Cam grinding device

A cam and grinding technology, which is applied in the direction of grinding/polishing equipment, turning equipment, cams, etc., can solve the problems of increasing grinding time, inaccurate grinding of a single cam, and inaccurate grinding, so as to reduce the grinding time , The effect of reducing the grinding cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

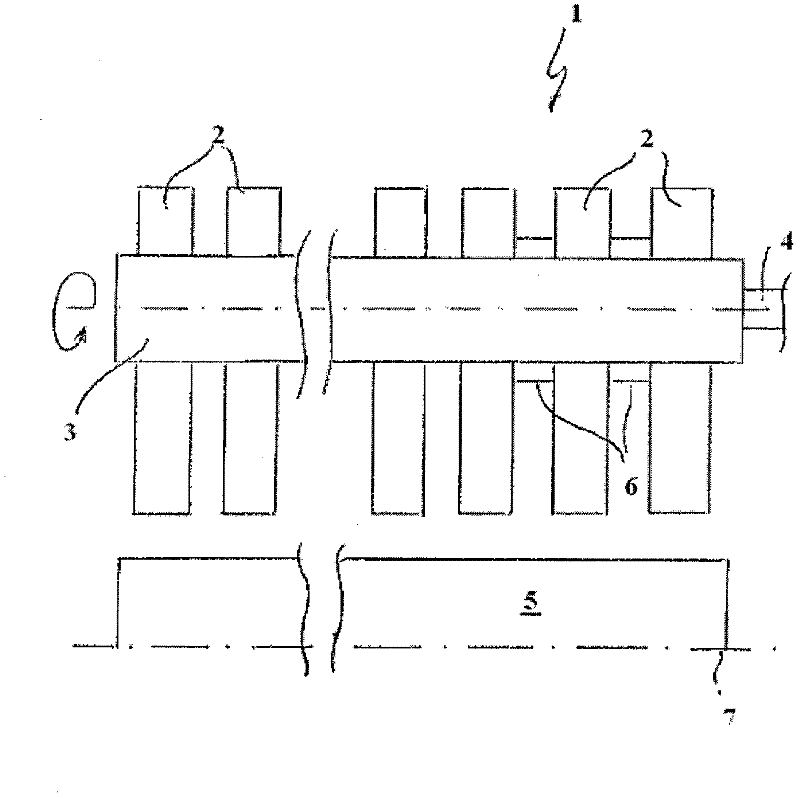

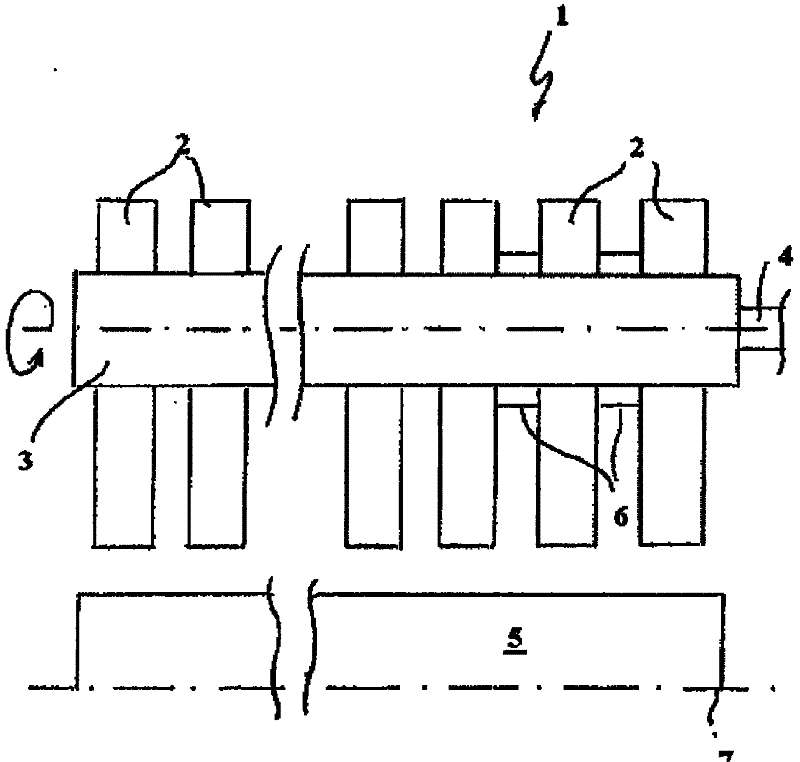

[0012] Such as figure 1 As shown in , the device 1 according to the invention for grinding a cam 2 has a holding mandrel 3 on which the cam 2 is non-rotatably fixed during the grinding operation. According to the invention, such a holding mandrel 3 is preferably formed, at least in some regions, predominantly from ceramics, in particular technical ceramics. In this case, the holding spindle 3 is connected in a non-rotatable manner to a shaft 4 of a drive device (not shown). According to the invention, since the retaining mandrel 3 is formed of ceramic, said mandrel has a high modulus of elasticity and a high strength associated therewith. This makes it possible to grind a plurality of cams 2 , preferably eg eight cams 2 , simultaneously by pressing the cams 2 against the grinding elements 5 of the device 1 . The grinding element 5 itself typically has a rapidly rotating grinding body which is pressed against the cam 2 clamped on the holding arbor 3 . It goes without saying ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com