Steel wire rod for annealing-free solder wire and production process thereof

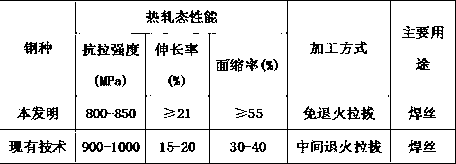

A production process, welding wire steel technology, applied in the field of metallurgy, can solve problems such as unsatisfactory shrinkage and elongation performance, poor plasticity index of welding wire steel wire rod, complex production process, etc., to achieve good comprehensive mechanical properties and plasticity index Excellent, chemically stable effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

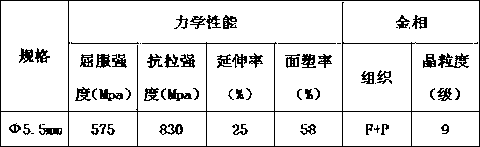

Examples

Embodiment 1

[0024] The non-annealing welding wire steel wire rod of this embodiment is composed of the following components by weight percentage: C: 0.08%, Mn: 1.29%, Si: 0.48%, P: 0.01%, S: 0.008%, Mo: 0.35%, Ni: 0.56%, Cu: 0.04%, Ti: 0.05%, Al: 0.03%, and the balance is Fe.

[0025] The production process of the annealing-free welding wire steel wire rod in this embodiment includes the following steps: billet inspection→steel billet heating→high-pressure water descaling→rough and intermediate rolling and pre-finishing rolling→first water cooling→finishing rolling unit→second water cooling → Reduction and sizing rolling → third water cooling → silk spinning → air cooling → finishing → storage;

[0026] In the billet heating process, the atmosphere of the heating furnace is controlled, the air combustion is set to 1.0%, and the temperature in the soaking section is controlled at 1120°C;

[0027] In the high-pressure water descaling process, the descaling pressure is controlled to ensure ...

Embodiment 2

[0035] The non-annealing welding wire steel wire rod of this embodiment is composed of the following components by weight percentage: C: 0.09%, Mn: 1.31%, Si: 0.51%, P: 0.008%, S: 0.004%, Mo: 0.36%, Ni: 0.55%, Cu: 0.05%, Ti: 0.04%, Al: 0.03%, and the balance is Fe.

[0036] The production process of the annealing-free welding wire steel wire rod in this embodiment includes the following steps: billet inspection→steel billet heating→high-pressure water descaling→rough and intermediate rolling and pre-finishing rolling→first water cooling→finishing rolling unit→second water cooling → Reduction and sizing rolling → third water cooling → silk spinning → air cooling → finishing → storage;

[0037] In the billet heating process, the atmosphere of the heating furnace is controlled, the air combustion is set to 1.2%, and the temperature of the soaking section is controlled at 1200 °C;

[0038] In the high-pressure water descaling process, the descaling pressure is controlled to ensur...

Embodiment 3

[0046] The non-annealing welding wire steel wire rod of this embodiment is composed of the following components by weight percentage: C: 0.07%, Mn: 1.25%, Si: 0.4%, P: 0.02%, S: 0.002%, Mo: 0.2%, Ni: 0.5%, Cu: 0.02%, Ti: 0.2%, Al: 0.01%, and the balance is Fe.

[0047] The production process of the annealing-free welding wire steel wire rod in this embodiment includes the following steps: billet inspection→steel billet heating→high-pressure water descaling→rough and intermediate rolling and pre-finishing rolling→first water cooling→finishing rolling unit→second water cooling → Reduction and sizing rolling → third water cooling → silk spinning → air cooling → finishing → storage;

[0048] In the billet heating process, the atmosphere of the heating furnace is controlled, the air combustion is set to 1.1%, and the temperature of the soaking section is controlled at 1150°C;

[0049] In the high-pressure water descaling process, the descaling pressure is controlled to ensure the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com