Production method for light sleeper made of microcrystal material

A technology of microcrystalline materials and production methods, applied in glass production and other directions, to achieve the effects of high production efficiency, low energy consumption, and natural resource conservation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

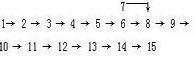

Image

Examples

Embodiment 1

[0048] Mix the above raw materials together and mix evenly, put them into the melting furnace and melt them into molten glass at a temperature of 1520°C, then quench them into granules below 6mm, dry them with drying equipment, and directly crush them into powders with a fineness of 40 mesh Then send it into the mixing equipment, and add a certain amount of foaming agent, mix evenly, weigh and install the mold, put it into the crystallization kiln and heat it to 1020°C for controlled microcrystallization and foaming heat treatment, crystallization Foaming and heat preservation time is 20 minutes, then direct annealing and slow cooling, cooling to 150°C for 13 hours, demoulding, grinding and polishing after exiting the kiln, and light green-brown microcrystalline material light-weight sleeper after passing the test.

[0049] Embodiment two

[0050] Yellow River Sediment 60% Calcite Powder 25.6% Alumina 0.2%

[0051] Barium Carbonate 4.9% Sodium Carbonate 7.5% Borax 1.6%

Embodiment 2

[0053] Mix the above raw materials together and mix evenly, put them into the melting furnace and melt them into molten glass at a temperature of 1500°C, then quench them into granules below 6mm, dry them with a drying equipment, and directly crush them into powders with a fineness of 80 mesh Then send it into the mixing equipment, and add a certain amount of foaming agent, mix evenly, weigh and install the mold, put it into the crystallization kiln and heat it to 980°C for controlled microcrystallization and foaming heat treatment, crystallization Foaming and holding time for 30 minutes, then direct annealing and slow cooling, cooling to 180°C for 12 hours, demoulding, grinding and polishing after exiting the kiln, and passing the test to obtain a light-weight sleeper made of dark cyan-brown microcrystalline material.

[0054] Embodiment Three

[0055] Yellow River sediment 71% Calcite powder 21.2% Alumina 0.0%

[0056] Barium Carbonate 2.0% Sodium Carbonate 4.4% Borax 1.5...

Embodiment 3

[0058] Mix the above raw materials together and mix evenly, put them into the melting furnace and melt them into molten glass at a temperature of 1450°C, then quench them into granules below 6mm, dry them with a drying equipment, and directly crush them into powders with a fineness of 150 mesh Then send it into the mixing equipment, and add a certain amount of foaming agent, mix evenly, weigh and install the mold, put it into the crystallization kiln and heat it to 880°C for controlled microcrystallization heat treatment, and the crystallization holding time is 40 Minutes, then direct annealing and slow cooling, cooling to 160°C for 11 hours, demoulding, grinding and polishing after leaving the kiln, and passing the test to obtain a light-weight sleeper made of dark brown microcrystalline material.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| flexural strength | aaaaa | aaaaa |

| crystal size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com