Inferior heavy oil contact cracking-gasification combined treatment method

A technology of contact cracking and low-quality heavy oil, applied in chemical instruments and methods, sustainable manufacturing/processing, granular/powdered fuel gasification, etc., to increase concentration, reduce gasification reaction temperature, and avoid high-temperature hydrothermal deactivation Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

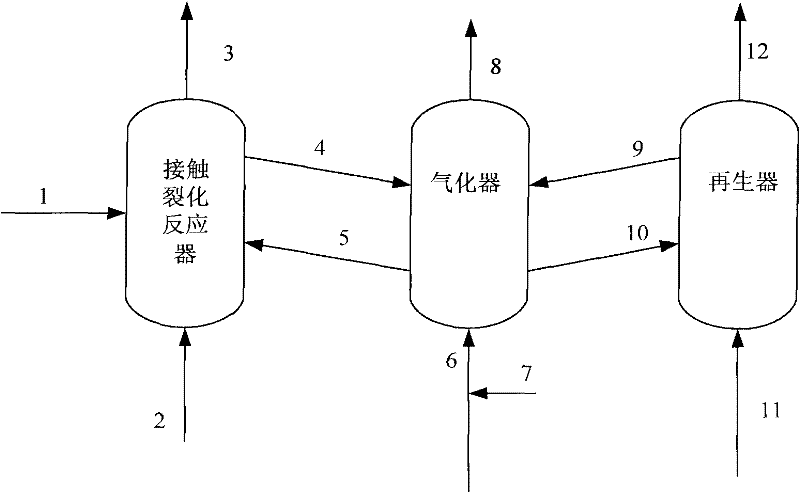

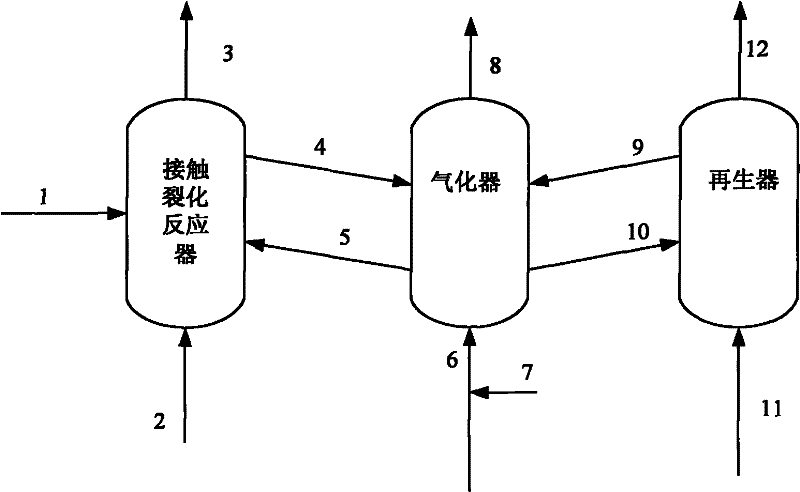

Method used

Image

Examples

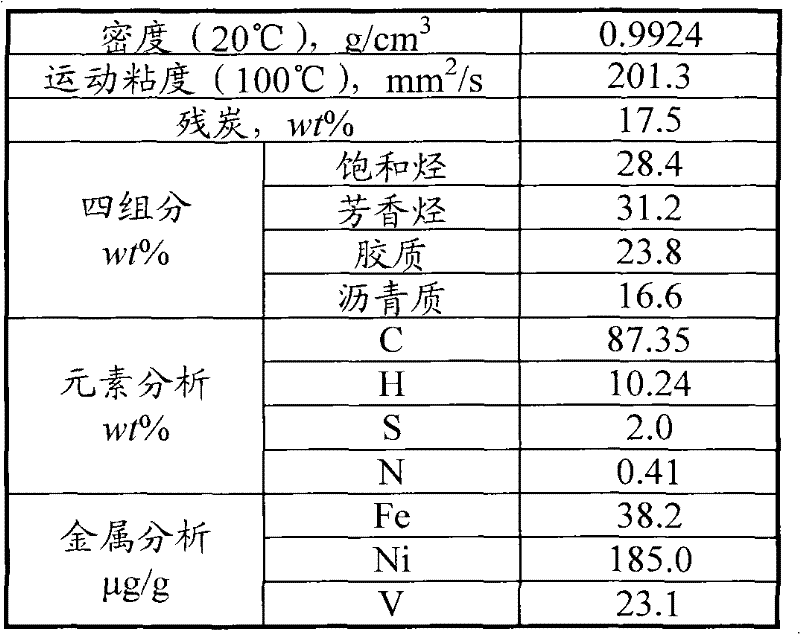

Embodiment 1

[0051] The cracking catalyst containing Y molecular sieve (the brand name is MMC-2, produced by Qilu Catalyst Branch of Sinopec Corporation) and CaO with nanometer size are carried out after mixing, beating, spray drying and roasting with a weight ratio of 1:1 by using spray drying technology, Defined as contact agent-1.

[0052] In a fixed fluidized bed reactor, the contact agent-1 was contacted and reacted with the vacuum residue (see Table 1 for its properties), the reaction temperature was 500°C, the agent-oil ratio was 18.0, and the weight hourly space velocity was 4.0h -1 . The reaction temperature of the gasification reactor is 600°C, and the volume ratio of oxygen and water vapor is 45:55. The distribution of cracking and gasification reaction products is shown in Table 2. After partial gasification, the carbon content of the contact agent is 0.42wt%, and it enters the regenerator, and is regenerated by feeding oxygen at a regeneration temperature of 850°C.

Embodiment 2

[0057] After the waste catalytic cracking catalyst containing Y molecular sieve (trade name MLC-500, produced by Qilu Catalyst Branch of Sinopec Corporation) and MgO were mechanically mixed at a weight ratio of 5:1, the mixture was defined as contact agent-2.

[0058] In a fixed fluidized bed reactor, the contact agent-2 is contacted and reacted with the vacuum residue, the reaction temperature is 480°C, the agent-oil ratio is 10.0, and the weight hourly space velocity is 10.0h -1 , the reaction temperature of the gasification reactor is 700°C, and the volume ratio of oxygen and water vapor is 30:70. The distribution of cracking and gasification reaction products is shown in Table 2. After partial gasification, the carbon content of the contact agent is 0.50wt%, and it enters the regenerator, and is regenerated by feeding oxygen at a regeneration temperature of 900°C.

Embodiment 3

[0063] Cracking Catalyst MLC-500 and Ca(OH) Containing Y Molecular Sieve 2 After mechanical mixing at a weight ratio of 1:5, the mixture was defined as contact agent-3.

[0064] In a fixed fluidized bed reactor, the contact agent-3 is contacted and reacted with the vacuum residue, the reaction temperature is 560°C, the agent-oil ratio is 5.0, and the weight hourly space velocity is 20.0h -1 , the reaction temperature of the gasification reactor is 650°C, and the volume ratio of oxygen and water vapor is 40:60. The distribution of cracking and gasification reaction products is shown in Table 2. After partial gasification, the contact agent has a carbon content of 0.75wt%, enters the regenerator, and is regenerated by feeding oxygen at a regeneration temperature of 950°C.

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com