Stent for osteochondral defect repair and preparation method thereof

An osteochondral and cartilage layer technology, applied in medical science, prosthesis, etc., can solve problems such as the need to further improve the mechanical properties of the scaffold, increase the manufacturing difficulty and cost, and block the natural transition between bone and cartilage, so as to achieve good osteochondral defects. Repair effect, easy mass production, low production technical requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

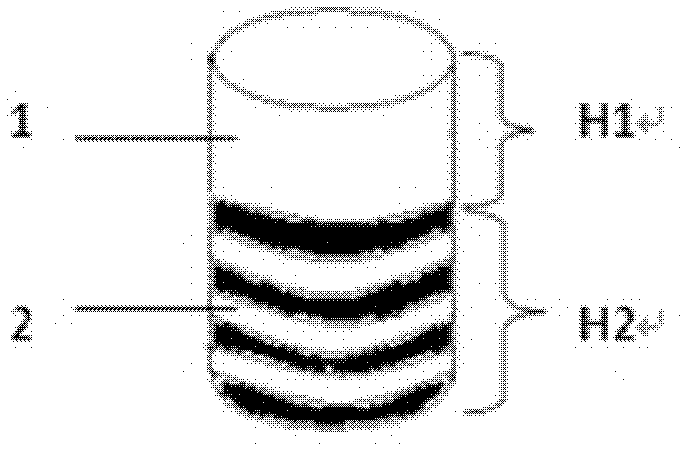

[0037] In this embodiment, the scaffold used for osteochondral defect repair is as figure 1 As shown, it is a cylinder with a diameter of 3 mm, consisting of a cartilage layer 1 and a subchondral bone layer 2, the thickness H1 of the cartilage layer 1 is 20 mm, the thickness H2 of the subchondral bone layer 2 is 25 mm, the cartilage layer 1 and the subchondral bone layer The subchondral bone layer 2 is closely integrated. The material of cartilage layer 1 is a mixture of type I collagen and chondroitin sulfate, the mass ratio of type I collagen to chondroitin sulfate is 20:1, and the material of subchondral bone layer 2 is porous titanium-chromium alloy with multiple composite pores. The diameter of the large pores is 7000-10000 μm, the diameter of the small pores is 700-1000 μm, and the porosity is 85%.

[0038] The processing steps of the preparation method are as follows:

[0039] (1) Preparation of subchondral bone layer

Embodiment 2

[0050] In this embodiment, the scaffold used for osteochondral defect repair is as figure 1 As shown, it is a cylinder with a diameter of 20 mm, consisting of a cartilage layer 1 and a subchondral bone layer 2, the thickness H1 of the cartilage layer 1 is 5 mm, the thickness H2 of the subchondral bone layer 2 is 3 mm, the cartilage layer 1 and the subchondral bone layer The subchondral bone layer 2 is closely integrated. The material of cartilage layer 1 is a mixture of type I collagen and chondroitin sulfate, the mass ratio of type I collagen to chondroitin sulfate is 5:1, and the material of subchondral bone layer 2 is porous titanium with multiple composite pores. The pore diameter is 1000-3000 μm, the small hole diameter is 10-300 μm, and the porosity is 55%. The process steps are as follows:

[0051] (1) Preparation of subchondral bone layer

[0052] Machining porous titanium with multiple composite pores to the shape and size of the subchondral bone layer 2 as describe...

Embodiment 3

[0062] In this embodiment, the scaffold used for osteochondral defect repair is as figure 1 As shown, it is a cylinder with a diameter of 6 mm, consisting of a cartilage layer 1 and a subchondral bone layer 2, the thickness H1 of the cartilage layer 1 is 3 mm, the thickness H2 of the subchondral bone layer 2 is 6 mm, the cartilage layer 1 and the subchondral bone layer The subchondral bone layer 2 is closely integrated. The material of cartilage layer 1 is a mixture of type I collagen and chondroitin sulfate, the mass ratio of type I collagen to chondroitin sulfate is 5.63:1, and the material of subchondral bone layer 2 is porous titanium oxide with multiple composite pores. The pore diameter is 1000-7000 μm, the small pore diameter is 100-700 μm, and the porosity is 70%. The process steps are as follows:

[0063] (1) Preparation of subchondral bone layer

[0064] processing porous titanium oxide with multiple composite pores into the shape and size of the subchondral bone l...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com