Silica cross-linking shape memory polymer material

A technology of memory polymer and silicon dioxide, which is applied in the field of shape memory polymer materials, can solve the problems of less chemical bonding points and weak bonding force, and achieve high mechanical strength, improved mechanical properties, and improved mechanical strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

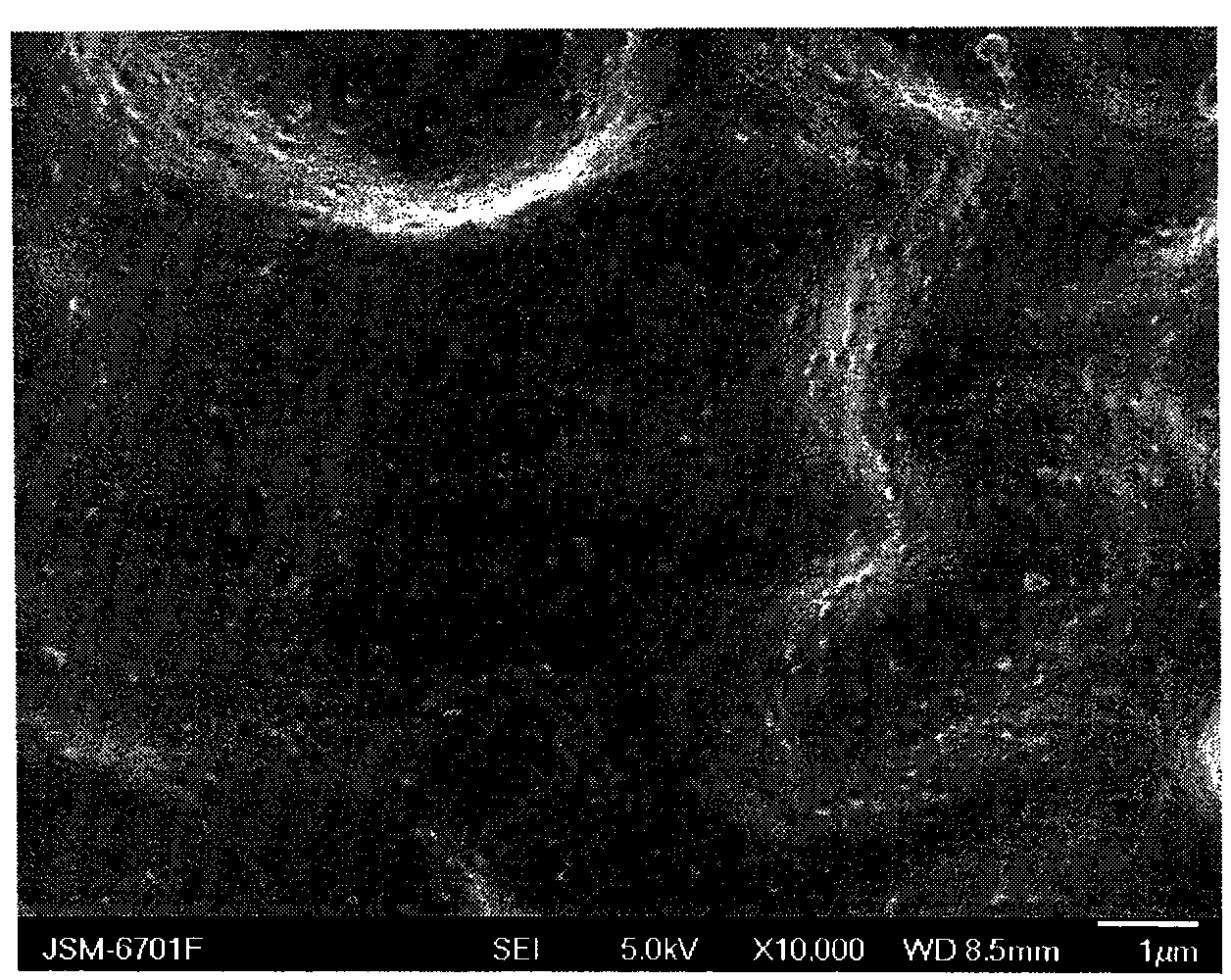

[0028] Preparation of silica cross-linked shape memory polymer (140nm silica particles): Weigh 0.1g of silica particles with a particle diameter of about 140nm, add 5.6979gε-caprolactone, and ultrasonically disperse for 3 hours to obtain a uniform dispersion clear colloidal fluid. Add 2% initiator stannous octoate, in N 2 Stirring and reacting at 130°C for 20 hours under the same conditions, SiO with high viscosity was obtained 2 PCL polymer, dissolve the polymer with dichloromethane, filter to remove impurities, add n-hexane to precipitate white polymer powder, wash and filter to remove unreacted monomer, and obtain SiO with a particle size of about 400nm after vacuum drying at 45°C 2 PCL spherical polymer particles. Weigh 2g of SiO 2 PCL was dissolved in 20gDMF, in N 21 g of MDI was added at low temperature, stirred and reacted at 80°C for 2 hours to obtain a white emulsion, which was cast in a polytetrafluoroethylene mold at 80°C to remove the solvent to obtain a shape-...

Embodiment 2

[0035] Preparation of silica cross-linked shape memory polymer (370nm silica particles) and material characterization and shape memory performance test: select 370nm silica particles, follow-up steps are the same as in Example 1, first synthesize SiO 2 PCL polymer pellets (with a particle size of about 2 μm) were added into MDI for reaction and then cast in a glass mold, and dried at 80° C. to remove the solvent.

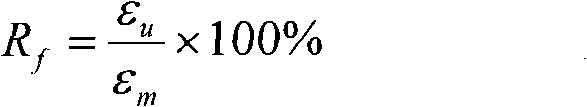

[0036] The shape fixation rate and shape recovery rate were tested by the method of Example 1. R at 100% deformation f and R r Both are 100%, and when the deformation is 300% and 500%, R f and R r After the second cycle, it can reach more than 95%.

Embodiment 3

[0038] According to the 140nm silicon dioxide particles prepared in Example 1, weigh the 140nm silicon dioxide particles of 0.1g respectively, and in the ε-caprolactone of 7.5968g, prepare SiO as in Example 1 2 PCL polymer pellets (particle size about 700nm), then add MDI to react and then cast.

[0039] The shape fixation rate and shape recovery rate were tested by the method of Example 1. R at 100% deformation f and R r Both are 100%, and when the deformation is 300% and 500%, R f and R r After the second cycle, it can reach more than 99%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com