Bismuth-ion-doped halogen phosphate fluorescent material and preparation method thereof

A technology of halophosphate and fluorescent material, applied in the field of fluorescent powder material and preparation thereof, can solve the problems of high cost, complexity, narrow color gamut and the like of the preparation method, and achieves a simple preparation method, low cost and wide emission color gamut Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

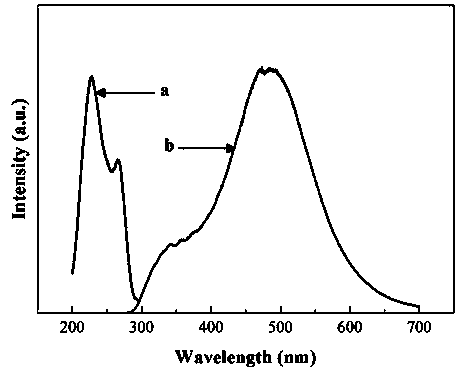

Image

Examples

Embodiment 1

[0014] (1) According to Mg ion + Ca ion: Bi ion: PO 4 Ion: molar ratio of F ion + Cl ion = 1.999: 0.001: 1.0: 0.6, weigh MgO, CaCO 3 , CaHPO 4 , CaF 2 , CaCl 2 , NH 4 Cl and Bi 2 o 3 , and mix evenly, where the molar ratio of Mg ions: Ca ions=1.0:0.999, F ions: Cl ions=0.2:0.6;

[0015] (2) Raise the temperature of the mixture obtained in step (1) to 200°C, keep it warm for 4 hours, and then introduce reducing atmosphere H 2 +N 2 , and then heated up to 1300°C, kept warm for 4 hours, then cooled to room temperature with the furnace, and finally ground to get the chemical composition formula Mg 1.0 Ca 0.999 Bi 0.001 (PO 4 ) 1.0 f 0.2 Cl 0.4 Bismuth ion-doped halophosphate fluorescent materials.

Embodiment 2

[0017] (1) According to Ba ion: Bi ion: PO 4 The molar ratio of ions:Cl ions=1.98:0.02:1.2:0.4, weigh BaCO 3 、BaHPO 4 , (NH 4 ) 2 HPO 4 , BaCl 2 、 Bi 2 o 3 , and mix well;

[0018] (2) Raise the temperature of the mixture obtained in step (1) to 400°C, keep it warm for 1.5 hours, and then introduce reducing atmosphere H 2 +N 2 , and then heated up to 1200°C, kept warm for 3 hours, then cooled to room temperature with the furnace, and finally ground to get the chemical composition formula Ba 1.98 Bi 0.02 (PO 4 ) 1.2 Cl 0.4 Bismuth ion-doped halophosphate fluorescent materials.

Embodiment 3

[0020] (1) According to Ba ion: Bi ion: PO 4 Ion: Br ion + Cl ion molar ratio = 1.6: 0.4: 1.6: 0.4, weigh BaCO 3 、BaHPO 4 、 Bi 2 o 3 、BaBr 2 , NH 4 Br, and mix well, where the molar ratio of Br ions:Cl ions=1:1;

[0021] (2) Raise the temperature of the mixture obtained in step (1) to 500°C, keep it warm for 0.5 hours, then introduce reducing atmosphere CO, then raise the temperature to 1100°C, keep it warm for 2 hours, cool it to room temperature with the furnace, and finally grind it to get the chemical composition formula for Ba 1.6 Bi 0.4 (PO 4 ) 1.6 Br 0.2 Cl 0.2 Bismuth ion-doped halophosphate fluorescent materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com