Preparation method of liquid rubber asphalt water-proof paint

A technology of asphalt waterproof coating and liquid rubber, which is applied in the direction of asphalt coating, recycled rubber coating, anti-corrosion coating, etc. It can solve the problems affecting stability and achieve good stability, excellent bonding performance and less foam

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

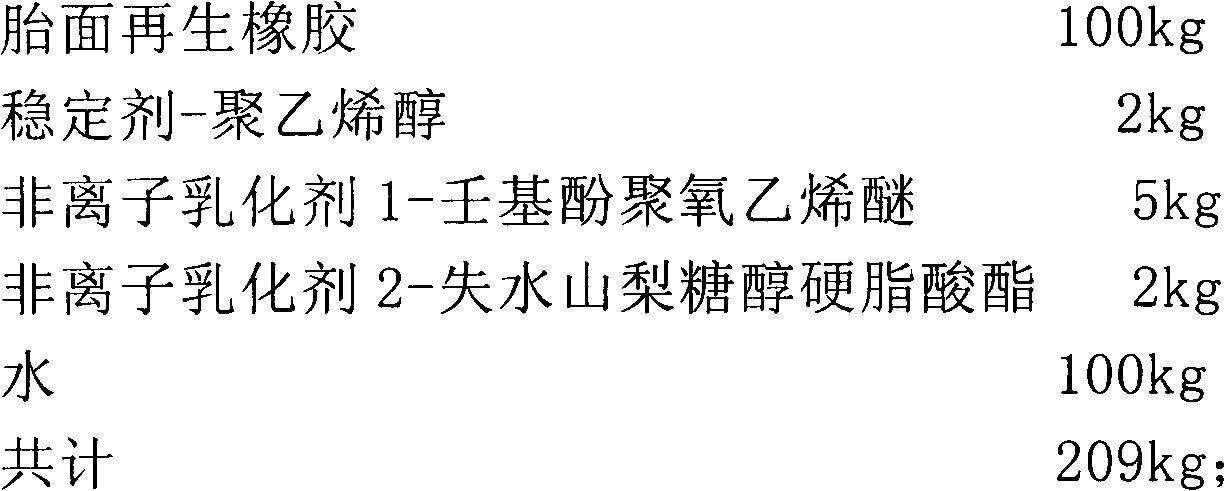

[0053] Preparation of nonionic regenerated rubber emulsion:

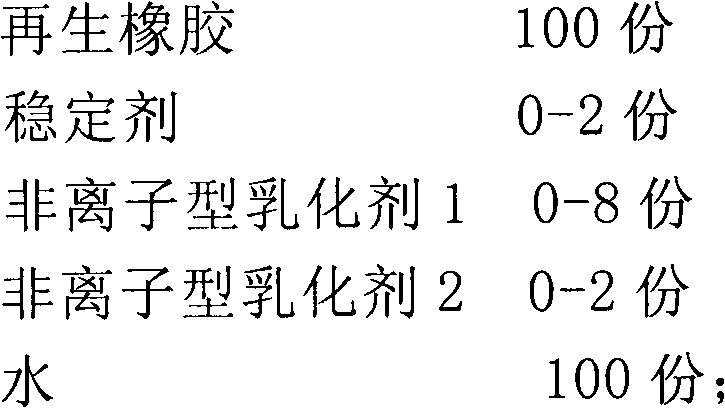

[0054] Taking the total weight of regenerated rubber as the basic amount, the ingredients are formulated according to the following weight ratio:

[0055]

[0056] After the above-mentioned regenerated tread rubber is plasticized for 8-10 times at a temperature of 70±5°C, the above-mentioned stabilizer-polyvinyl alcohol and non-ionic emulsifier 2-sorbitan fatty acid sugar are added After mixing evenly, place the lower piece in a shearing machine, keep the temperature of 80-120°C, add the above-mentioned nonionic emulsifier 1-nonylphenol polyoxyethylene ether and water, and cut 20 at a speed of 450 rpm Minutes, turn to high speed 960 rpm and cut for 3 minutes, that is, non-ionic regenerated rubber emulsion;

[0057] Preparation of nonionic asphalt emulsion:

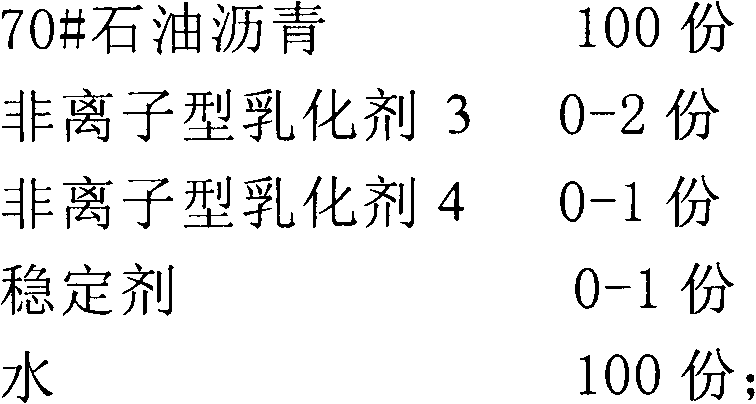

[0058] Take the weight of asphalt as the basic amount, and mix according to the following weight ratio:

[0059]

[0060]Melt and dehydrate the above-m...

Embodiment 2

[0073] Preparation of nonionic regenerated rubber emulsion:

[0074] Taking the total weight of regenerated rubber as the basic amount, the ingredients are formulated according to the following weight:

[0075]

[0076] Make nonionic regenerated rubber emulsion with the method for example 1;

[0077] Preparation of nonionic asphalt emulsion:

[0078] Take the weight of asphalt as the basic amount, and mix according to the following weight ratio:

[0079]

[0080] Obtain non-ionic asphalt emulsion with the method for embodiment 1;

[0081] Preparation of liquid rubber asphalt waterproof coating:

[0082]

[0083]

[0084] The liquid rubber asphalt waterproof paint 200kg is obtained with the method for embodiment 1.

[0085] Its physical properties reach the JC / T 975-2005 standard index,

[0086] Tensile strength, MPa 1.1,

[0087] Elongation at break, % 820,

[0088] Low temperature flexibility, ℃ -25,

[0089] Water impermeability, (0.3MPa, 30min) no leakag...

Embodiment 3

[0092] 1. Preparation of nonionic regenerated rubber emulsion

[0093] Taking the total weight of regenerated rubber as the basic amount, the ingredients are formulated according to the following weight:

[0094]

[0095] Make nonionic regenerated rubber emulsion with the method for example 1;

[0096] 2. Preparation of non-ionic asphalt emulsion

[0097]

[0098] Obtain non-ionic asphalt emulsion with the method for embodiment 1;

[0099] 3. Preparation of liquid rubber asphalt waterproof coating

[0100]

[0101] The liquid rubber asphalt waterproof paint 200kg is obtained with the method for embodiment 1.

[0102] Its physical performance index meets the index of JC / T 975-2005 standard:

[0103] Tensile strength, MPa 1.0

[0104] Elongation at break, % 850

[0105] Low temperature flexibility, ℃ -25

[0106] Water impermeability (0.3MPa, 30min) no leakage

[0107] The emulsion prepared by it is delicate and the particle size is 2-3μ.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com