Microbiological degradation method for nitrobenzene industrial wastewater

A technology for microbial degradation and industrial wastewater, applied in the field of biological treatment of pollutants, can solve the problems of poor biodegradability of nitrobenzene, low ability to resist the impact load of influent water quality, short survival time, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

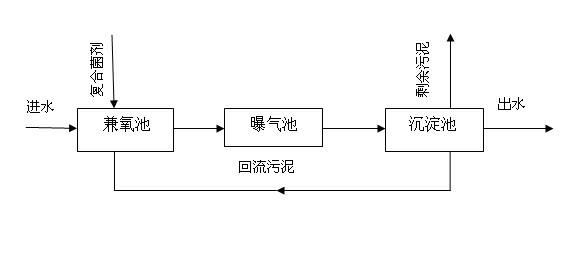

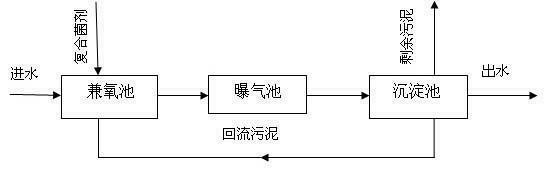

[0024] This embodiment treats nitrobenzene-containing wastewater produced during the production process of a pharmaceutical factory in the southwest region. The concentrations of CODcr and nitrobenzene are 2500-5800mg / L and 65-150mg / L, respectively, the water intake is 200 tons / day, and the main biological process is a batch SBR reactor.

[0025] See figure 1 , Adopt the compound bacterial liquid of Pseudomonas, Maltotrophic oligotrophomonas, Acinetobacter baumannii, Aquaspirillum, Acidobacter avenae, Alcaligenes faecalis and Bacillus for domestication culture, three Level expansion training. After the initial dosage of 10 tons of compound bacterial agent, keep the reactor running stably for 20 days, and the effluent CODcr after treatment <100mg / L, nitrobenzene content <0.05mg / L, the effect is better.

Embodiment 2

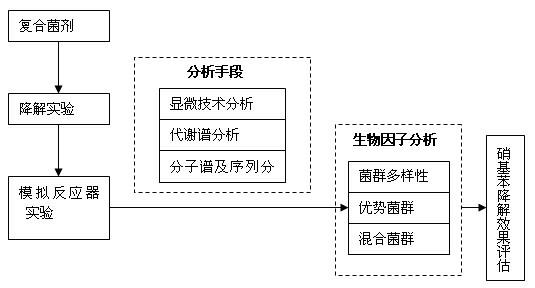

[0027] For the composite microbial agent used in Example 1, a small test evaluation was carried out in a microbiological laboratory of a university. The main evaluation route is shown in the attachment figure 2 .

[0028] The laboratory simulated wastewater is a pharmaceutical factory wastewater sample with a nitrobenzene content of 216 mg / L and a CODcr of about 14000. The biological treatment reactor used is a batch SBR reactor with a daily treatment volume of 40L and a residence time of 4h (1h). Facilitate mixing with oxygen, 1h continuous aeration, 1h standing for precipitation, 1h effluent), CODcr after treatment <100mg / L, nitrobenzene concentration <0.05mg / L.

[0029] The biological factor analysis of the mixed solution in the reactor by molecular biology shows that the main dominant bacterial groups in the mixed solution are: Pseudomonas, Stenotrophomonas, Acinetobacter, and Metamorphosis. Bacteria, Acidobacter avenae, Pseudomonas perforatum, Pseudomonas alcaligenes,...

Embodiment 3

[0031] In this example, 1) to 3) verify the simulated wastewater treatment effect of a single strain lacking a composite microbial agent. 4) ~ 7) Verify the simulated wastewater treatment effect of a single strain.

[0032] The laboratory simulated wastewater is a pharmaceutical factory wastewater sample with a nitrobenzene content of 300 mg / L and a CODcr of about 20,000. The biological treatment reactor used is a batch SBR reactor with a daily treatment water volume of 40L and a residence time of 4h (1h Facilitate mixing with oxygen, continuous aeration for 1h, standing for 1h for precipitation, 1h for effluent)

[0033] 1) Pseudomonas deficient complex bacteria

[0034] After treatment, the effluent CODcr=18564.46mg / L, and the concentration of nitrobenzene=48.46mg / L.

[0035] 2) Compound bacterial agent Maltostrobotrophomonas hypotrophic

[0036] After treatment, the effluent CODcr=17668.00mg / L, and the concentration of nitrobenzene=186.34mg / L.

[0037] 3) Compound bacterial agent Ac...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com