A kind of numerical control automatic grinding machine used for punching mold processing and using method thereof

A mold processing and grinding machine technology, applied in the field of grinding machines, can solve the problems of poor cooling effect, harsh grinding environment, and low equipment life, and achieve the effects of avoiding annealing, improving grinding accuracy and prolonging service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

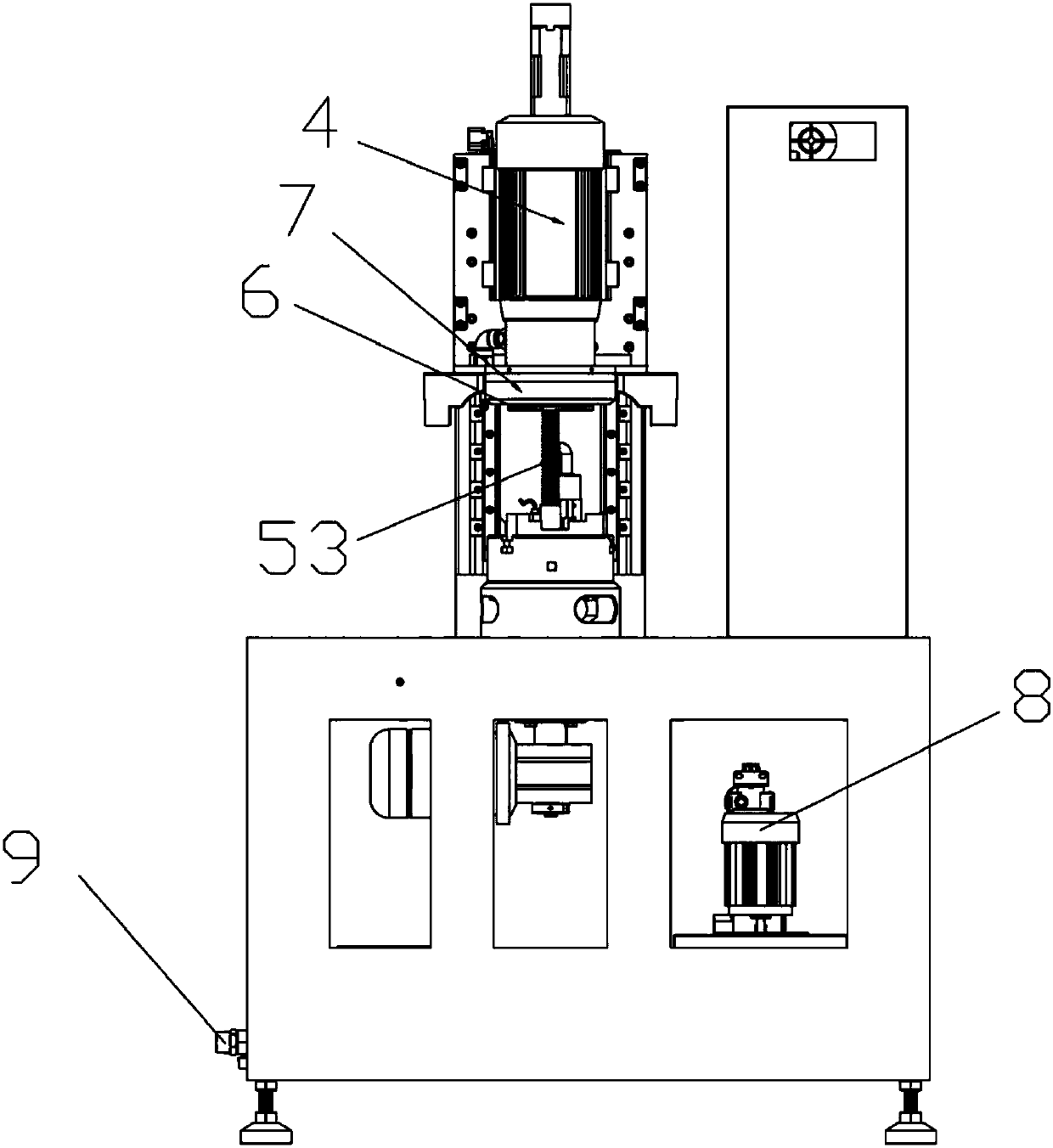

[0047] Such as figure 1 with figure 2 As shown, a numerically controlled automatic grinding machine for punch mold processing includes a main shaft grinding wheel base 1, a grinding head motor 4 arranged on the main shaft grinding wheel base 1, a grinding wheel 6 arranged on the grinding head motor 4, and cooling water Disk 7; the cooling water disk 7 is a hollow disc shape, which is arranged between the grinding head motor 4 and the grinding wheel 6, and surrounds the main shaft between the grinding head motor 4 and the grinding wheel 6; the inner wall of the cooling water disk 7 is provided with spray holes; such as figure 1 As shown, the main shaft grinding wheel seat 1 is a closed structure, which is wrapped outside the grinding head motor 4 and the cooling water pan 7; figure 2 As shown, the cooling water pan 7 provides cooling liquid through the cooling liquid pump 8 connected thereto, and the water outlet valve 9 is connected with the cooling liquid pump 8 to realiz...

Embodiment 2

[0051] Same as Example 1, the difference is: as figure 1 with Figure 4 As shown, the lifting device 5 that drives the main shaft grinding wheel seat 1 to lift includes a servo motor 51, a screw rod 52 connected to the servo motor, and a screw nut seat 53 sleeved on the screw screw 52; the screw nut seat 53 is fixedly connected with the main shaft grinding wheel seat 1 ;Such as figure 1 As shown, a guide rail vertical plate 12 is also included, and the guide rail vertical plate 12 is arranged between the main shaft grinding wheel seat 1 and the lifting device 5;

[0052] The lifting device in this embodiment can realize automatic lifting up and down of the grinding wheel seat of the main shaft, which improves the automation performance; the structure of the lifting device is more stable by setting the guide rail vertical plate.

Embodiment 3

[0054] Same as embodiment 2, the difference is: as figure 1 shown, as Figure 5 As shown, the side of the upper casing 10 facing the main shaft grinding wheel seat 1 is provided with a horizontal double-opening door 11; the horizontal double-opening door 11 is provided with a safety sensor alarm.

[0055] In this embodiment, setting the horizontal double-opening door has the advantages of flexible operation and high safety performance; setting a safety sensor alarm, when the machine tool is running, the protective door is opened, the power is automatically cut off and the alarm is stopped, and the safety is high;

[0056] A method for using a numerically controlled automatic grinding machine for processing punch dies, comprising the following steps:

[0057] 1) Clamp the workpiece on the chuck of the workbench, and close the horizontal double door;

[0058] 2) Turn on the power of the laser tool setting sensor to perform tool setting;

[0059] 3) Start the motor of the grin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com