Preparation method of hyperbranched water-based polyurethane hydroxy component

A polyurethane hydroxyl and water-based technology, applied in polyurea/polyurethane coatings, coatings, etc., can solve the problems of long drying time of water-based two-component polyurethane paint film, low molecular weight of the final product, poor hardness, etc., and achieve high branching degree , Increase the cross-linking density, increase the effect of contact probability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

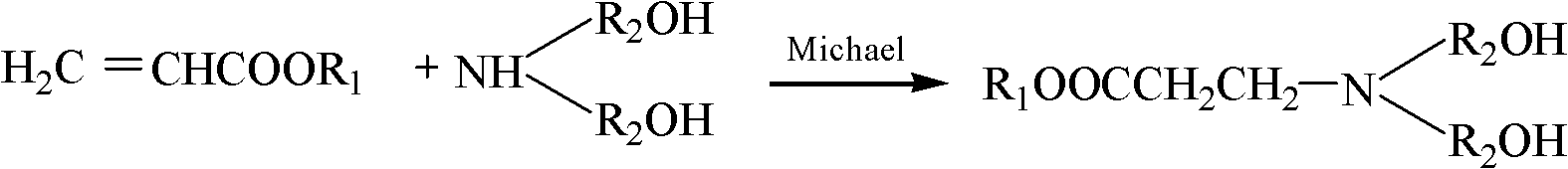

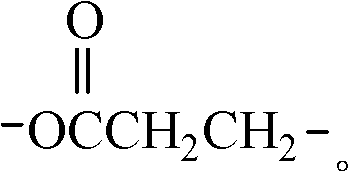

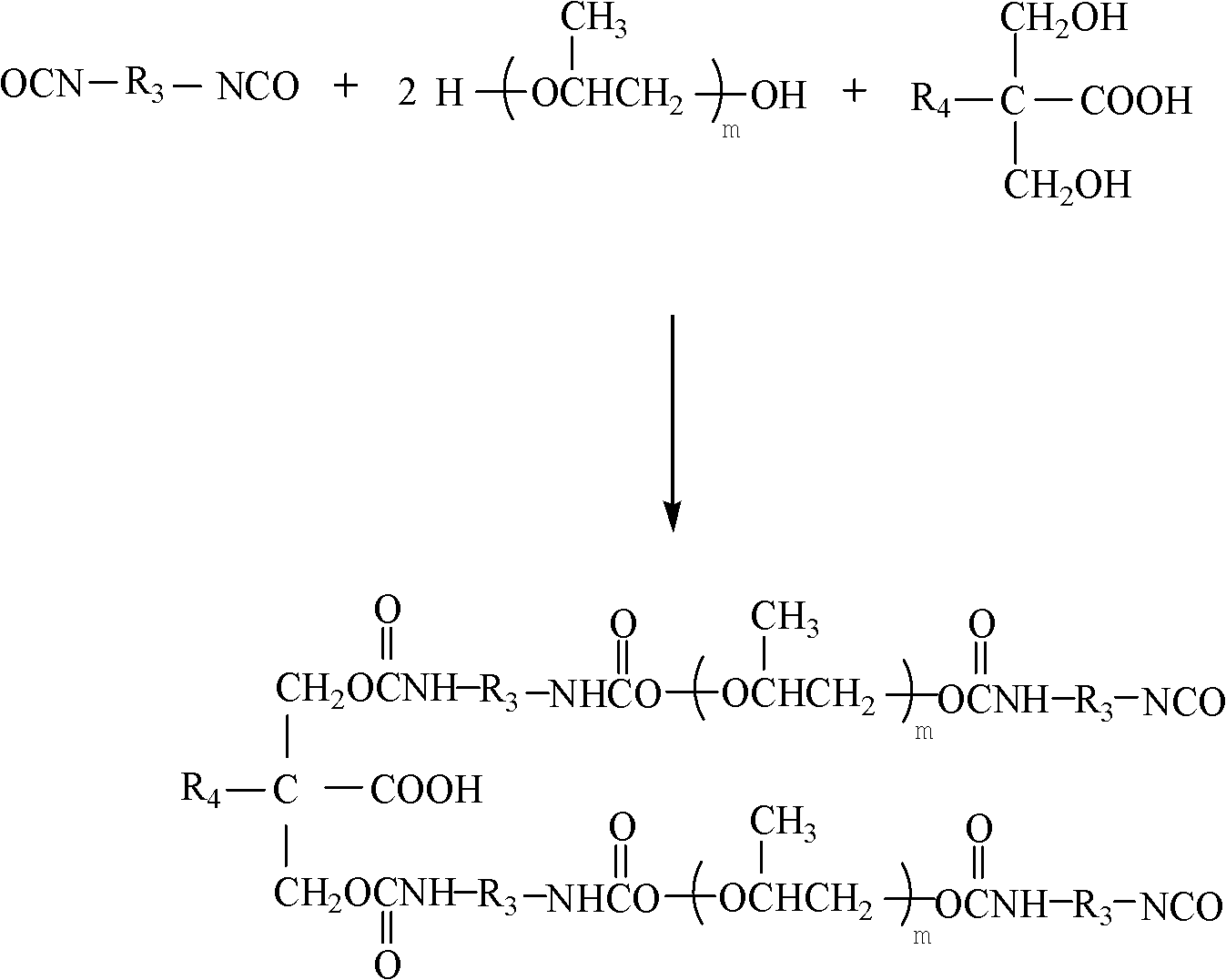

Method used

Image

Examples

Embodiment 1

[0041] Weigh 86.09g methyl acrylate, 105.14g diethanolamine and 100ml methanol in a four-necked flask, the mixture is at room temperature and logical N 2 Under normal circumstances, after stirring for 30 minutes, the temperature was raised to 35°C and maintained for 4 hours, and then vacuumed to remove methanol to obtain a colorless and transparent oily N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer.

[0042] Weigh 1.36g of pentaerythritol, 7.6492g of N, N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.04g of p-toluenesulfonic acid in a four-necked flask, heat the mixture to 120h°C for 2h, then add 15.2984g of N , N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.08g p-toluenesulfonic acid were placed in a four-necked flask, kept at 120h°C for 2h, and finally vacuumed to remove the generated methanol to obtain a light yellow oil The second generation of hydroxyl-terminated hyperbranched poly(amine-ester).

[0043]Weigh 1.48g of ...

Embodiment 2

[0046] Weigh 86.09g methyl acrylate, 105.14g diethanolamine and 100ml methanol in a four-necked flask, the mixture is at room temperature and logical N 2 Under normal circumstances, after stirring for 30 minutes, the temperature was raised to 35°C and maintained for 4 hours, and then vacuumed to remove methanol to obtain a colorless and transparent oily N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer.

[0047] Weigh 1.36g pentaerythritol, 7.6492g N, N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.04g p-toluenesulfonic acid in a four-neck flask, heat the mixture to 120h°C for 1h, then add 15.2984gN , N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.08g p-toluenesulfonic acid in a four-necked flask, kept at 120h°C for 1h, and continued to add 30.5968g N, N-dihydroxyethyl-3 - methylalanine monomer and 0.16g p-toluenesulfonic acid in a four-necked flask, kept at 120h°C for 2h, and finally evacuated to remove the generated methanol t...

Embodiment 3

[0051] Weigh 86.09g methyl acrylate, 105.14g diethanolamine and 100ml methanol in a four-necked flask, the mixture is at room temperature and logical N 2 Under normal circumstances, after stirring for 30 minutes, the temperature was raised to 35°C and maintained for 4 hours, and then vacuumed to remove methanol to obtain a colorless and transparent oily N,N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer.

[0052] Weigh 1.36g pentaerythritol, 7.6492g N, N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.04g p-toluenesulfonic acid in a four-neck flask, heat the mixture to 120°C for 0.5h, then add 15.2984 gN, N-dihydroxyethyl-3-aminopropionic acid methyl ester monomer and 0.08g p-toluenesulfonic acid in a four-necked flask, kept at 120°C for 0.5h, and continued to add 30.5968g N, N-dihydroxyethyl -Methyl 3-aminopropionate monomer and 0.16g p-toluenesulfonic acid were placed in a four-necked flask, kept at 120°C for 1h, and then 61.1936g N, N-dihydroxyeth...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com