Inorganic foaming heat-insulation material and preparation method thereof

A thermal insulation, inorganic foaming technology, applied in ceramic products, other household appliances, household appliances, etc., can solve the problems of easy breeding of bacteria, poor heat resistance, polluted air, etc., and achieve good hole sealing effect and improve strength. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

[0028] 1) Fully mix 100 parts of water glass and 1 part of azodicarbonamide, and place it at room temperature for 60 hours to obtain a white viscous slurry;

[0029] 2) In the above slurry, add 1 part of lithium petalite powder, 3 parts of hydroxypropyl methylcellulose, 1 part of vinyl acetate-ethylene copolymer emulsion (solid content 50%), 5 parts of hollow glass microspheres ( The particle size is 65~120μm), fully stirred;

[0030] 3) Pour the mixed slurry prepared in step 2) into a mold, bake in an oven, heat up to 700°C for 11 hours, keep the temperature constant for 1 hour, and shape;

[0031] 4) After the molding is completed, cool, take out of the furnace, and demould to obtain an inorganic foaming material;

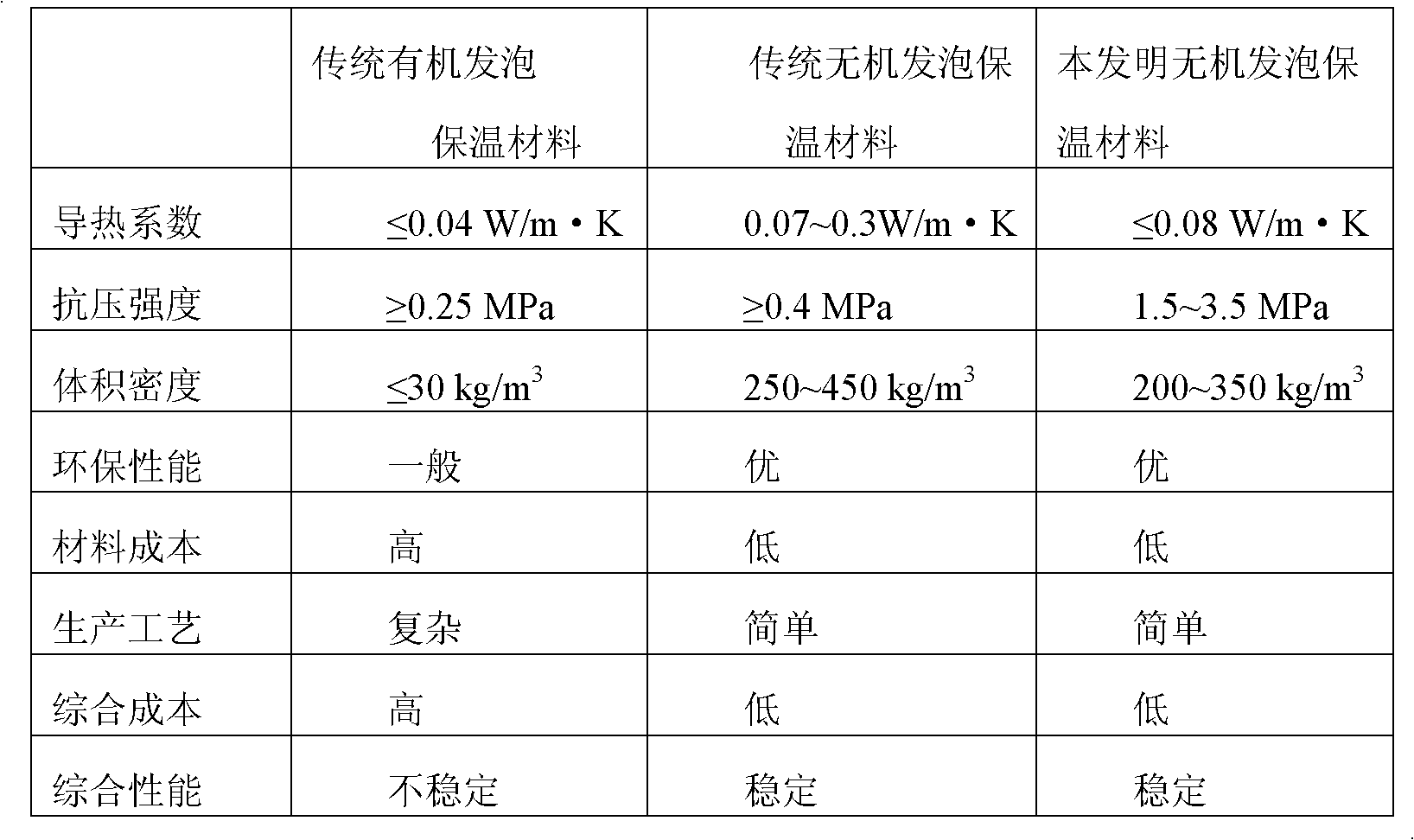

[0032] 5) The bulk density of the thermal insulation material prepared by this method is 333.24kg / m 3 , an inorganic foaming material with a compressive strength of 2.55MPa and a thermal conductivity of 0.072W / m·K.

specific Embodiment 2

[0033] 1) Fully mix 80 parts of water glass and 5 parts of azodicarbonamide, and place at room temperature for 48 hours to obtain a white viscous slurry;

[0034] 2) Add 1 part of mullite quartz powder, 1 part of polyvinyl alcohol, and 3 parts of hollow glass microspheres (60-115 μm in particle size) into the above slurry, and stir thoroughly;

[0035] 3) Pour the mixed slurry prepared in step 2) into a mold, bake in an oven, heat up to 500°C for 8 hours, keep the temperature for 1 hour, and shape;

[0036] 4) After the molding is completed, cool, take out of the furnace, and demould to obtain an inorganic foaming material;

[0037] 5) The bulk density of the thermal insulation material prepared by this method is 289.14kg / m 3 , an inorganic foaming material with a compressive strength of 1.91MPa and a thermal conductivity of 0.069W / m·K.

specific Embodiment 3

[0038] 1) Fully mix 90 parts of water glass and 2.5 parts of azodicarbonamide, and place it at room temperature for 48 hours to obtain a white viscous slurry;

[0039] 2) In the above slurry, add 2 parts of cordierite powder, 2 parts of polyvinylpyrrolidone, 1 part of acrylic emulsion (solid content 40%), 8 parts of floating beads (particle size is 120 ~ 550 μm), fully stir, get mixed pulp;

[0040] 3) Pour the mixed slurry prepared in step 2) into a mold, bake in an oven, heat up to 400°C for 6 hours, keep the temperature for 1 hour, and shape;

[0041] 4) After the molding is completed, cooling and demoulding are performed to obtain an inorganic foaming material;

[0042] 5) The bulk density of the thermal insulation material prepared by this method is 307.02kg / m 3 , an inorganic foaming material with a compressive strength of 2.39MPa and a thermal conductivity of 0.065W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com