Cathode active material of lithium ion battery, preparation method thereof and lithium ion battery

A negative electrode active material, lithium ion battery technology, applied in battery electrodes, secondary batteries, nanotechnology for materials and surface science, etc., can solve the problems of poor cycle performance of negative electrode active materials, improve cycle performance, prevent The effect of agglomeration, avoiding volume change

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

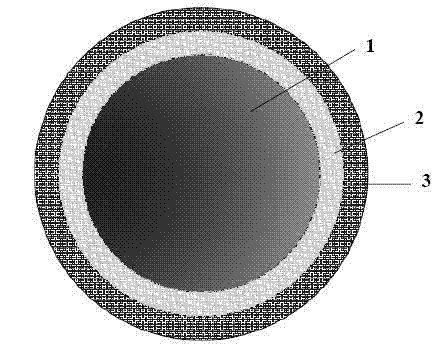

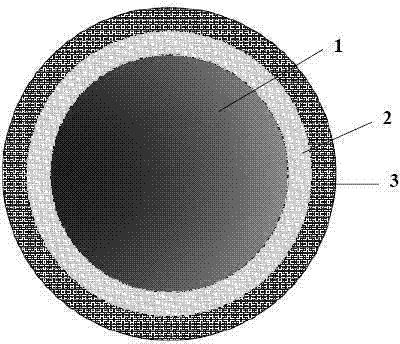

Image

Examples

Embodiment 1

[0041] (1) Composite material preparation:

[0042] A. First add 900g of graphite and 100g of nano silicon powder (median particle size is 50nm) to 2000g of organic solvent mixed with acetone and tetrahydrofuran (ratio 1:1), then add 10g of modified polyvinylidene fluoride; Stir to a uniform and stable solid-liquid mixture, stir at 80°C for 3 hours, and after most of the solvent evaporates, dry it in vacuum at 120°C to obtain a graphite-nano-silicon composite material;

[0043] B. In a polytetrafluoroethylene-lined autoclave, add 2000g distilled water and 20g cobalt chloride hexahydrate, and stir to form a uniform solution; add 10g polyethylene glycol 6000 dispersant under strong stirring; then add graphite- For nano-silicon composite materials, add 15g of ammonium oxalate under continuous stirring; then, add an appropriate amount of distilled water to keep the filling degree of the reactor at 80% and seal it. , after washing and drying, put the obtained solid in a box furnac...

Embodiment 2

[0049] Composite materials, button batteries and full batteries were prepared in the same manner as in Example 1, except that nickel chloride hexahydrate was used to replace cobalt chloride hexahydrate, ammonium oxalate was replaced by ammonia, and the amount of nickel chloride hexahydrate was 25g. , the amount of ammonia water added is 10g, keep the filling degree of the reactor at 90%, heat up to 55°C under continuous stirring, and keep at a constant temperature for 24h to obtain a precursor suspension. After filtering, washing, and drying, the resulting solid is placed in a box Calcined in an argon atmosphere at 300°C for 6 hours in a type furnace to obtain a composite material S2 whose outermost layer is nickel oxide;

[0050] According to the same method as in Example 1, button battery A2 and full battery B2 were produced respectively.

Embodiment 3

[0052] Composite materials, button batteries and full batteries were prepared in the same manner as in Example 1, except that nano-zinc powder was used instead of nano-silicon powder as the middle layer material, and the calcination temperature was 320°C to obtain a composite material in which the middle layer was nano-zinc S3;

[0053] According to the same method as in Example 1, button battery A3 and full battery B3 were produced respectively.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average particle diameter | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com