Foaming agent suitable for oil-field development

A foaming agent technology for oilfield development, applied in the foaming agent field of oilfield foam profile control, oil displacement, drilling and drainage and gas recovery, it can solve the problems that limit the wide application of foam, and achieve good biodegradability and foaming And the effect of good foam stability and wide adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0017] The foam scanner was used to determine the foamability and foam stability of different foaming agents. The foam measuring instrument by airflow method was used to inject nitrogen at a flow rate of 30 mL / min at a constant temperature of 45°C and injected for 5 minutes. The foam volume generated at the end of the gas injection is used as the foaming performance of the blowing agent, that is, the foaming volume (V). The time taken when the foam volume decays to half is used as the foam stability evaluation index, namely the foam half-life (t). Foam Composite Index (FCI) can consider both foaming volume and foam half-life at the same time, and its calculation relationship is FCI=3V·t / 4.

[0018] The foam properties of different foaming agents are shown in Table 1. It can be seen from Table 1 that the foaming volume of different foaming agents is higher than 160mL, the half-life of the foam is higher than 60min, and the comprehensive foam index is higher than 8000mL·min, indic...

Embodiment 2

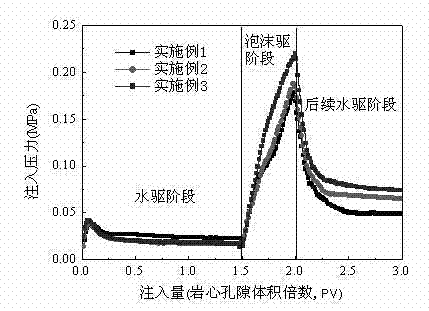

[0022] The experimental method of foam profile control and oil displacement effect of foaming agent is as follows: (a) Select a 4.5cm × 4.5cm × 30cm artificial three-layer heterogeneous core with a coefficient of variation of 0.72 and a permeability of 1100×10 -3 μm 2 Around, the porosity is 22-25%. Evacuate to -1.0MPa for two hours, then saturate with water, and measure the core pore volume. Saturate the simulated oil of Daqing Oilfield (viscosity 9.5cp), determine the oil saturation, and age for more than 12 hours. (b) Water drive oil to 98% water cut, record injection pressure, oil production and water production, and calculate water drive recovery. (d) In foam flooding, nitrogen is selected as gas, gas and liquid are injected at the same time, gas-liquid ratio is 1:1, and 0.5 times the core pore volume (PV) of the foaming agent solution to be tested is injected. Then follow-up water flooding to 98% water cut, record the injection pressure, oil production and water producti...

Embodiment 3

[0028] The foaming agent drainage capacity is measured. Under the condition of 90℃ simulating gas well tubing, the foaming agent solution is foamed by air agitation, and the drainage capacity in a certain period of time is measured. The drainage capacity of different foaming agents is shown in Table 3. It can be seen from Table 3 that the liquid carrying capacity of different foaming agents is close to 150 mL, and the foaming agent numbered 3# takes the shortest time. This shows that different foaming agents have good drainage capacity, which can meet the needs of gas well foam drainage and gas recovery.

[0029] Table 3 Drainage capacity of foaming agent

[0030] Experiment number Foaming agent composition and ratio Liquid carrying capacity (mL) Liquid carrying time (min) 1# Sodium α-olefin sulfonate (containing 14 to 16 carbons) 0.5wt%, lauramide propyl dimethyl betaine 0.35wt%, partially hydrolyzed polyacrylamide (molecular weight 16 million) 0.02%145.613.4 2# Sodium α-ole...

PUM

| Property | Measurement | Unit |

|---|---|---|

| coefficient of variation | aaaaa | aaaaa |

| porosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com