Method for preparing strontium hydroxide octahydrate granular crystals

A technology of strontium hydroxide octahydrate and strontium hydroxide, applied in the direction of calcium/strontium/barium oxide/hydroxide, etc., can solve the problem of high impurity content, achieve low impurity content, avoid waste water discharge, and reduce chemical raw materials The effect of consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

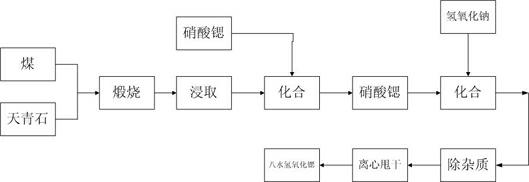

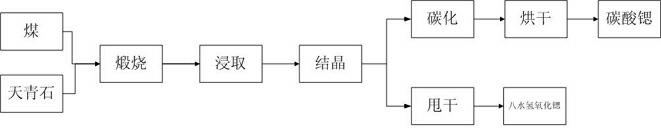

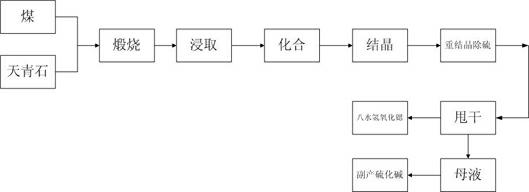

Method used

Image

Examples

Embodiment 1

[0023] A method for preparing strontium hydroxide octahydrate granular crystals, the specific steps are as follows:

[0024] (1) Grinding lapis lazuli and anthracite to 3.35 mm, mixing them at a weight ratio of 100:20, and calcining them in a rotary kiln at 900°C-1100°C to obtain crude strontium sulfide;

[0025] (2) leaching the crude strontium sulfide prepared in step (1) in water at 85°C-95°C for 2 hours to obtain a strontium sulfide solution;

[0026] (3) Heat and clarify the above-mentioned strontium sulfide solution in a clarification tank at 85°C-95°C for 1 hour;

[0027] (4) After hot filtering the clarified strontium sulfide solution in step (3), send it into the crystallization tank, and use the iodometric method to titrate the S in the solution in the tank. 2- content, according to S 2- The content of Na required for the reaction is calculated + content, thereby determine the required amount of NaOH, add excess 8% NaOH in the clarification tank, turn on the agita...

Embodiment 2

[0032] A method for preparing strontium hydroxide octahydrate granular crystals, the specific steps are as follows:

[0033] (1) Grinding lapis lazuli and anthracite to 5 mm, mixing them at a weight ratio of 100:40, and calcining them in a rotary kiln at 900°C-1100°C to obtain crude strontium sulfide;

[0034] (2) leaching the crude strontium sulfide prepared in step (1) in water at 85°C-95°C for 1 hour to obtain a strontium sulfide solution;

[0035] (3) Heat and clarify the above strontium sulfide solution in a clarification tank at 85°C-95°C for 2 hours;

[0036] (4) After hot filtering the clarified strontium sulfide solution in step (3), send it into the crystallization tank, and use the iodometric method to titrate the S in the solution in the tank. 2- content, according to S 2- The content of Na required for the reaction is calculated + content, thereby determine the required amount of NaOH, add excess 8% NaOH in the clarification tank, turn on the agitator, and the ...

Embodiment 3

[0040] A method for preparing strontium hydroxide octahydrate large particle crystals, the specific steps are as follows:

[0041] (1) Grinding lapis lazuli and anthracite to 4 mm, mixing them at a weight ratio of 100:30, and calcining them in a rotary kiln at 900°C-1100°C to obtain crude strontium sulfide;

[0042] (2) leaching the crude strontium sulfide prepared in step (1) in water at 85°C-95°C for 2 hours to obtain a strontium sulfide solution;

[0043] (3) Heat and clarify the above-mentioned strontium sulfide solution in a clarification tank at 85°C-95°C for 1 hour;

[0044] (4) After hot filtering the clarified strontium sulfide solution in step (3), send it into the crystallization tank, and use the iodometric method to titrate the S in the solution in the tank. 2- content, according to S 2- The content of Na required for the reaction is calculated +content, thereby determine the required amount of NaOH, add excess 8% NaOH in the clarification tank, turn on the agi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com