Comprehensive utilization method of waste water of production of brominated butyl rubber

A technology of bromobutyl rubber and production wastewater, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problems of difficult discharge and high salinity of production wastewater, and achieve High utilization efficiency, simple method, and the effect of solving the difficult discharge of high-concentration sodium bromide-containing wastewater

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

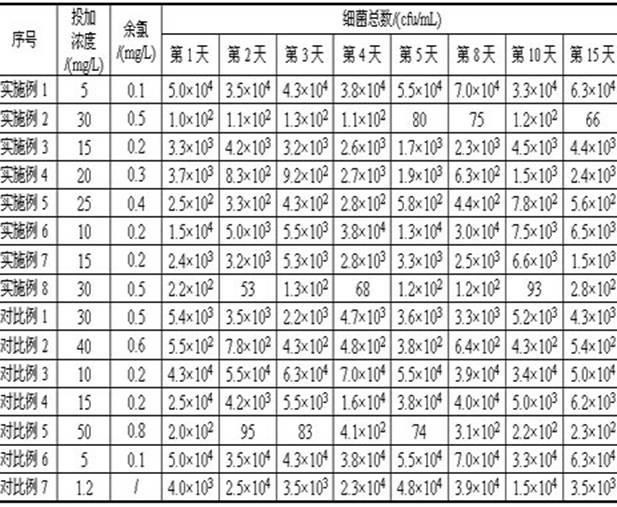

[0022] Under the condition of operating pressure of 2.0MPa, the bromobutyl rubber production wastewater with a sodium bromide mass concentration of 1.08% was subjected to reverse osmosis concentration treatment using a coiled membrane module equipped with an aromatic polyamide composite membrane to obtain sodium bromide A concentrated solution with a mass concentration of 10.5%; dissolve sodium hypochlorite in the above concentrated solution to form a mixed sterilizing solution, control the mixing molar ratio of the concentrated solution (calculated as bromine) and sodium hypochlorite (calculated as chlorine) to 1:0.5, and use the mixed sterilizing solution The dynamic simulation test was carried out, and the dosing concentration and results are shown in Table 2.

Embodiment 2

[0024] Under the condition of an operating pressure of 8.0MPa, the bromobutyl rubber production wastewater with a sodium bromide mass concentration of 0.95% was subjected to reverse osmosis concentration treatment by using a coiled membrane module equipped with a polysulfone composite membrane to obtain the mass concentration of sodium bromide A concentrated solution with a concentration of 14.7%; trichloroisocyanuric acid is dissolved in the above concentrated solution to form a mixed sterilizing solution, and the mixing molar ratio of the concentrated solution (calculated as bromine) to trichloroisocyanuric acid (calculated as chlorine) is controlled The ratio is 1:1, and the dynamic simulation test is carried out with the mixed bactericidal solution. The dosage concentration and the results are shown in Table 2.

Embodiment 3

[0026] Under the conditions of operating temperature of 50°C and pressure of 8KPa, the bromobutyl rubber production wastewater with a mass concentration of sodium bromide of 1.22% was concentrated by membrane distillation using a flat-plate membrane module equipped with a polytetrafluoroethylene hydrophobic membrane. , to obtain a concentrated solution with a sodium bromide mass concentration of 12.3%; dissolve sodium dichloroisocyanurate in the above concentrated solution to form a mixed sterilizing solution, and control the concentration (in terms of bromine) and sodium dichloroisocyanurate ( The mixing molar ratio (calculated as chlorine) is 1:1.2, and the dynamic simulation test is carried out with the mixed sterilizing solution, and the dosage concentration and results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| salt rejection rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com