Synthetic method and application of urea monomer modified hydroxyl acrylic emulsion

A synthesis method and technology of hydroxybenzene, applied in the direction of coating, etc., can solve the problems of poor orientation, poor storage stability, and aggregation of glitter pigments, and achieve good ethanol wiping resistance, simple and easy method, and good repeatability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

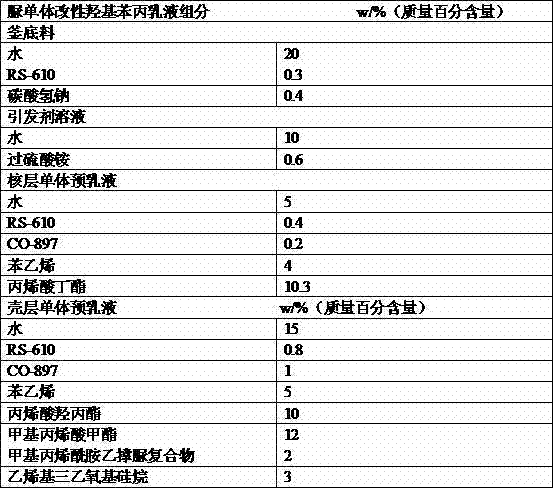

example 1

[0026]

[0027] Polymerization process:

[0028] 1. After cleaning the reaction kettle, add the bottom material and heat it to 78°C.

[0029] 2. At 78°C, add 5% of the core layer monomer pre-emulsion into the reactor, and wait for 5 minutes for the temperature to recover.

[0030] 3. Add 25% of the initiator solution, keep warm for 15 minutes after the blue light appears, then add the remaining 75% of the core layer monomer pre-emulsion, and keep warm for 30 minutes.

[0031] 4. Add the remaining shell monomer pre-emulsion and initiator solution dropwise at the same time for 2.5 hours.

[0032] 5. After feeding, raise the temperature to 85°C and keep it warm for 30 minutes.

[0033] 6. Cool down and neutralize to pH=8.0, filter and discharge.

[0034] Low-temperature baking aluminum powder paint formula for ABS plastic

[0035]

[0036] The performance index of above-mentioned coating:

[0037] Pencil hardness (70°C, 30min): ≥HB;

[0038] Pencil hardness (7 days)...

example 2

[0043]

[0044] The process steps of the production method are the same as in Example 1, wherein the temperature in step 2 is 80° C., and the dropping time in step 4 is 3 hours.

[0045] Formula for self-drying white paint on urea-formaldehyde plastics

[0046]

[0047] The performance index of above-mentioned paint:

[0048] Surface dry time: 45min;

[0049] Working time: 4.5h

[0050] Pencil hardness (7 days): ≥H

[0051] Adhesion (cross-cut method): 13% fall off

[0052] Water resistance (at room temperature): no whitening within 48 hours

[0053] Gloss (60 。 ): 70

[0054] Alcohol resistance (500g weight): ≥50 times.

example 3

[0056]

[0057] The process steps of the production method are the same as those in Example 1, wherein the temperature in step 2 is 80° C., and the dropping time in step 4 is 3.5 hours.

[0058] Low temperature self-drying paint formula for ABS plastic

[0059]

[0060] The performance index of above-mentioned paint:

[0061] Surface dry time: 35min;

[0062] Working time: 5h

[0063] Pencil hardness (7 days): ≥H

[0064] Adhesion (cross-cut method): 10% fall off,

[0065] Water resistance (room temperature): 48h does not turn white.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Surface dry time | aaaaa | aaaaa |

| Surface dry time | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com