Drilling-cutting-linked coal layer gas drainage and outburst prevention system and method based on ultra-long drilling and high-pressure water jetting

A technology of high-pressure water jet and coal seam gas, which is applied in the direction of gas discharge, cutting machinery, earthwork drilling and mining, etc., can solve the problems of poor drainage effect and achieve the effect of increasing the range of gas release, ingenious structure and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0043] This embodiment is a preferred implementation mode of the present invention, and other principles and basic structures that are the same or similar to this embodiment are within the protection scope of the present invention.

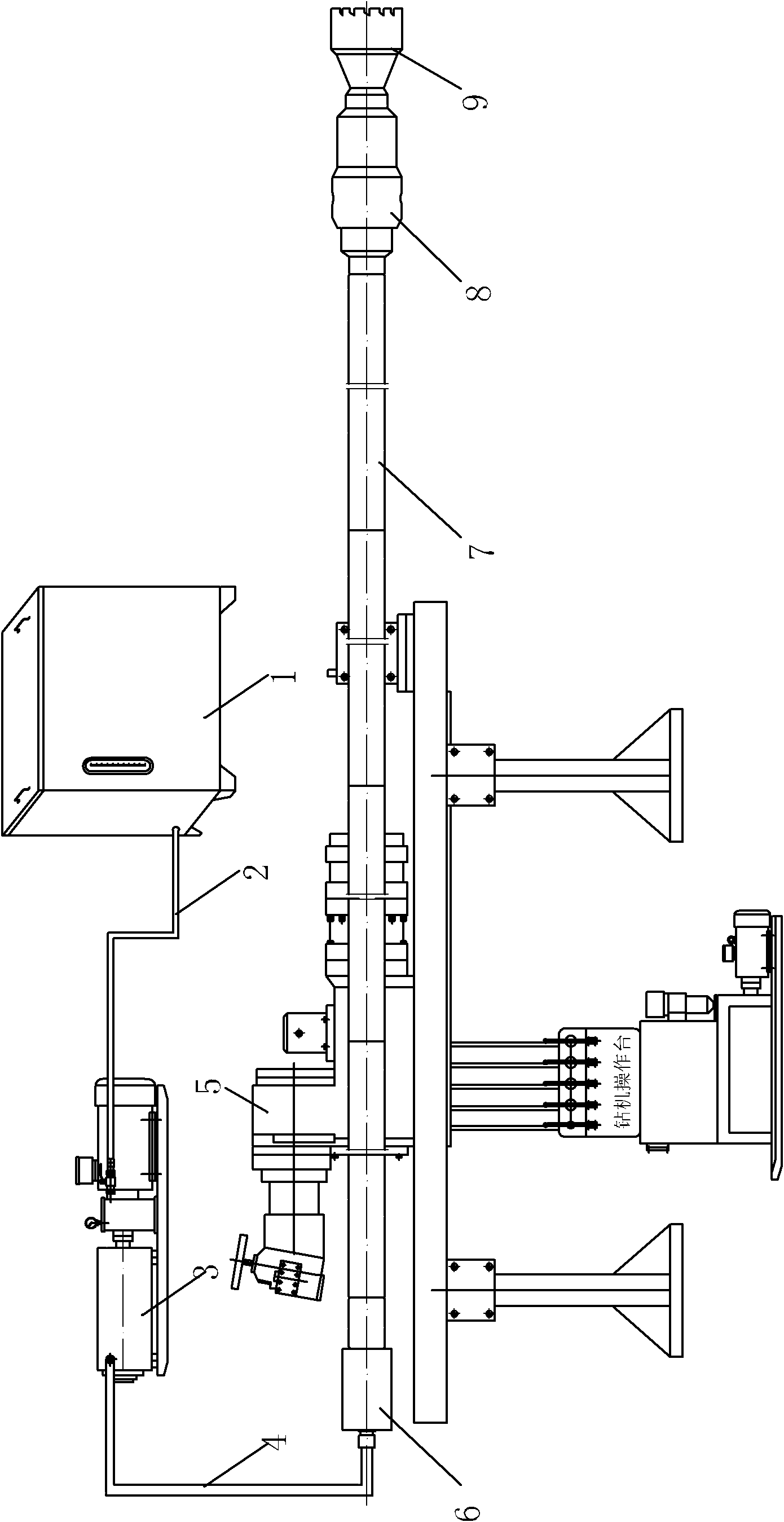

[0044] Please see attached figure 1 , the system of the present invention mainly includes a drill bit 9, a pressure sensing valve 8, a drill pipe 7, a drilling rig 5, a high and low pressure water delivery rotating device 6, a high pressure pump 4 and a water tank 1. In this embodiment, the pressure sensing valve 8 is installed on the drill pipe 7 Front end, pressure sensing valve 8 can automatically adjust the direction and flow of water according to the size of the water pressure. During the drilling process, the drill bit 9 is cooled and the slag is discharged; when the pressure of the water increases to a certain pressure, the pressure sensing valve 8 automatically blocks the low-pressure water outlet hole, and the water can only be sprayed ou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com