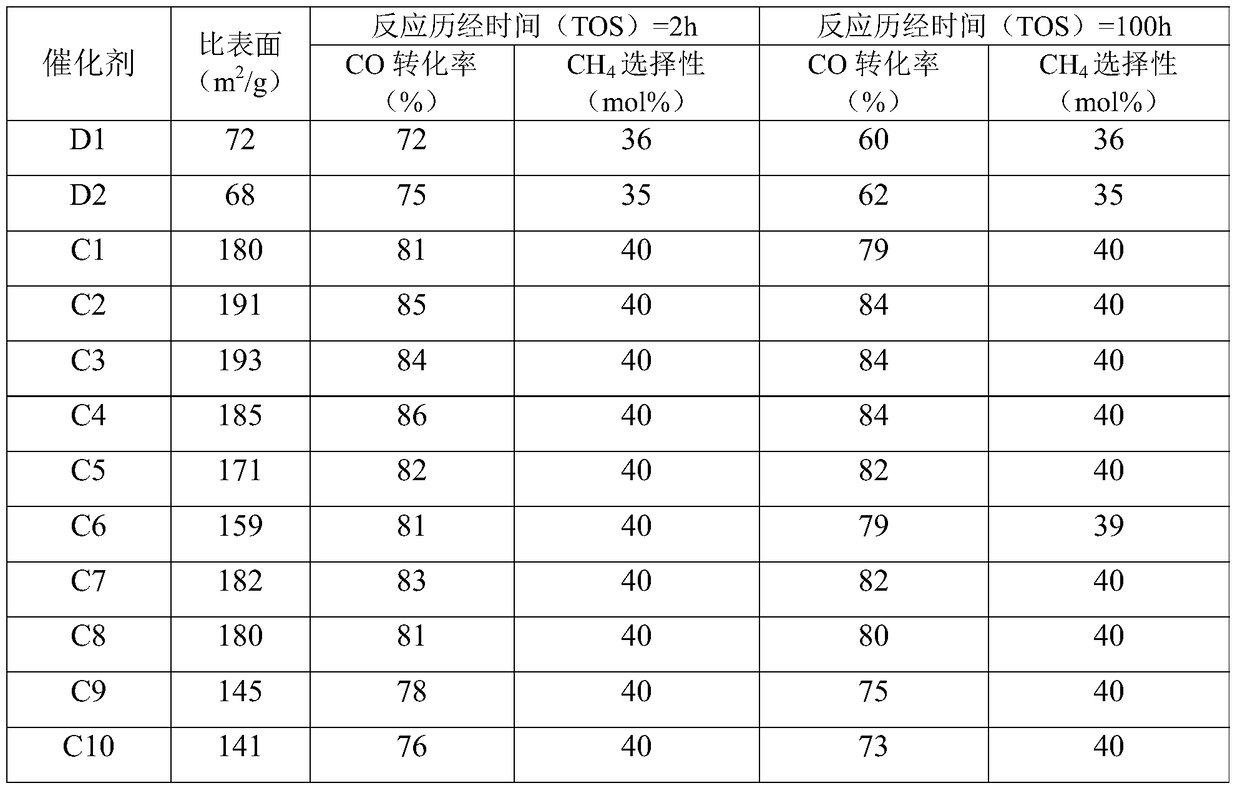

Embodiment 1

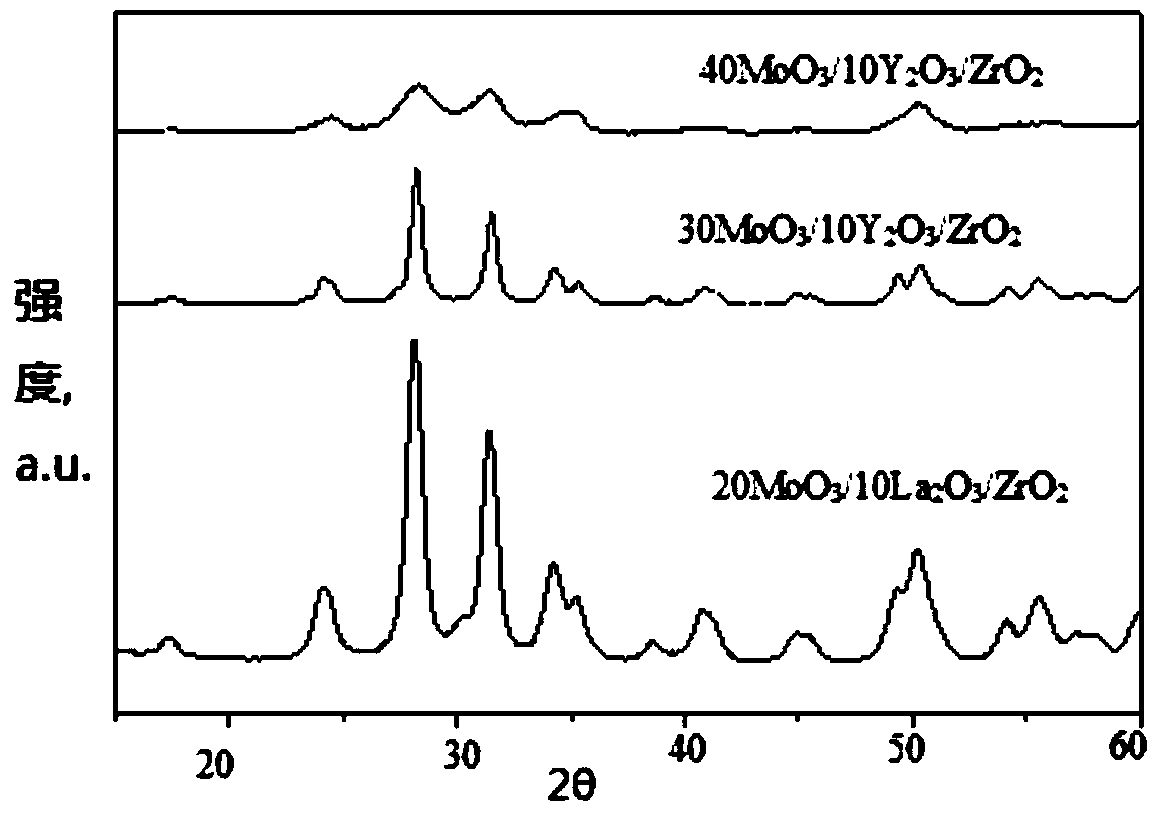

[0061] The preparation weight composition is 20MoO 3 / 10Y 2 o 3 / 70ZrO 2 Methanation Catalyst C1.

[0062] Weigh 151.8g zirconium oxynitrate (ZrO(NO 3 ) 2 2H 2 O), 17.0g Y(NO 3 ) 3 ·6H 2 O is dissolved in 1500ml water to obtain solution A, weighs 24.5g ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) and 80g urea are dissolved in 1500ml water to obtain solution B. Then the two solutions were mixed and fully stirred, then transferred to a hydrothermal kettle, and then hydrothermally treated at 160° C. for 10 h after sealing the hydrothermal kettle. Suction filter and fully wash the hydroheated slurry, dry and dehydrate at 120°C, and roast at 600°C to obtain a weight composition of 20Mo / 10Y 2 o 3 / 70ZrO 2 methanation catalyst.

Embodiment 2

[0064] The preparation weight composition is 30MoO 3 / 10Y 2 o 3 / 60ZrO 2 Methanation Catalyst C2.

[0065] Prepared according to the method of Example 1, the difference is that 151.8g zirconyl nitrate (ZrO(NO 3 ) 2 2H 2 O) into 130.1g, 24.5g ammonium heptamolybdate ((NH 4 ) 6 Mo 7 o 24 4H 2 O) change into 36.8g, all the other steps are identical with embodiment 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com