Lignin base skin core structure nanometer/micron fiber and preparation method thereof

A skin-core structure and lignin-based technology, applied in the field of materials, can solve the problems of low electrical conductivity, limited viscoelasticity of lignin solution, and inability to coordinate the relationship between conductivity and solvent volatilization of lignin spinnable solution at the same time, and achieve The effect of mild conditions and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0029] 1. Preparation of the core layer solution: put a mixture of 2.5g lignin and 2.5g polyacrylonitrile into 100g N, N-dimethylacetamide, stir to make it completely dissolve, and become a lignin mixed solution;

[0030] 2. Preparation of cortex solution: put 5g of polylactic acid into 50g of N,N-dimethylformamide, stir to dissolve it completely, and become a polymer solution;

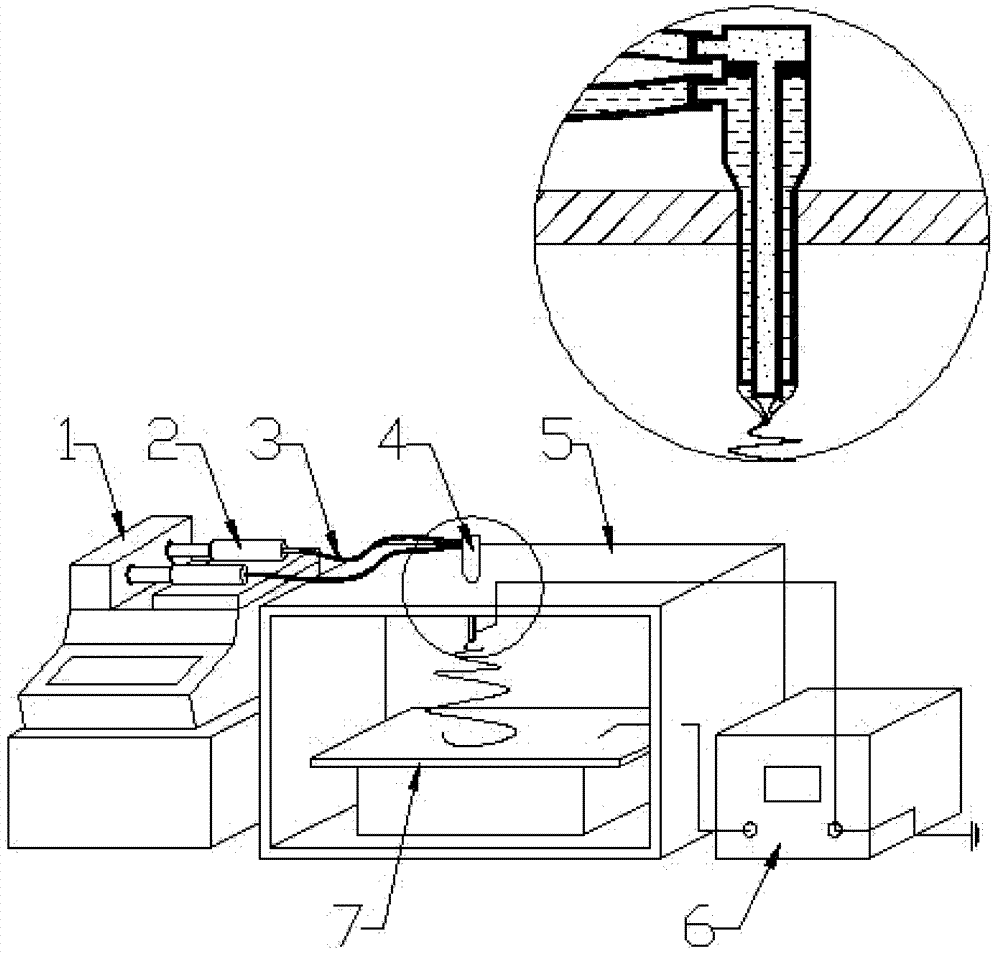

[0031] 3. Coaxial electrospinning: use as figure 1In the coaxial electrospinning device shown, the positive and negative electrodes are connected to the coaxial needle 4 and the collecting plate 7 respectively, and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the coaxial needle 4 of the electrospinning device and the grounded collecting plate 7 is 5 cm, the inner inner diameter of the coaxial needle 4 is 0.1 mm, and the outer inner diameter is 0.5 mm (that is, the outer inner diameter of the needle is greater th...

Embodiment 2

[0033] 1. Preparation of the core layer solution: put 3.25g of lignin and 1.75g of polyurethane mixture into 50g of N, N-dimethylformamide, stir to make it completely dissolve, and become a lignin mixed solution;

[0034] 2. Preparation of cortex solution: put 5 g of cellulose into 25 g of lithium chloride / dimethylacetamide with a mass ratio of 7:93, stir to make it completely dissolve, and become a polymer solution;

[0035] 3. Coaxial electrospinning: use as figure 1 In the coaxial electrospinning device shown, the positive and negative electrodes are connected to the coaxial needle 4 and the collecting plate 7 respectively, and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the electrospinning device coaxial needle 4 and the grounded collection plate 7 is 25cm, the inner inner diameter of the coaxial needle 4 is 1mm, and the outer inner diameter is 2.5mm (that is, the outer inner diam...

Embodiment 3

[0037] 1. Preparation of the core layer solution: put a mixture of 4.5g lignin and 0.5g polyethylene oxide into 5g acetone, stir to dissolve it completely, and become a polymer solution and a lignin mixed solution;

[0038] 2. Preparation of the cortex solution: put 5g of cellulose acetate into 50g of acetic acid, stir to dissolve it completely, and become a polymer solution;

[0039] 3. Coaxial electrospinning: use as figure 1 In the coaxial electrospinning device shown, the positive and negative electrodes are connected to the coaxial needle 4 and the collecting plate 7 respectively, and the coaxial needle 4 and the collecting plate 7 are located in the constant temperature and humidity container 5 . The distance between the coaxial needle head 4 of the electrospinning device and the grounded collecting plate 7 is 40cm, the inner layer inner diameter of the coaxial needle head 4 is 0.5mm, and the outer layer inner diameter is 1.5mm (that is, the outer layer inner diameter of...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com