White hollow titanium dioxide microsphere and preparation method thereof

A technology of titanium dioxide and microspheres, which is applied in the field of preparation of new materials, can solve the problems of limited application, complex templates in the process, and increase of core-shell, etc., and achieve the effect of simple preparation process, easy-to-obtain raw materials, and uniform size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0015] ① Disperse 0.07 g of organic copolymer microspheres of methyl methacrylate and ethyl acrylate in 60 mL of absolute ethanol, add 0.10 g of polyvinylpyrrolidone, add 0.30 g of butyl titanate under rapid stirring conditions, react for 120 min, and centrifuge After separation and freeze-drying, white spherical organic copolymer microspheres / titanium dioxide core-shell composite particles are obtained.

[0016] ②Put the organic copolymer microspheres / titanium dioxide core-shell composite particles in the air atmosphere and bake them at 500°C to obtain white hollow titanium dioxide microspheres with a uniform particle size of about 120nm and a relative density of 1.31g / cm 3 .

example 2

[0018] ① Disperse 0.07 g of organic copolymer microspheres of methyl methacrylate and butyl acrylate in 60 mL of absolute ethanol, add 0.10 g of polyvinylpyrrolidone, add 0.50 g of butyl titanate under rapid stirring conditions, react for 120 min, and centrifuge After separation and freeze-drying, white spherical organic copolymer microspheres / titanium dioxide core-shell composite particles are obtained.

[0019] ②The organic copolymer microspheres / titanium dioxide core-shell composite particles were calcined in the air atmosphere at 500°C to obtain white hollow titanium dioxide microspheres with a uniform particle size of about 140nm and a relative density of 1.38g / cm 3 .

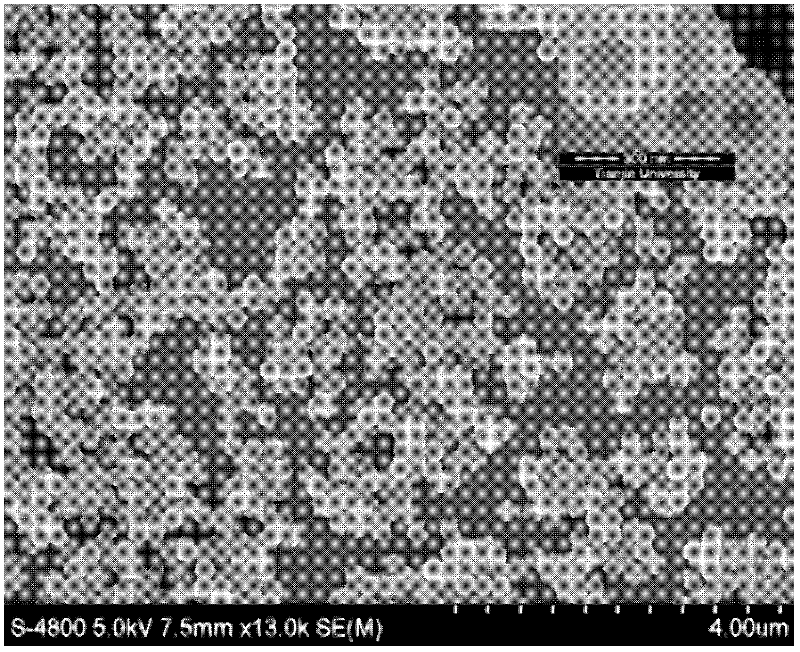

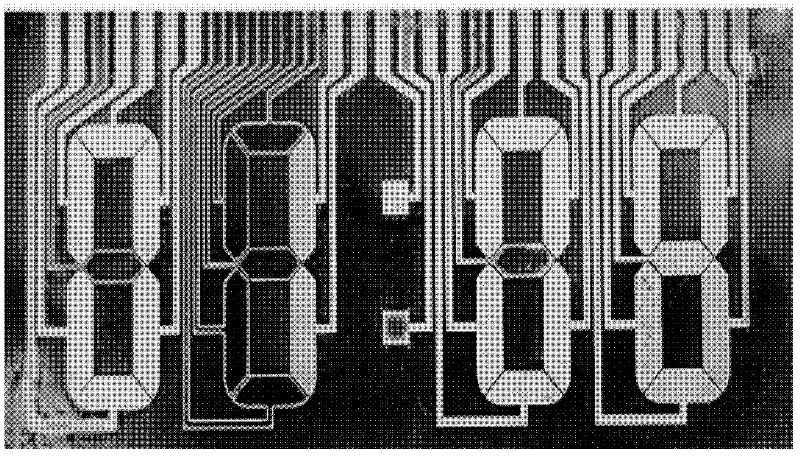

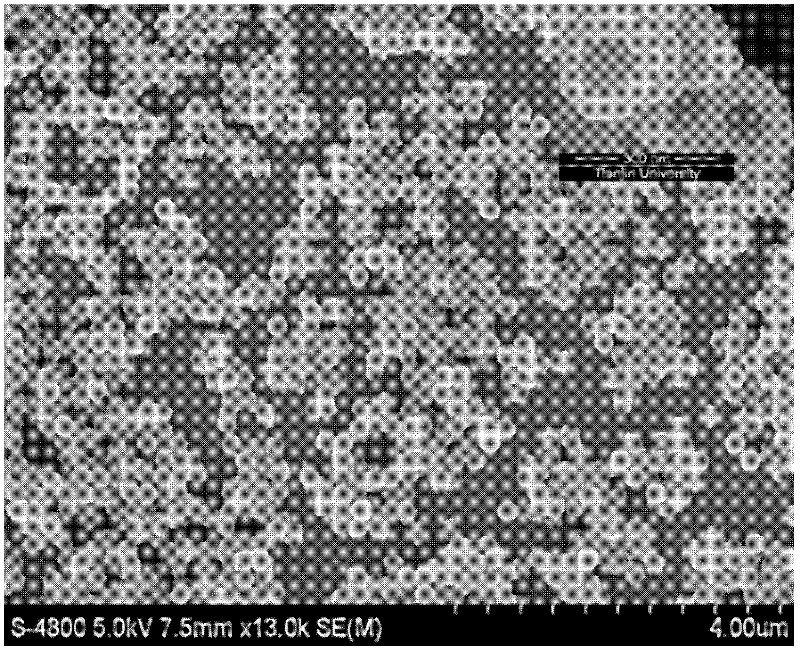

[0020] Such as figure 1 Shown is the scanning electron micrograph of the white hollow titania microspheres that example 2 prepares; figure 2 It is an electrophoretic display effect diagram of white hollow titanium dioxide microspheres prepared in Example 2.

example 3

[0022] ① Disperse 0.07 g of organic copolymer microspheres of methyl methacrylate and ethyl acrylate in 60 mL of absolute ethanol, add 0.10 g of polyvinylpyrrolidone, add 0.50 g of butyl titanate under rapid stirring conditions, react for 120 min, and centrifuge After separation and freeze-drying, white spherical organic copolymer microspheres / titanium dioxide core-shell composite particles are obtained.

[0023] ②The organic copolymer microspheres / titanium dioxide core-shell composite particles were calcined in the air atmosphere at 700°C to obtain white hollow titanium dioxide microspheres with a uniform particle size of about 160nm and a relative density of 1.62g / cm 3 .

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com