Method for preparing SPE (solid polymer electrolyte) anodic oxygen evolution catalysts for water electrolysis

An electrocatalyst, water electrolysis technology, applied in the direction of electrodes, electrolysis process, electrolysis components, etc., can solve the problems of harsh roasting conditions and limited applications, and achieve the effects of simple and convenient operation, control of process parameters, and good application prospects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Weigh 1g RuCl 3 ·nH 2O (n=3~5) was dissolved in 50mL ethanol / water (equal volume ratio, the same below) solution, stirred for 30min, and 0.38M NaHCO was added dropwise 3 ethanol / water solution to make the pH = 8, continue to stir for 30 minutes, let it stand for 5 hours, pour off the upper layer solution, centrifugal filter, wash with deionized water, repeat 3 times, AgNO 3 No white emulsion or precipitate was formed when the solution was tested. Vacuum-dried at 80°C overnight, baked in air at 400°C and 500°C for 30 minutes, and cooled naturally to prepare the anode oxygen evolution catalyst RuO for SPE water electrolysis. 2 , yield about 0.3g.

Embodiment 2

[0032] Weigh 1g of H 2 IrCl 6 (Ir content 37wt%) solution 50mL ethanol / water solution, other steps are with embodiment 1, make SPE water electrolysis anode oxygen evolution catalyst IrO 2 , yield about 0.3g.

Embodiment 3

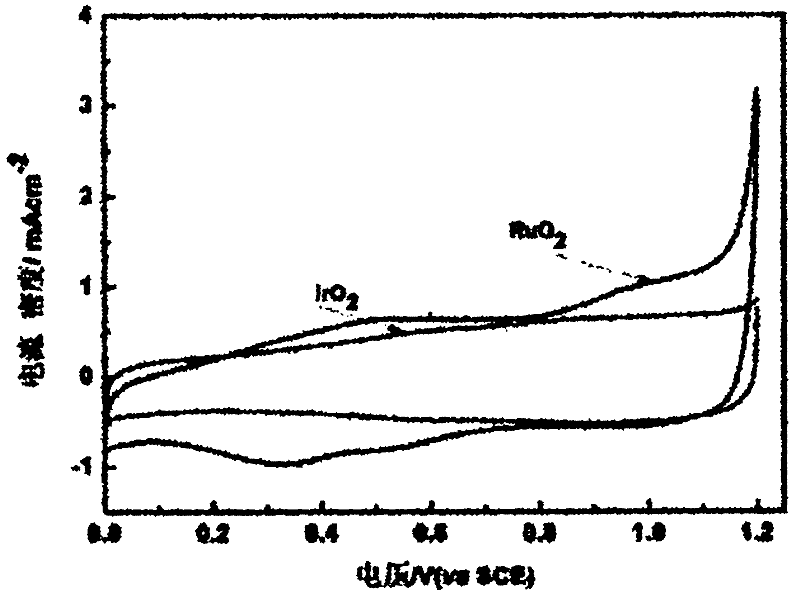

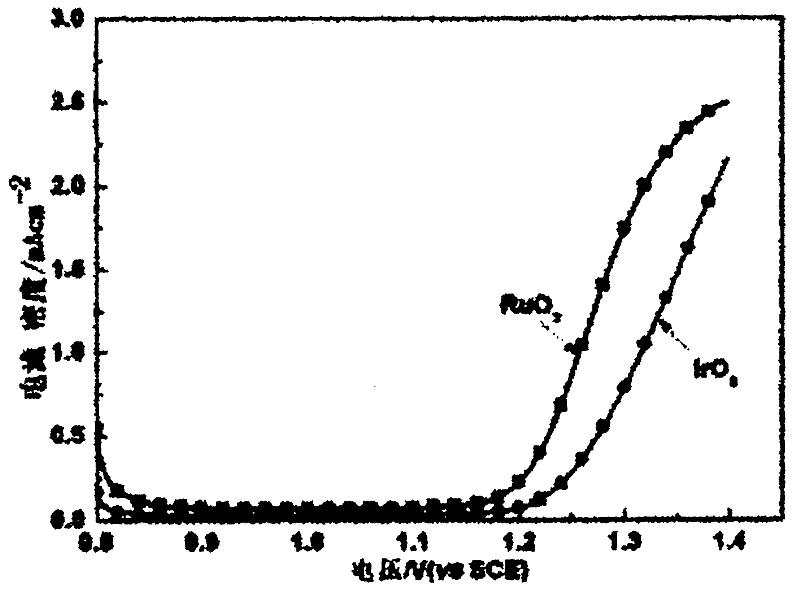

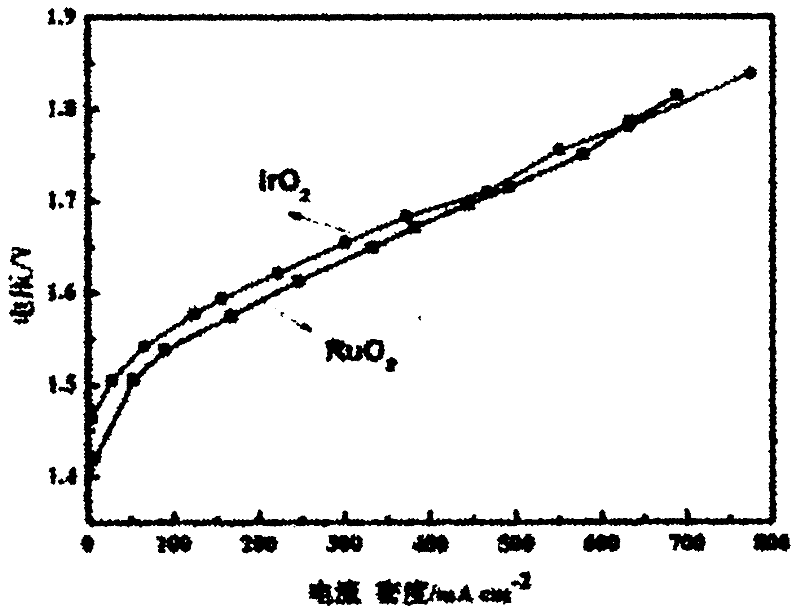

[0034] Weigh 5mg each of the anode catalysts of Example 1 and Example 2, dissolve them in 1mL of absolute ethanol, disperse ultrasonically for 15min, add 50μL of 5wt% Nafion solution dropwise, continue ultrasonically dispersing for 30min, take 25μL and apply Glassy carbon working electrode, with a saturated calomel electrode as a reference electrode and a platinum sheet electrode as a counter electrode to form a classic three-electrode system, at 0.5M H 2 SO 4 In the solution, under the condition of nitrogen flow, the oxygen evolution catalyst prepared in Example 1 and Example 2 was subjected to cyclic voltammetry test and linear scan ( figure 1 and figure 2 ).

[0035] Test results: The Ru(III) / Ru(IV), Ru(IV) / Ru(VI) and Ir(III) / Ir(IV) pairs corresponding to the characteristic redox peaks are very obvious, and the RuO 2 , IrO 2 It has a large electric double layer charging current, and it shows that it has good oxygen evolution activity. Onset oxygen evolution potential...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com