Preparation method of a hydrothermally assisted iron oxyhydroxide-nickel-iron hydrotalcite integrated electrode

An iron oxyhydroxide, hydrothermal assisted technology, applied in the direction of catalyst activation/preparation, chemical instruments and methods, electrodes, etc., can solve the problem of affecting the long-term operation life of the full electrolytic cell, the catalyst particles are difficult to arrange in an orderly manner, and the utilization rate of the catalyst is not high. problems, to achieve good catalytic activity and stability, uniform size, and controllable morphology

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Preparation: (1) water heating once:

[0049] Dissolve 15mM cobalt nitrate and 0.2M urea in 60mL deionized water; stir thoroughly for 30 minutes to obtain a clear and transparent precursor solution; vertically immerse the cleaned foamed nickel into the precursor solution and react hydrothermally at 120°C 8h; vacuum drying at 80°C for 12h;

[0050] (2) Secondary water heating:

[0051] The basic cobalt carbonate nanowire array loaded on nickel foam obtained by hydrothermal treatment is used as the substrate; 0.5mM nickel nitrate and 0.5mM ferric nitrate, 0.6mM ammonium fluoride, 20mM urea, dissolved in 60mL deionized water, at 120℃ Under the condition of hydrothermal reaction for 8h; vacuum drying at 80°C for 12h, a hydrothermally assisted iron oxyhydroxide-nickel-iron hydrotalcite integrated electrode (FeOOH / NiFe LDHs@CCH NAs-NF) was prepared.

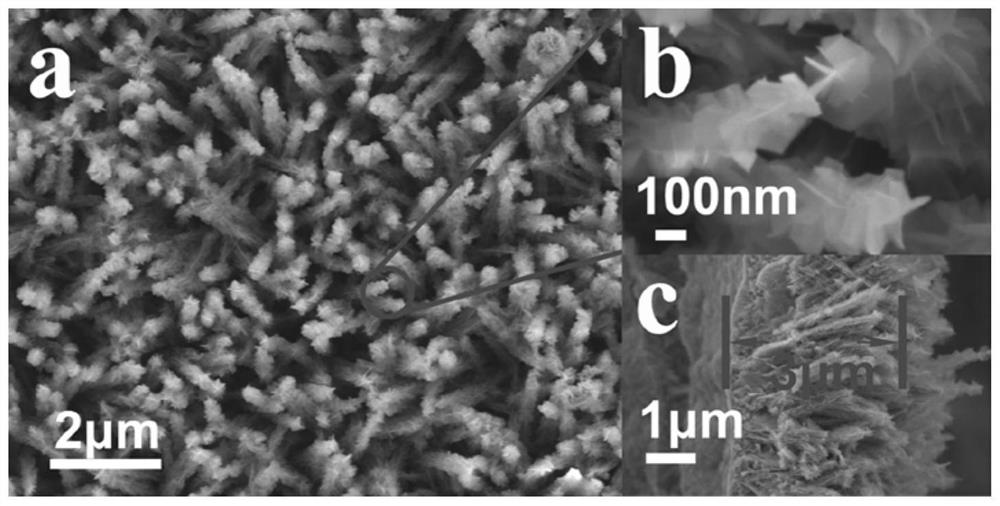

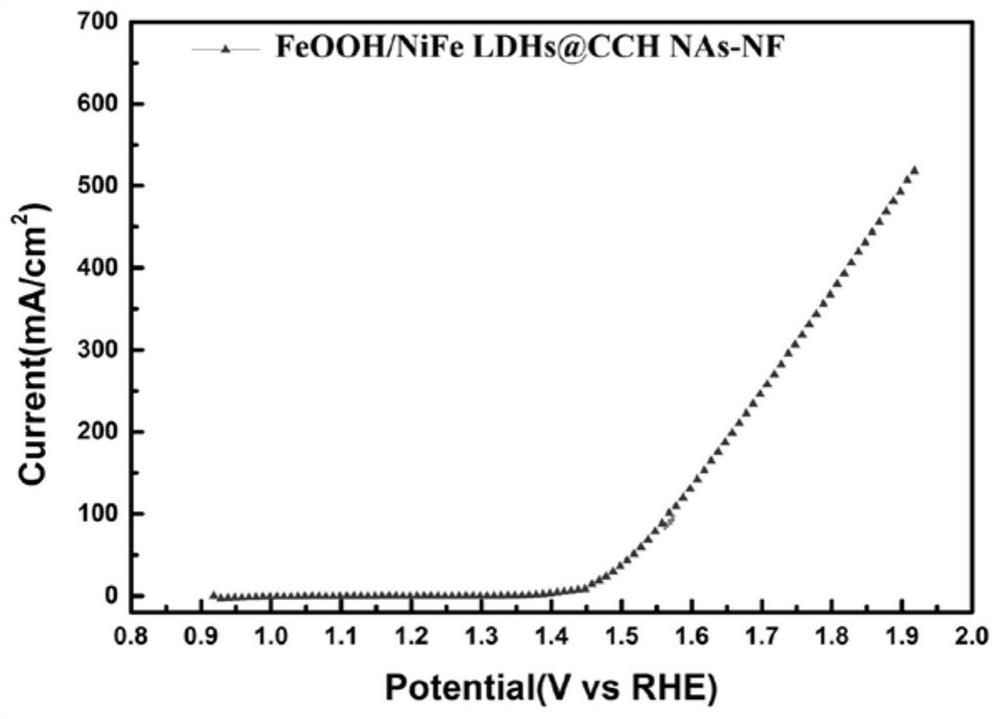

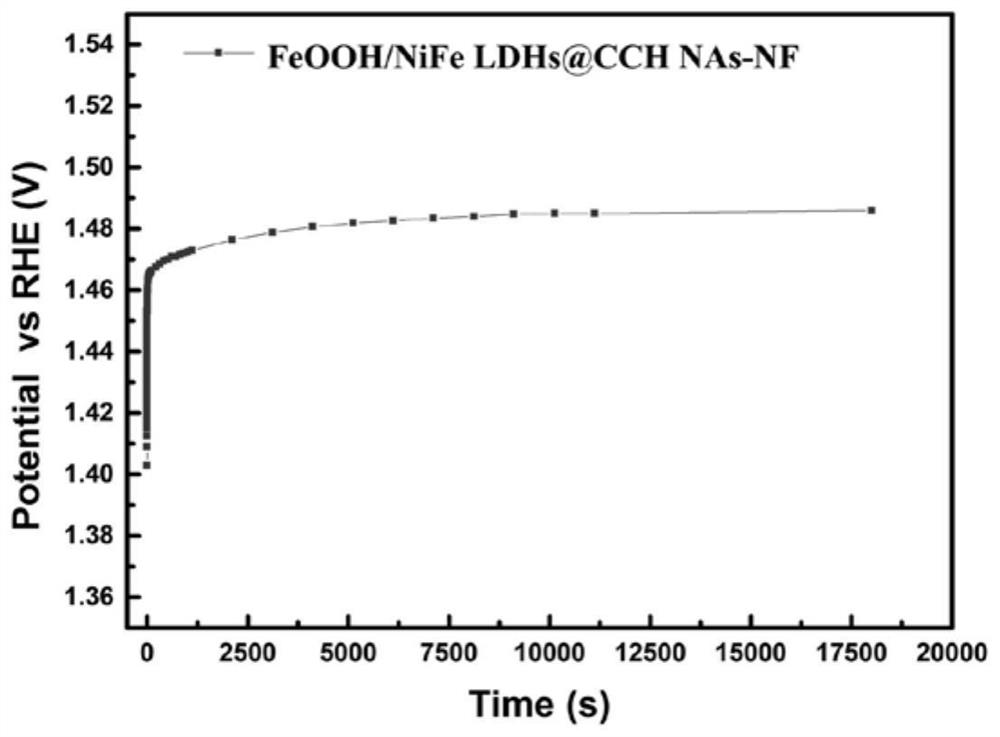

[0052] Depend on figure 1 It can be seen that after two hydrothermal reactions, the controlled synthetic growth on the nick...

Embodiment 2

[0055] As described in Example 1, only the second hydrothermal step was used to prepare an integrated oxygen evolution electrode of iron oxyhydroxide-nickel iron hydrotalcite (FeOOH / NiFe LDHs-NF), 0.5mM nickel nitrate and 0.5mM iron nitrate , 0.6mM ammonium fluoride, 20mM urea, dissolved in 60mL deionized water, hydrothermal reaction at 120°C for 8h; vacuum drying at 80°C for 12h, the hydrothermally assisted iron oxyhydroxide-nickel iron hydrotalcite integrated Oxygen evolution electrode (FeOOH / NiFe LDHs-NF), the test conditions are the same as in Example 1.

[0056] Half-cell test: The half-cell system uses 1M KOH solution saturated with oxygen as the electrolyte, and the integrated electrode performs LSV scanning, such as Figure 4 shown. The integrated electrode prepared by this method is 100mA / cm in 1M KOH electrolyte solution 2 The potential at the electrolysis current density is 1.55V (vs.RHE).

Embodiment 3

[0058] According to the steps described in Example 1, only the basic cobalt carbonate nanowires obtained by the first hydrothermal reaction were loaded on the foamed nickel electrode; at normal temperature, a half-cell test was carried out in a three-electrode system, with 1M KOH solution as the electrolyte, Polarization curves obtained by performing linear voltammetry scans. Test condition is the same as embodiment 1.

[0059] Half-cell test: The half-cell system uses 1M KOH solution saturated with oxygen as the electrolyte, and the integrated electrode performs LSV scanning, such as Figure 5 shown. The integrated electrode prepared by this method has a potential of 1.678V (vs. RHE) under the electrolytic current density of 100mA / cm2 in 1M KOH electrolyte solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com