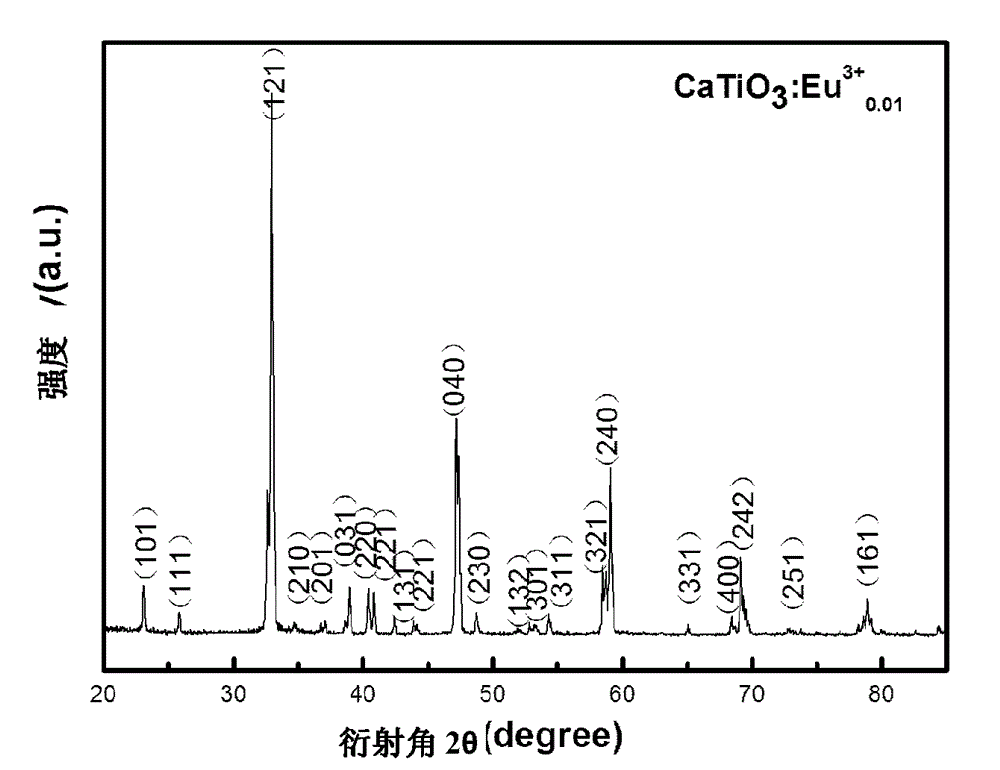

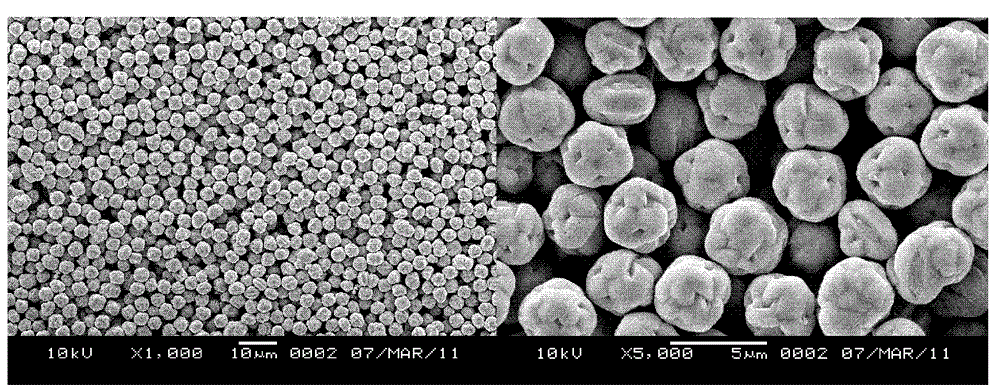

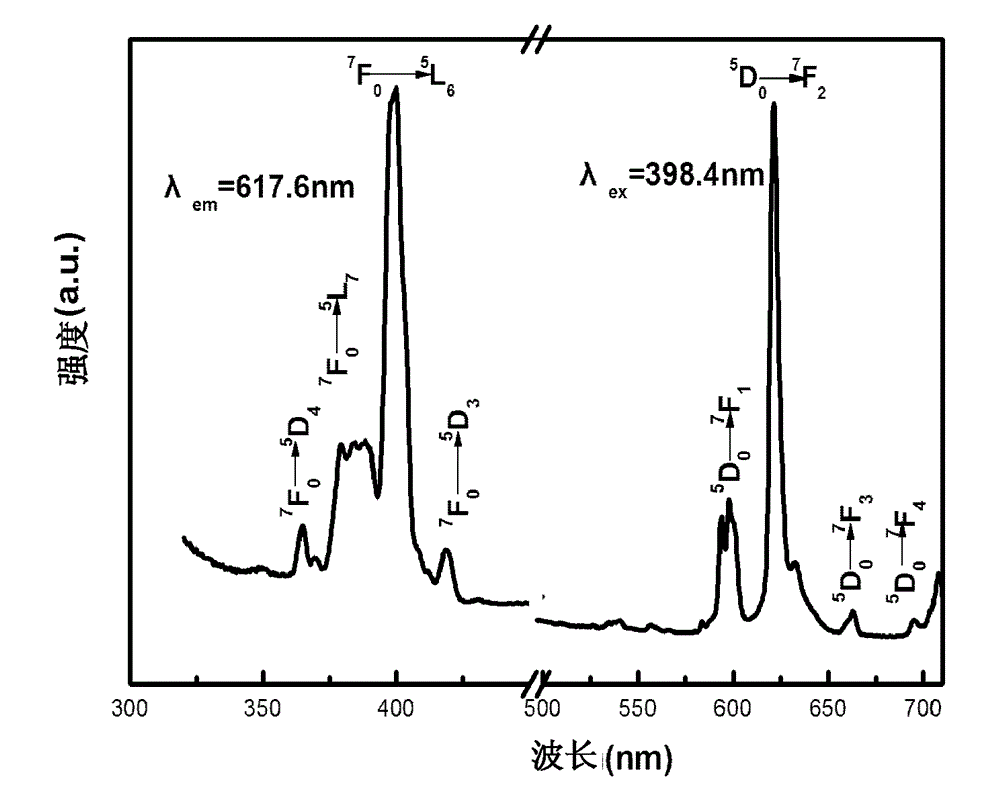

Preparation method for europium-doping calcium titanate fluorescent powder

A calcium titanate and phosphor technology, applied in chemical instruments and methods, luminescent materials, etc., can solve the problems of phosphor powder thermal stability and low luminous index, difficult to achieve high-quality packaging of phosphor powder, and luminous efficiency to be further improved , to achieve good application prospects, reduce energy consumption, and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Take 1.74ml of n-tetrabutyl titanate, disperse it in 10ml of absolute ethanol, add dropwise 10ml of 3mol / L ammonia solution to make it all react into a white precipitate, and centrifuge and wash it with deionized water for 3 times. Then add the above precursor to the mixed solution of 15ml ethylene glycol and 15ml ethylenediamine and stir for 50min to fully disperse the mixed solution. Dissolve 2.275g calcium acetate, 0.036g europium nitrate and 3.0g sodium hydroxide solution, 1ml of polyethylene glycol 200, and stirred for 50min at a rotation speed of 200r / min, so that the obtained solution was in the form of a suspension. The above-mentioned reactants were poured into a reaction kettle with a volume of 100ml, and then kept at 180° C. for 12 hours, and then cooled to room temperature. The product was collected by washing and centrifugation, washed twice with ethanol, then washed twice with pH = 1 hydrochloric acid solution, then washed three times with deionized water,...

Embodiment 2

[0027] Take 1.78ml of n-tetrabutyl titanate, disperse it in 12ml of absolute ethanol, add dropwise 15ml of 2mol / L ammonia solution to make it all react into a white precipitate, and centrifuge and wash it with deionized water for 4 times. Then add the above precursor to the mixed solution of 17ml ethylene glycol and 20ml ethylenediamine and stir for 40min to fully disperse the mixed solution. Dissolve the mixed solution of 2.448g calcium acetate, 0.104g europium nitrate, 3.5g sodium hydroxide solution, 2ml of polyethylene glycol 400, and stirred for 40min at a rotation speed of 300r / min to make the obtained solution into a suspension. The above reactant was poured into a reaction kettle with a volume of 100ml, and then kept at 200°C for 10 hours, and then cooled to room temperature. The product was collected by washing and centrifugation, first washed 3 times with ethanol, then washed 3 times with pH = 2 hydrochloric acid solution, and then washed 3 times with deionized water,...

Embodiment 3

[0029] Take 1.85 ml of n-tetrabutyl titanate, disperse it in 15 ml of absolute ethanol, add dropwise 20 ml of 1 mol / L ammonia solution to make it all react into a white precipitate, and centrifuge and wash it with deionized water for 5 times. Then add the mixture of 28ml ethylene glycol and 25ml ethylenediamine to the above precursor and stir for 30min to fully disperse it in the mixture. Dissolve 2.673g calcium acetate, 0.202g europium nitrate and 3.8g hydroxide Sodium solution and 2ml of polyethylene glycol 600 were stirred for 20min at a rotation speed of 500r / min to make the obtained solution into a suspension. The above-mentioned reactant was poured into a reaction kettle with a volume of 100ml, and then kept at 220° C. for 8 hours, and then cooled to room temperature. The product was collected by washing and centrifugation, first washed 3 times with ethanol, then washed 4 times with pH = 3 hydrochloric acid solution, and then washed 5 times with deionized water, and fina...

PUM

| Property | Measurement | Unit |

|---|---|---|

| wavelength | aaaaa | aaaaa |

| emission peak | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com