A thermoforming method for mixed-braided continuous fiber reinforced thermoplastic structural panels

A technology for reinforcing thermoplastic and continuous fibers, applied in the field of continuous fiber reinforced thermoplastic composite materials, can solve the problems of easy sliding of fibers, affect performance, waves, etc., and achieve the effect of tight fiber criss-cross, lower production costs, and low process requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Glass fiber S reinforced polypropylene prepreg and glass fiber E reinforced polypropylene prepreg, the weight ratio is 1:2. Two prepregs with a width of 0.1m were placed on the creel of the weaving machine to weave evenly, and the two prepregs were woven into a mesh prepreg tape with a width of 1.2m. The glass fiber E reinforced polypropylene prepreg is the main body in the prepreg tape, and the glass fiber S reinforced polypropylene prepreg is uniformly dispersed in it.

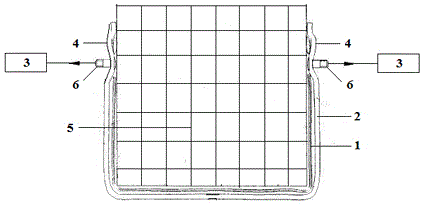

[0027] Such as figure 1 As shown, the prepreg tape 1 is cut to the same size as the mold 5, placed in the mold 5, covered with a vacuum bag 2 (or polyester film), the size of the vacuum bag 2 is larger than the size of the mold 5, and the surrounding area of the vacuum bag Fix and seal with clamping and sealing device 4, vacuum nozzle 6 is preset on vacuum bag 2, and its position is determined according to the shape of the mould. Connect the vacuum nozzle 6 to a vacuum pump or other vacuuming devi...

Embodiment 2

[0030] Carbon fiber reinforced nylon 1010 prepreg and glass fiber reinforced nylon 1010 prepreg, the weight ratio is 5:2. Two kinds of prepregs with a width of 0.1m were respectively placed on the creel of the weaving machine to weave evenly, and the two kinds of prepregs were woven into a sheet-like prepreg tape with a width of 1.4m. In the prepreg, the carbon fiber reinforced nylon 1010 prepreg is the main body, and the glass fiber reinforced nylon 1010 prepreg is uniformly dispersed therein.

[0031] Cut the prepreg tape to the same size as the mold, lay it in the mold, cover it with a vacuum bag (or polyester film), the size of the vacuum bag is larger than the size of the mold, fix and seal the periphery of the vacuum bag with a clamping sealing device, The vacuum nozzle is preset on the vacuum bag, and its position is determined according to the shape of the mold. Connect the vacuum nozzle to the vacuum pump (or other vacuuming device), start electric heating (or oil he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com