A kind of preparation method of composite wide temperature methanation catalyst

A methanation catalyst and composite technology, applied in physical/chemical process catalysts, chemical instruments and methods, chemical/physical processes, etc., can solve problems such as uneven distribution of catalyst surface, low nickel content of catalyst, catalyst agglomeration, etc., to achieve Effects of increasing effective active area, improving thermal stability, and improving mechanical strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

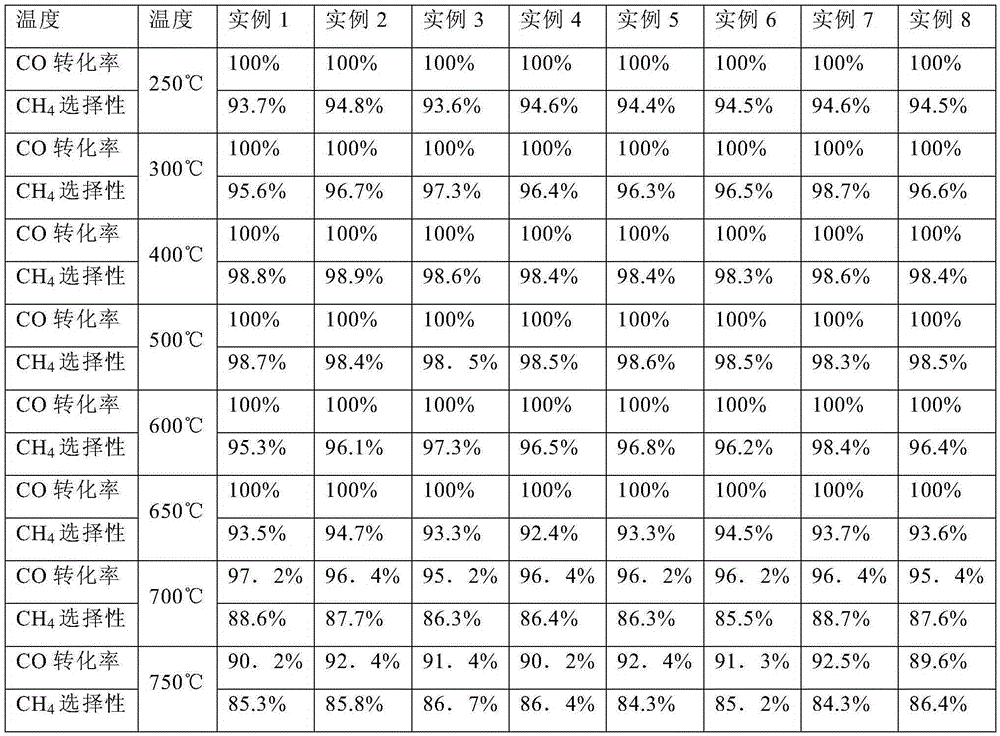

Examples

Embodiment 1

[0032]A. Preparation of porous carrier

[0033] Weigh 224.43gAl(NO 3 ) 3 9H 2 0 and 31.81gMg(NO 3 ) 2 ·6H 2 O was dissolved in 1L deionized water and stirred evenly to form a mixed salt solution, which was heated to 80°C and weighed 35.37g Na 2 CO 3 and 77.09g NaOH were dissolved in 2L deionized water to form a mixed alkali solution, and the mixed salt solution was added dropwise to the mixed alkali solution, and when the pH value of the solution reached 7.0, the dropwise addition was stopped, and the resulting precipitate was filtered and washed with deionized water for 5 The second time, the filter cake was vacuum-dried at 120°C for 4 hours, baked in a tube furnace at 450°C for 6 hours under nitrogen protection atmosphere, cooled and crushed to about 200 mesh (±10) to prepare a porous carrier.

[0034] B. Modification of porous carrier

[0035] The porous carrier of about 200 mesh prepared in step A is surface-activated with ethanol solution, and then weighed 2.66gLa...

Embodiment 2

[0043] A. Preparation of porous carrier

[0044] Weigh 202.36gAl(NO 3 ) 3 9H 2 0 and 19.09gMg(NO 3 ) 2 ·6H 2 O was dissolved in 1L deionized water and stirred evenly to form a mixed salt solution, which was heated to 80°C and weighed 57.38g Na 2 CO 3 and 50.45g NaOH were dissolved in 2L deionized water to form a mixed alkali solution, and the mixed salt solution was added dropwise to the mixed alkali solution, and when the pH value of the solution reached 7.0, the dropwise addition was stopped, and the resulting precipitate was filtered and washed with deionized water for 5 The second time, the filter cake was vacuum-dried at 110°C for 4 hours, baked in a tube furnace at 500°C for 5 hours in a nitrogen-protected atmosphere, cooled and crushed to about 200 mesh (±10) to prepare a porous carrier.

[0045] B. Modification of porous carrier

[0046] Add the porous carrier of about 200 mesh prepared in step A into the ethanol solution for surface activation, then weigh 15.9...

Embodiment 3

[0054] A. Preparation of porous carrier

[0055] Weigh 194.99gAl(NO 3 ) 3 9H 2 0 and 12.73gMg(NO 3 ) 2 ·6H 2 O was dissolved in 1L deionized water and stirred evenly to form a mixed salt solution, which was heated to 80°C and weighed 59.79g Na 2 CO 3 and 79.05g NaOH were dissolved in 2L deionized water to form a mixed alkali solution, and the mixed salt solution was added dropwise to the mixed alkali solution. When the pH value of the solution reached 7.0, the dropwise addition was stopped, and the resulting precipitate was filtered and washed with deionized water for 5 The second time, the filter cake was vacuum-dried at 110°C for 4 hours, baked in a tube furnace at 550°C for 4 hours in a nitrogen-protected atmosphere, cooled and crushed to about 200 mesh (±10) to prepare a porous carrier.

[0056] B. Modification of porous carrier

[0057] Add the porous carrier of about 200 mesh prepared in step A into the ethanol solution for surface activation, then weigh 7.97gLa(...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com