Film solar battery based on crystalline silicon and formation method thereof

A technology for solar cells and thin films, which is applied to circuits, photovoltaic power generation, electrical components, etc., can solve the problems of contaminating the I-type amorphous silicon layer 13, reducing the photoelectric conversion efficiency of thin-film solar cells, and reducing the band gap width of thin-film solar cells, etc. Achieve the effect of improving photoelectric conversion efficiency, reducing pollution and increasing band gap width

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

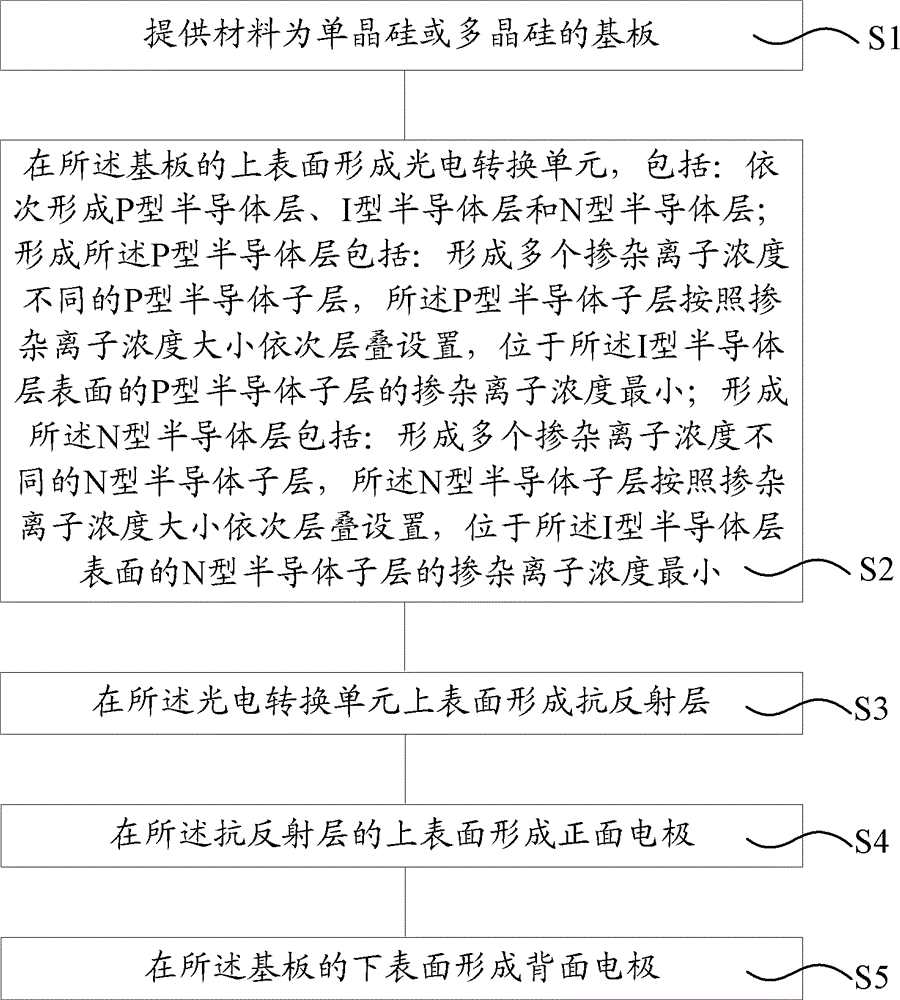

[0064] refer to figure 2 As shown, this embodiment provides a method for forming a thin-film solar cell based on crystalline silicon, including:

[0065] Step S1, providing a substrate made of monocrystalline silicon or polycrystalline silicon;

[0066] Step S2, forming a photoelectric conversion unit on the upper surface of the substrate, including: sequentially forming a P-type semiconductor layer, an I-type semiconductor layer, and an N-type semiconductor layer; forming the P-type semiconductor layer includes: forming a plurality of dopant ion concentration Different P-type semiconductor sub-layers, the P-type semiconductor sub-layers are sequentially stacked according to the doping ion concentration, and the P-type semiconductor sub-layer located on the surface of the I-type semiconductor layer has the smallest doping ion concentration; forming the N The N-type semiconductor layer includes: forming a plurality of N-type semiconductor sub-layers with different doping ion ...

Embodiment 2

[0118] This embodiment provides a method for forming a thin-film solar cell based on crystalline silicon, including:

[0119] The materials provided are monocrystalline silicon or polycrystalline silicon substrates;

[0120] An I-type semiconductor layer and a P-type semiconductor layer are sequentially formed on the substrate. The P-type semiconductor layer includes a plurality of P-type semiconductor sublayers with different dopant ion concentrations. The sizes are stacked in sequence, and the dopant ion concentration of the P-type semiconductor sub-layer located on the surface of the I-type semiconductor layer is the smallest.

[0121] Wherein, the substrate may be an N-type substrate.

[0122] Wherein, the steps of forming the I-type semiconductor layer and the P-type semiconductor layer are the same as those in Embodiment 1, and will not be repeated here. In this embodiment, the P-type semiconductor layer includes four P-type semiconductor sub-layers as an example.

[...

Embodiment 3

[0132] This embodiment provides a method for forming a thin-film solar cell based on crystalline silicon. The difference from Embodiment 2 is that in this embodiment, after forming the P-type semiconductor layer, an N-type semiconductor layer is also formed on the P-type semiconductor layer. .

[0133] Wherein, the dopant ion concentration in the N-type semiconductor layer may be evenly distributed, or may include multiple N-type semiconductor sub-layers with different dopant ion concentrations, which does not limit the protection scope of the present invention.

[0134] Specifically, refer to Figure 10 As shown, the thin-film solar cells based on crystalline silicon formed by the method of this embodiment include:

[0135] Substrate 30;

[0136] The I-type semiconductor layer 31, the P-type semiconductor layer 32, the N-type semiconductor layer 33, the anti-reflection layer 34 and the front electrode 35 which are located above the substrate 30 in turn; the P-type semicondu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com