Aqueous adhesive for non-woven fabric composite membrane and preparation method of aqueous adhesive

A composite film and adhesive technology, applied in the direction of adhesive types, ester copolymer adhesives, hydrocarbon copolymer adhesives, etc., can solve the problems of poor environmental protection, damage to the health of users, etc., and achieve good stability , The effect of improving adhesion and good wettability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The above-mentioned preparation method for the water-based adhesive of the non-woven composite film specifically comprises the following steps:

[0032] Pre-emulsification: Put into the emulsification kettle the deionized water accounting for 40-50% of the total weight of deionized water, the alkylphenol ether phenol ammonium sulfate accounting for 50-60% of the total weight of alkylphenol ether phenol ammonium sulfate in the emulsifier, accounting for Sodium vinyl sulfonate with a total weight of 70-80% of sodium vinyl sulfonate and all monomers, started stirring and emulsifying for more than 30 minutes to obtain a pre-emulsion;

[0033] Seed reaction: put 40-45% of the total weight of deionized water into the reactor, the remaining ammonium alkylphenol ether ammonium sulfate in the emulsifier, the remaining sodium vinyl sulfonate, and buffering agent, start stirring and raise the temperature , when the temperature reaches 75°C, put 5-10wt% of the pre-emulsion obtained...

Embodiment 1

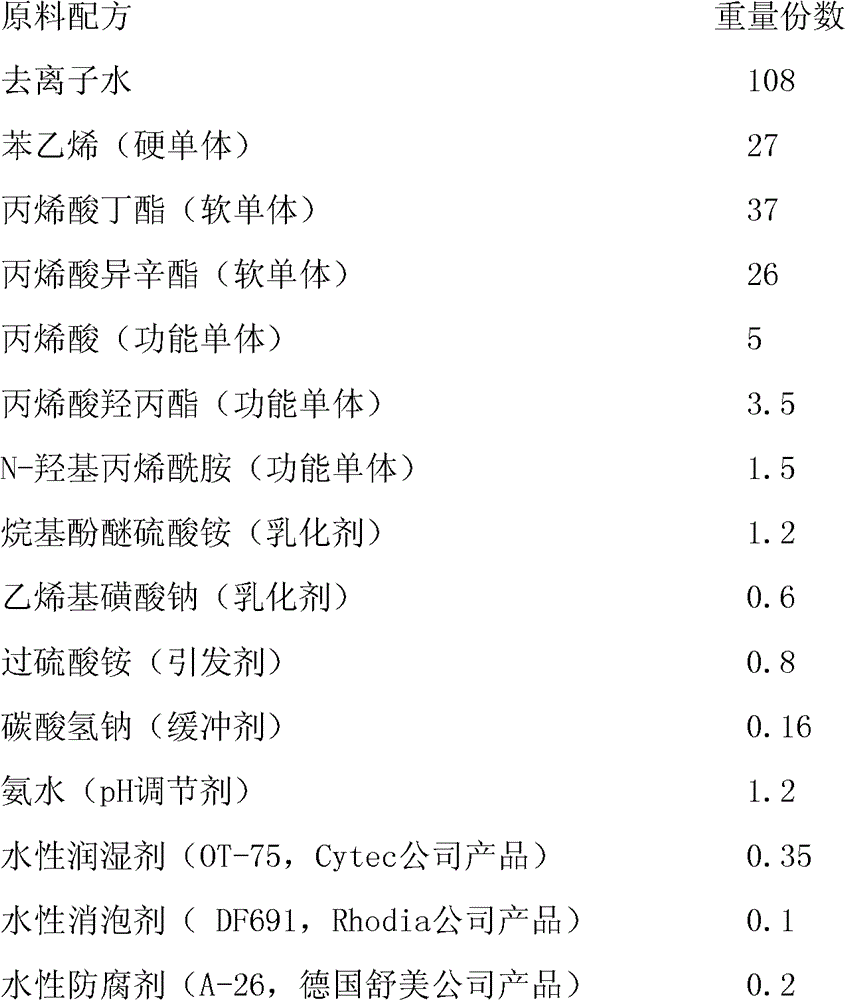

[0038] This embodiment provides a water-based adhesive for non-woven fabric composite film, which is a water-based composite adhesive with good wettability and better wettability with non-woven fabric, and can be used in non-woven fabric composite film , with high peel strength. The raw materials and consumption of this water-based adhesive are as follows:

[0039]

[0040] The preparation method of above-mentioned water-based adhesive is as follows:

[0041] (1) Pre-emulsification: drop into the emulsification kettle into deionized water accounting for 50% of the total weight of deionized water, alkylphenol ether ammonium sulfate accounting for 60% of the total weight of alkylphenol ether ammonium sulfate, accounting for the total weight of sodium vinylsulfonate 80% by weight of sodium vinyl sulfonate and all monomers, started stirring and emulsifying for more than 30 minutes to obtain a pre-emulsion;

[0042] (2) Seed reaction: drop into the reactor and account for 40% ...

Embodiment 2

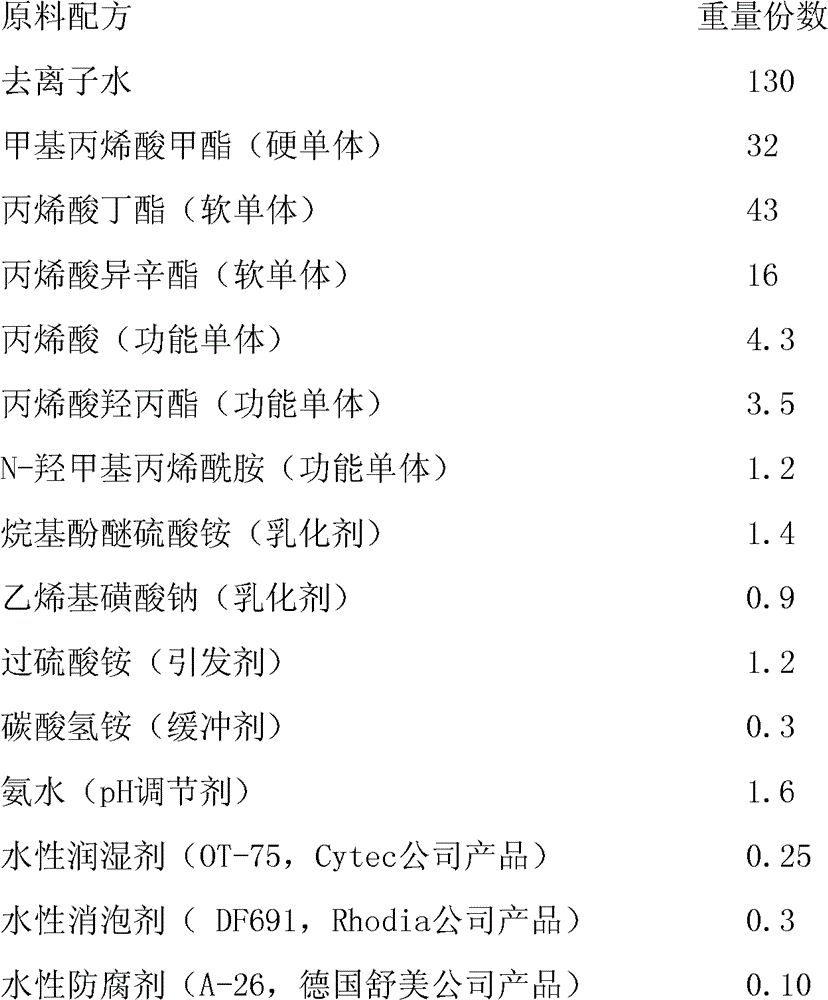

[0046] This embodiment provides a water-based adhesive for non-woven fabric composite film, which is a water-based composite adhesive with good wettability and better wettability with non-woven fabric, and can be used in non-woven fabric composite film , with high peel strength. The raw materials and consumption of this water-based adhesive are as follows:

[0047]

[0048] The preparation method of above-mentioned water-based adhesive is as follows:

[0049] (1) Pre-emulsification: drop into the emulsification tank and account for 45% of the total weight of deionized water, and account for 55% of the total weight of alkylphenol ether ammonium sulfate. 75% by weight of sodium vinyl sulfonate and all monomers, started stirring and emulsifying for more than 30 minutes to obtain a pre-emulsion;

[0050] (2) Seed reaction: drop into the reactor and account for 45% of the total weight of deionized water, the remaining alkylphenol ether ammonium sulfate and the remaining sodium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com